Three-electrode field transmitting displaying device with glass strip array as separated pole and production thereof

A technology of glass strips and spacers, applied in cathode ray/electron beam tube casing/container, image/graphic display tube, cathode ray tube/electron beam tube, etc. Problems such as device manufacturing cost and isolation column structure manufacturing process are complicated, so as to avoid the difference in thermal expansion coefficient, the manufacturing process is stable and reliable, and the manufacturing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

[0046] 1. Fabrication of the isolation column element structure

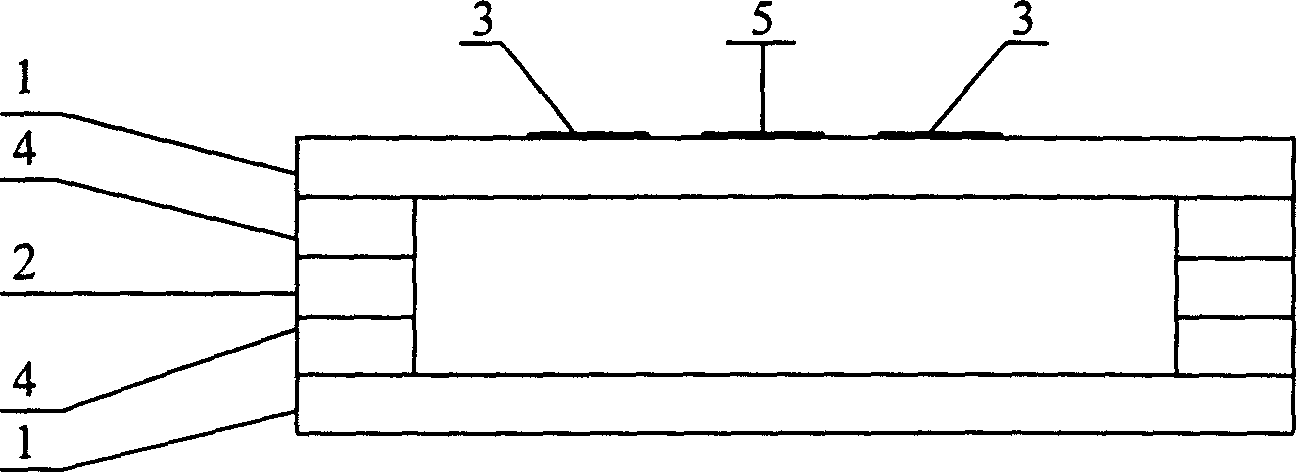

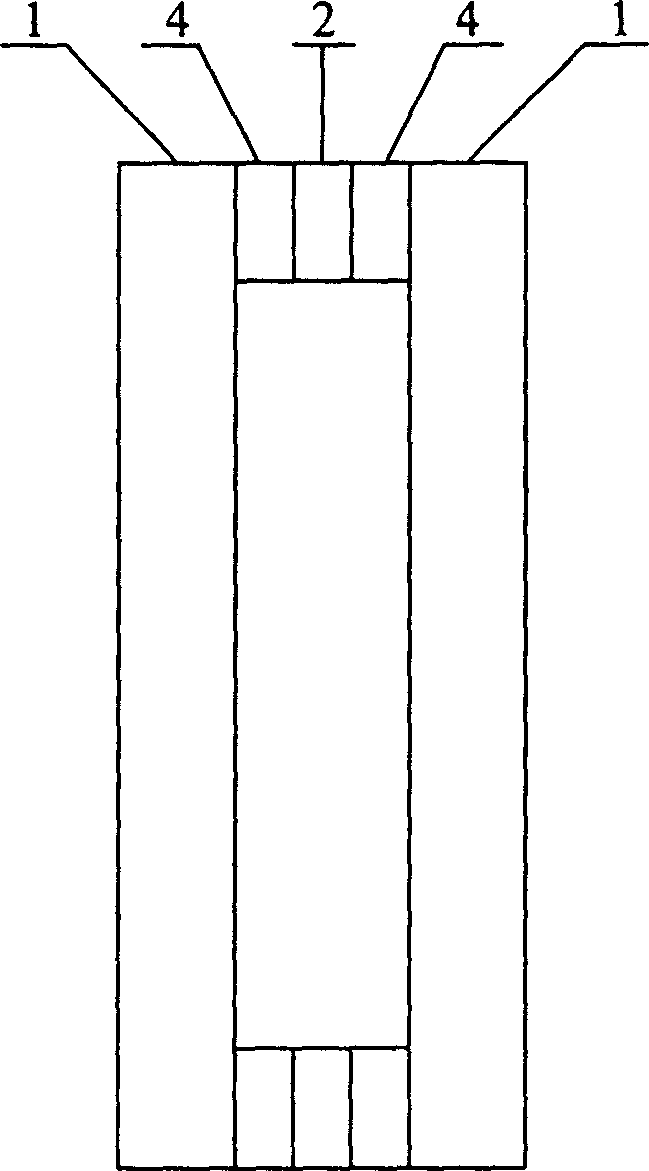

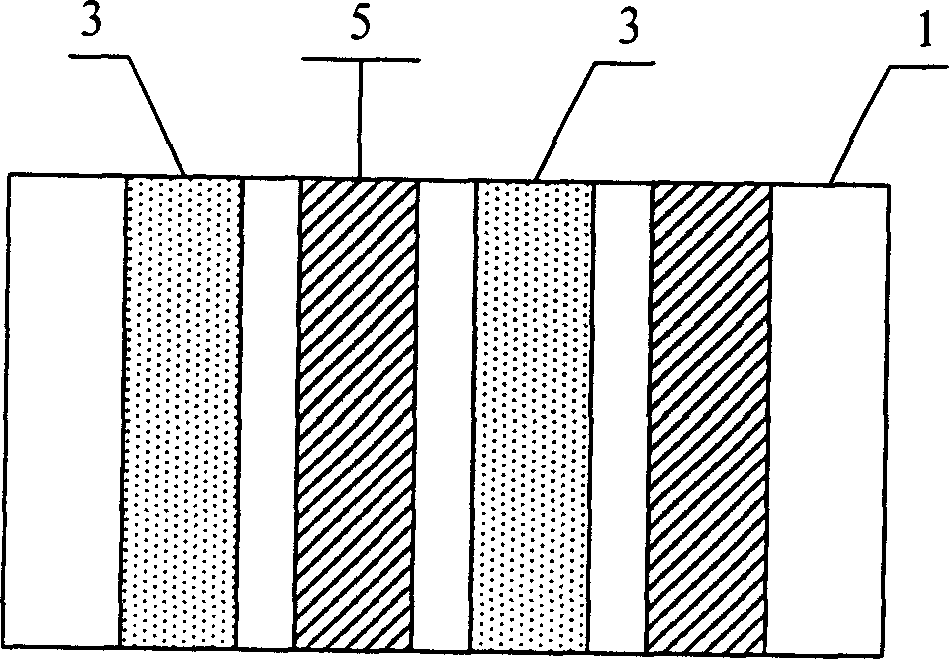

[0047] exist figure 1 , figure 2 and image 3 Among them, the structure of the isolation column element of the present invention is composed of a glass strip 1 as a base material, a mica sheet 2 as an insulating spacer, an insulating paste layer 3 , a fixed point 4 for insulating paste, and a micro-conductive substance 5 .

[0048]The spacer element structure of the present invention is made according to the following process:

[0049] 1) Scribing of substrate material glass 1:

[0050] Scribe the overall glass substrate material to form the required shape;

[0051] 2) The making of insulating slurry layer 3:

[0052] Using the screen printing process, print out the insulating paste layer of the required shape between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com