Three pole flat plate display produced by photoetching and aluminium film plating method and its producing process

A flat-panel display and aluminized film technology, applied in the direction of image/graphic display tube, cold cathode manufacturing, tube/lamp screen manufacturing, etc., can solve the problem of increasing device manufacturing cost, reducing the success rate of device manufacturing, increasing the overall device manufacturing cost, etc. problems, to achieve the requirements of reducing process and equipment precision, avoid shortening the service life of devices, and improve the production success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the drawings and embodiments, but the present invention is not limited to these embodiments.

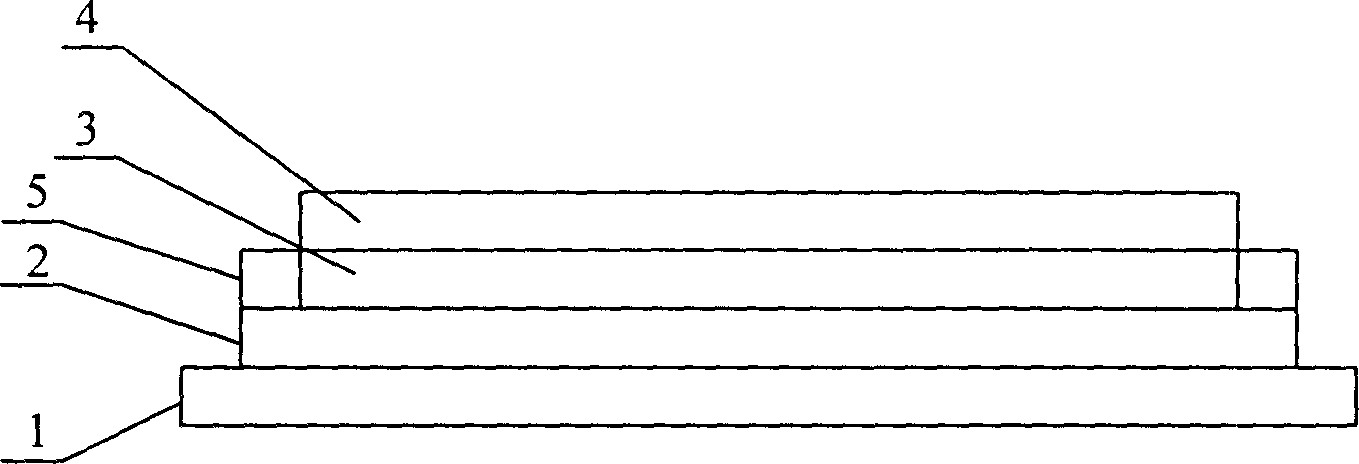

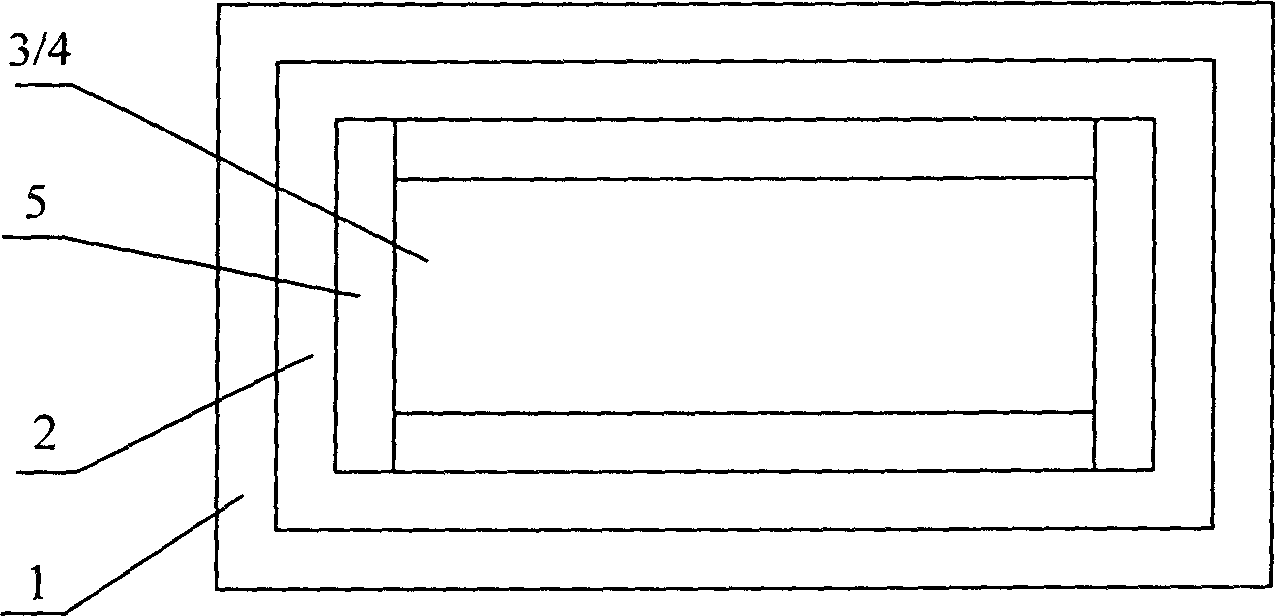

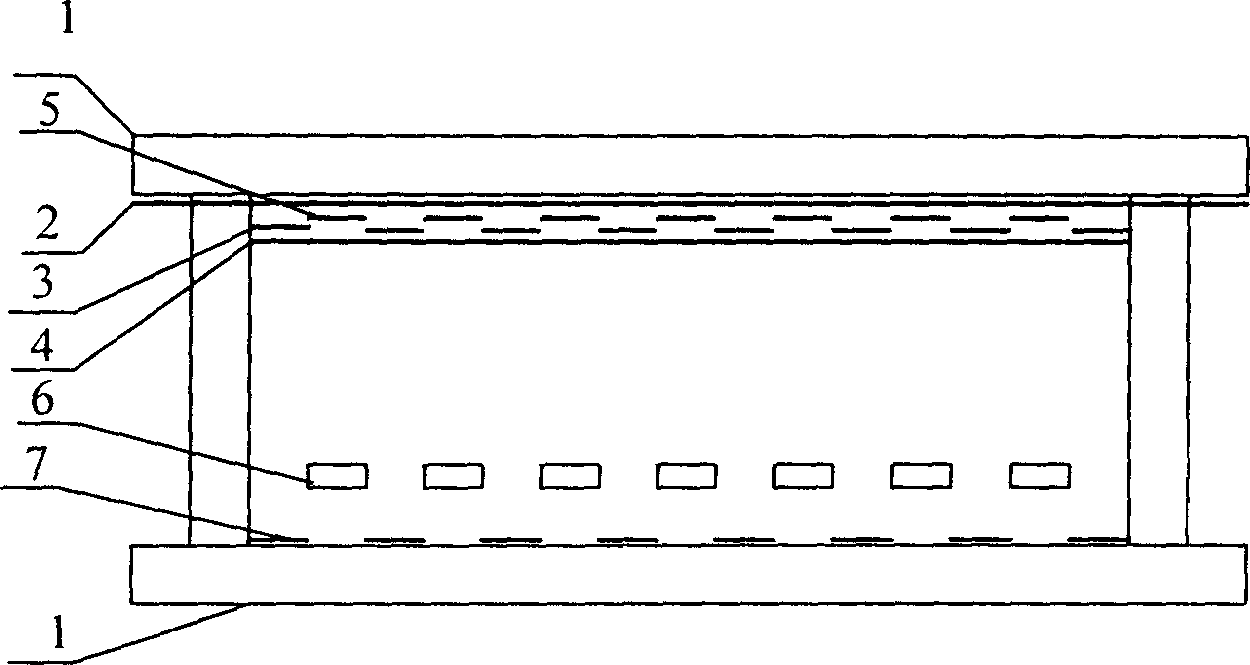

[0039]The anode panel in the present invention uses flat glass as the substrate material, and the flat glass in the anode panel is used as the substrate material for the anode of the display, and at the same time as the packaging glass of the overall display vacuum chamber; the flat panel in the anode panel of the present invention There is a tin indium oxide thin film layer inside the glass; the tin indium oxide thin film layer in the anode panel of the present invention can be realized by photolithography and other processes to achieve the required circuit pattern; the tin in the anode panel of the present invention Indium oxide patterns are isolated from each other by insulating paste; the insulating paste layer in the anode panel of the present invention is cured by a conventional high-temperature sinterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com