Distributed feedback light waveguide laser

A distributed feedback, optical waveguide technology, applied in the field of optoelectronics, can solve the problems of complex phase-shift grating, low yield, and difficulty in manufacturing DFB optical waveguide lasers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

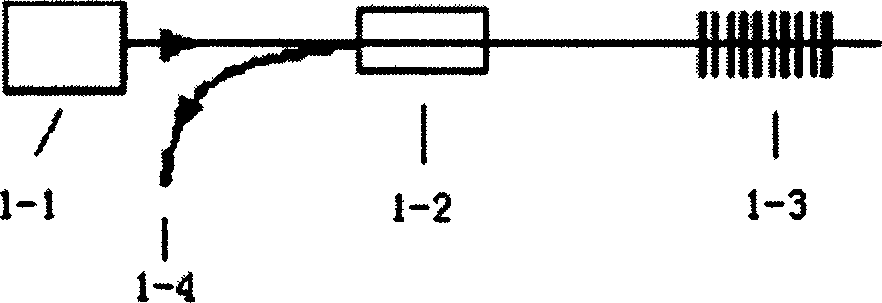

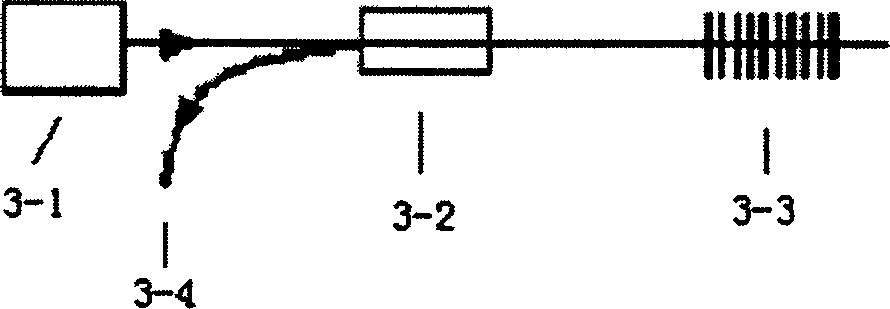

[0050] The manufacturing method of the DFB fiber laser based on the equivalent phase shift sampling fiber grating of the present invention is divided into two parts: one is the design and manufacture of the equivalent phase shift sampling fiber grating, and the other is the manufacturing of the DFB fiber laser. Concrete implementation example is described in detail as follows in conjunction with accompanying drawing:

[0051] 1. Design and manufacture of equivalent phase-shift sampling fiber grating

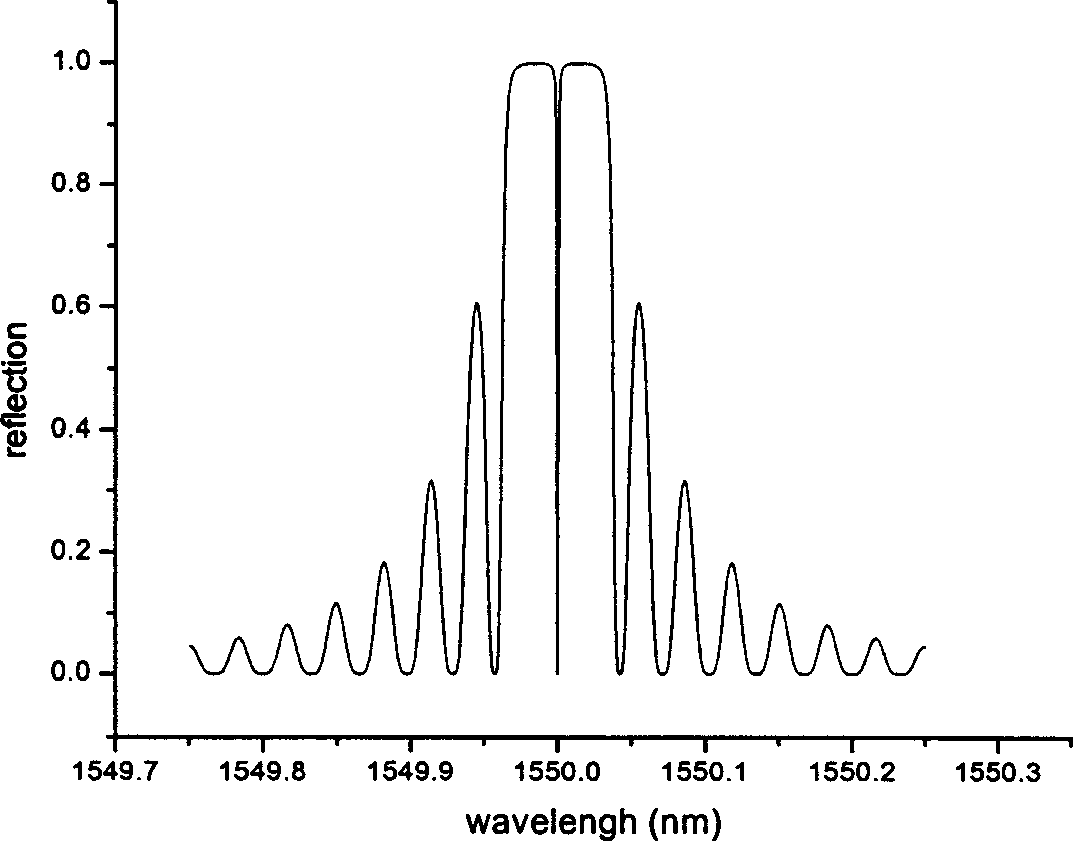

[0052] This experiment is made with a chirped template. According to the literature, to compensate for the chirp of the grating period introduced by the template at the -1 level peak, it is necessary to compensate the grating period chirp caused by the template by changing the sampling period of the grating. Specifically is the formula z n + a z n 2 = n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com