Method for manufacturing automobile welcome pedal

A technology of welcome pedals and production methods, which are applied in the arrangement of pedals or ladders, vehicle parts, and devices for applying liquid to surfaces, etc., can solve the problem of inaccurate alignment of the edge positions of metal parts and plastic parts, and affect the appearance of the product circumference. The problem of low image and structural stability, to achieve the effect of beautiful and fashionable appearance, reducing the risk of easy cracking, and fast and convenient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

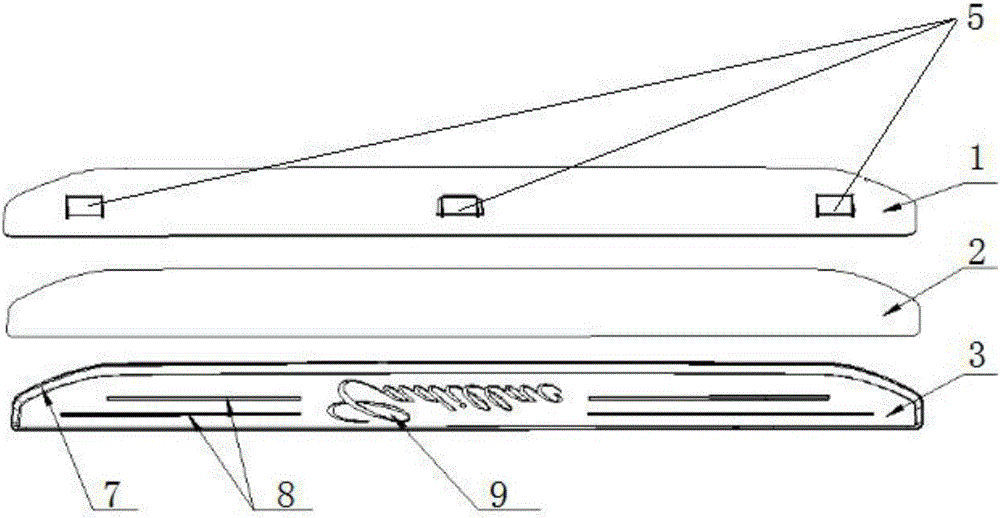

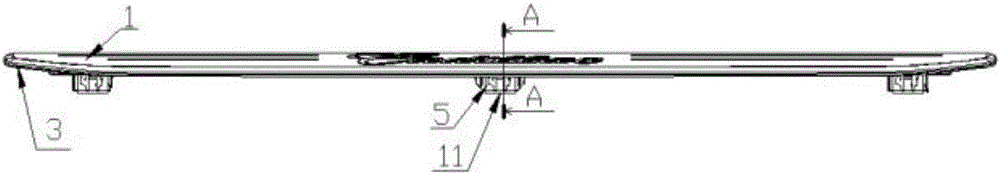

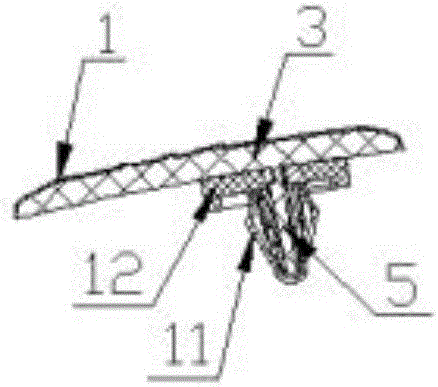

[0027] see Figure 1 to Figure 3 The invention relates to a production method of an automobile welcome pedal, which includes four processes of stamping, spraying, insert injection molding and adding accessories.

[0028] Concrete steps of the present invention are as follows:

[0029] 1) Stamping, selecting aluminum foil and performing precision stamping on it to form an aluminum substrate 3 with raised characters 9 and raised lines 8 and peripheral flanging 7 on the surface;

[0030] 2) Spraying, spraying the polymer heat-sensitive adhesive on the inner surface of the aluminum substrate 3, and baking in an oven at 90-100°C for 7-10 minutes to form the polymer heat-sensitive adhesive layer 2;

[0031] 3) Insert injection molding, put the aluminum substrate 3 coated with polymer heat-sensitive adhesive on the inner surface into the cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com