Construction method for beam-making platform and construction method for box beam prefabricated factory

A technology for beam-making pedestals and construction methods, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of uneven surface of beam-making pedestals, substandard quality, and poor precision of box girders, etc., and achieves strong practicability, Avoid uneven settlement and ensure the quality of beam making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

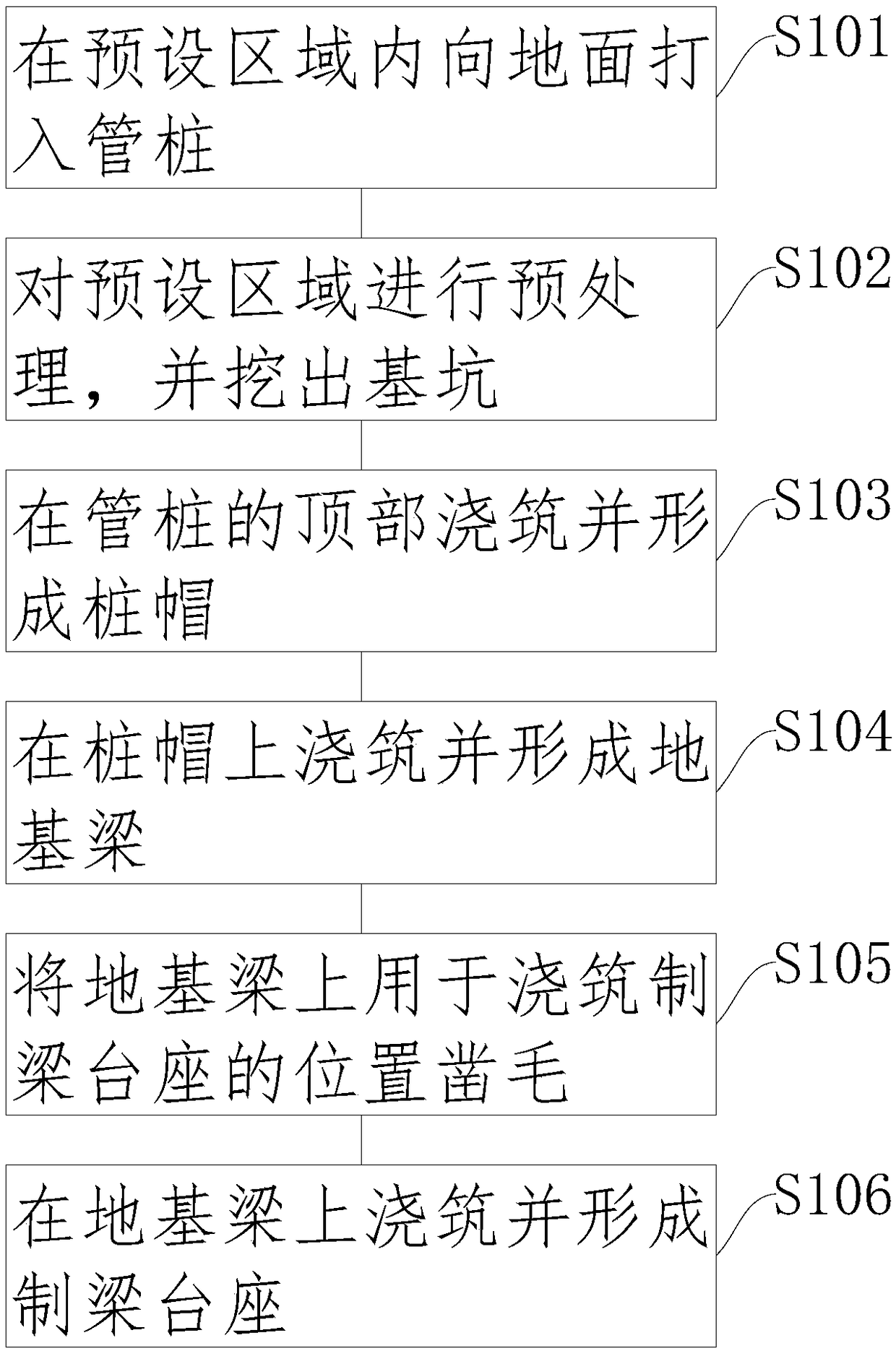

[0031] Please refer to figure 1 , An embodiment of the present invention provides a construction method for a beam-making pedestal, which is used for manufacturing a beam-making pedestal. It can manufacture stable and reliable beam-making pedestals that avoid uneven settlement, so as to ensure the quality of beam-making, strong practicability, safety and efficiency. In this embodiment, the beam-making platform is used to make the box girder, the installation of formwork and steel bars, concrete pouring and curing of the beam body, and all construction procedures from pre-tensioning to beam body moving away from the platform are all completed on the beam-making platform. Beam-making pedestal is an important facility to ensure the quality of beam-making.

[0032] The construction method of the beam-making pedestal comprises the following steps:

[0033] Step S101: Driving pipe piles into the ground within a preset area.

[0034] It should be noted that the pipe piles are used...

no. 2 example

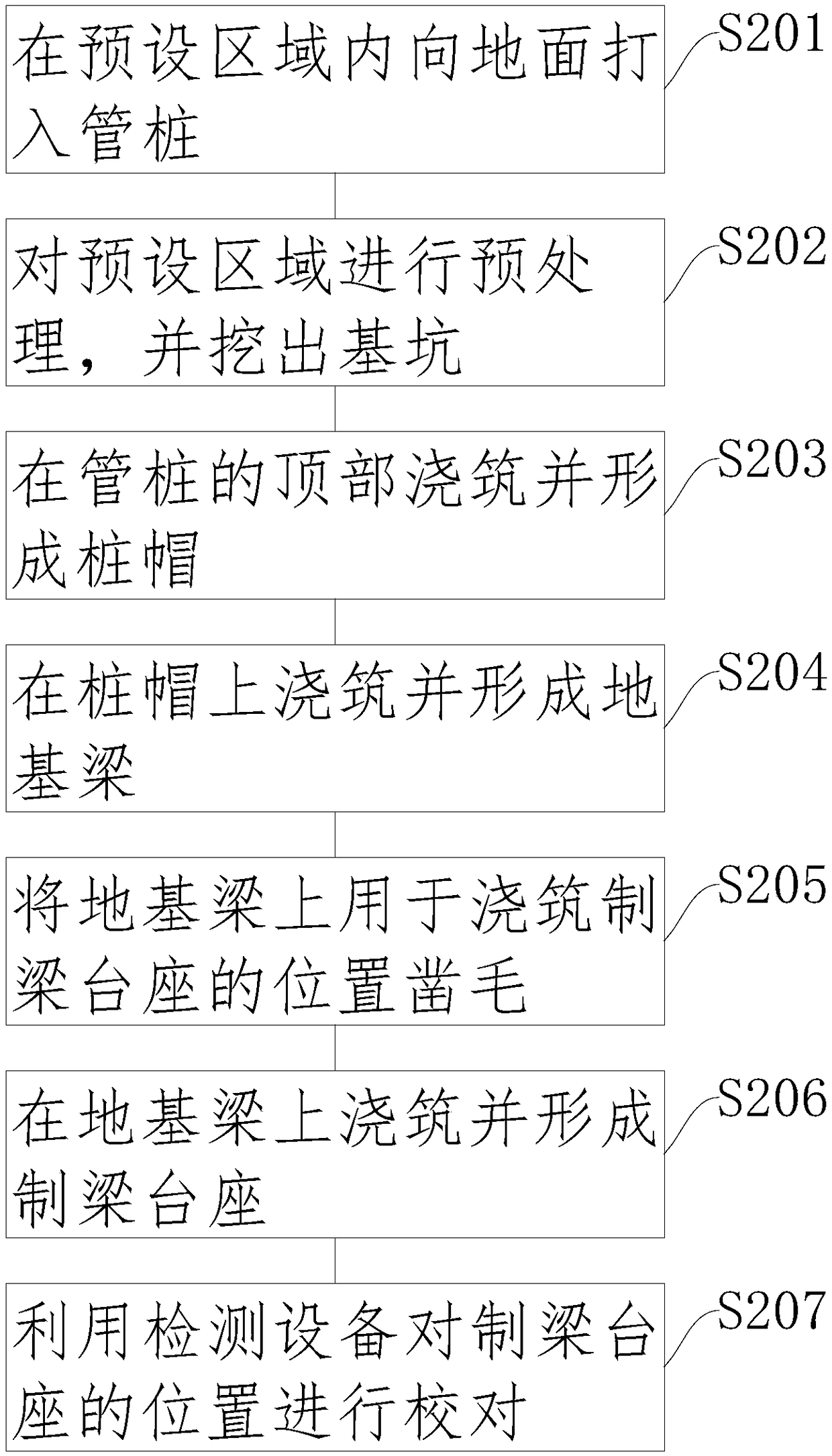

[0072] An embodiment of the present invention provides a construction method for a box girder prefabrication yard, which is used for constructing a box girder prefabrication yard.

[0073] The construction methods of the box girder precast yard include:

[0074] Step S201: Driving pipe piles into the ground within a preset area.

[0075] Step S202: Perform preprocessing on the preset area, and excavate the foundation pit.

[0076] Step S203: pouring and forming a pile cap on the top of the pipe pile.

[0077] Step S204: pouring and forming foundation beams on the pile cap.

[0078] Step S205: Chisel rough the position on the foundation beam used for pouring the beam-making pedestal.

[0079] Step S206: pouring on the foundation beam and forming a beam-making platform.

[0080] Step S207: Proofread the position of the beam-making pedestal by using the detection equipment.

[0081] The beneficial effect of the construction method for the box girder precast yard provided by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com