Tripolar carbon nanotube display with filtering structure and process for preparing same

A technology of carbon nanotubes and carbon nanotube cathodes, which is applied in the field of triode flat-panel displays and their manufacturing processes, can solve the problems of weakening the high brightness of displayed images and increasing the blackness of the display screen, and achieve the effect of increasing quality and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

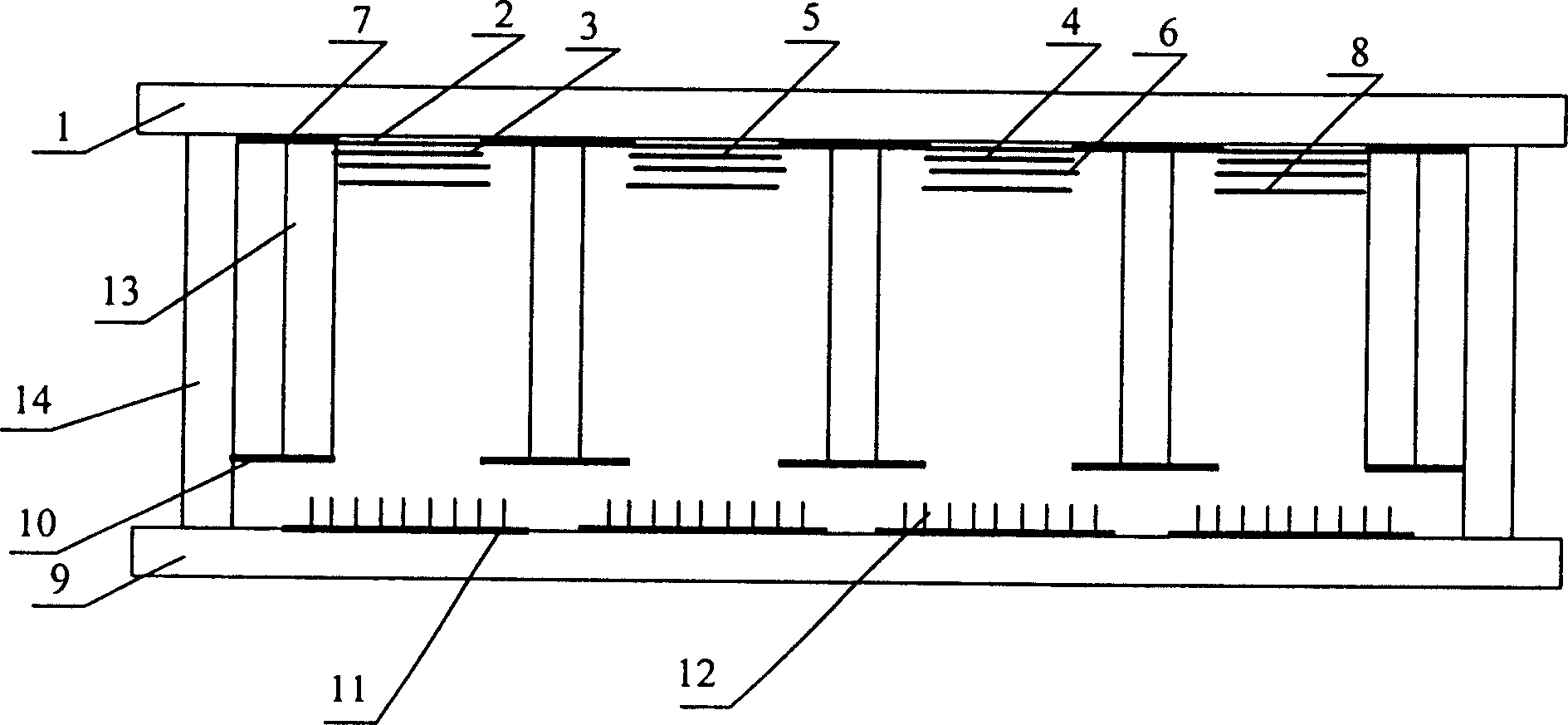

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

[0033] The anode panel in the present invention uses flat glass as the substrate material, and the flat glass in the anode panel is not only used as the substrate material of the anode of the display, but also as the outer shell packaging glass of the vacuum chamber of the overall display;

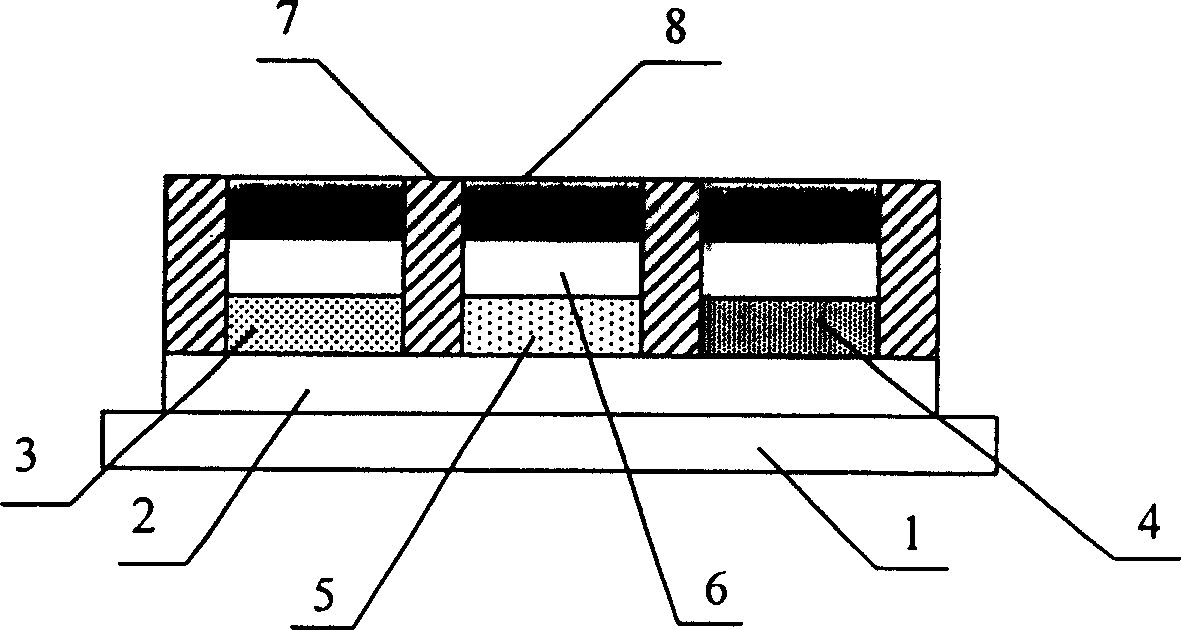

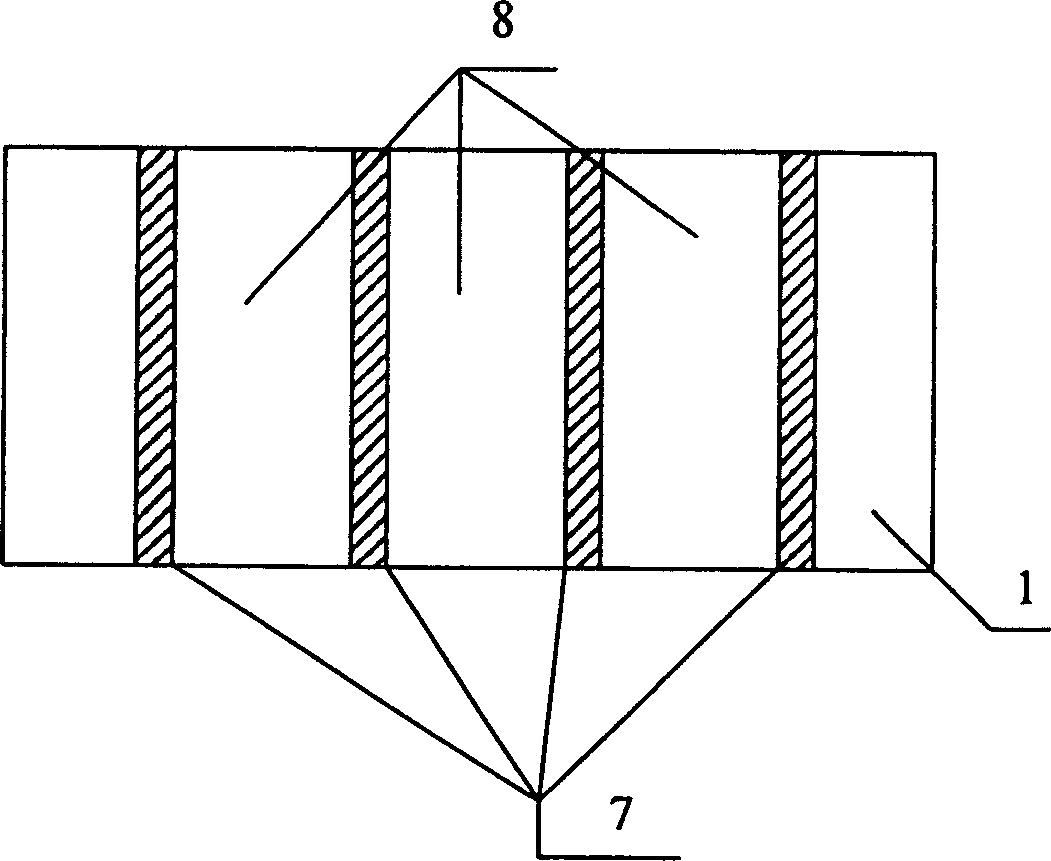

[0034] The structure of the anode panel in the present invention is composed of an anode substrate material plate glass 1, a barrier layer 2, a red filter layer 3, a blue filter layer 4, a green filter layer 5, an anode conductive strip 6, and an anode cover layer 7. .

[0035] The present invention adopts the combination method of tin indium oxide thin film, color filter layer and barrier layer to make the anode panel structure, and its manufacturing process is as follows:

[0036] 1) Scribing of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com