A kind of low voc organosilicon sealant and preparation method thereof

A silicone and sealant technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of large usage of adhesion promoters and coupling agents, affecting the stability of electronic products, and VOC content High-level problems, to achieve stable product quality, faster curing and cross-linking, and lower VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

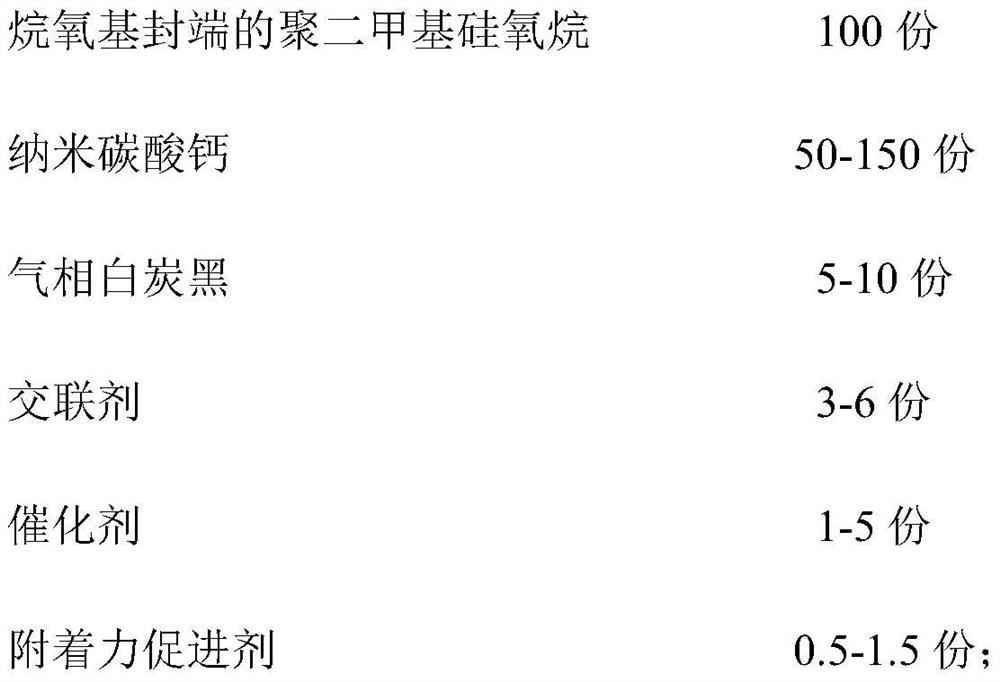

Method used

Image

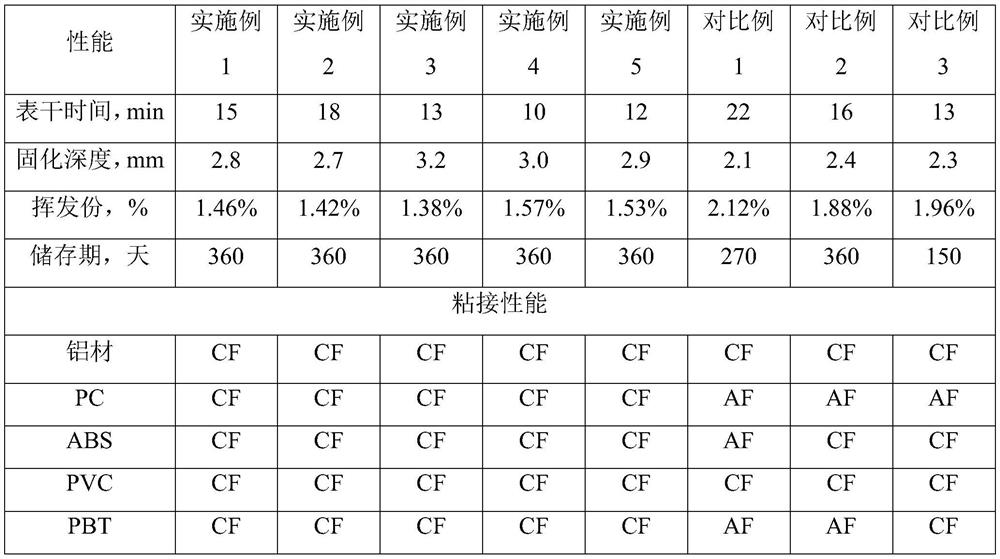

Examples

Embodiment 1

[0043] The preparation method of the low VOC silicone sealant of the present embodiment is as follows:

[0044] (1) 100 parts by mass of alkoxy-terminated polydimethylsiloxane (kinematic viscosity at 25° C. is 20 Pa s) with a structure such as formula (3), 80 parts by mass of nano-calcium carbonate with an average particle diameter of 50 nm , and 5 parts by mass of BET specific surface area is 120m 2 / g of fumed silica was added into a vacuum kneader, under the condition of nitrogen protection, dehydration, blending and kneading at 125°C for 120min, and then cooled to obtain the base material;

[0045] (CH 3 )(CH 3 O) 2 SiO-[(CH 3 ) 2 SiO] 1000 -Si(OCH 3 ) 2 (CH 3 ) (3)

[0046] (2) at room temperature, the base material obtained in the above step (1), 6 parts by mass of methyltrimethoxysilane crosslinking agent, the citrate chelate catalyst of 2 parts by mass of isopropyl titanate, and 0.75 parts by mass of a polyfunctional silane coupling agent with the structure ...

Embodiment 2

[0050] The preparation method of the low VOC silicone sealant of the present embodiment is as follows:

[0051] (1) 100 parts by mass of alkoxy-terminated polydimethylsiloxane (kinematic viscosity at 25°C is 50 Pa s) with a structure such as formula (5), 50 parts by mass of nano-calcium carbonate with an average particle diameter of 20 nm , and 10 parts by mass of BET specific surface area is 200m 2 / g of fumed silica was added into the vacuum kneader, under the condition of nitrogen protection, dehydration, blending and kneading at 130°C for 180min, and then cooled to obtain the base material;

[0052] (CH 2 =CH)(CH 3 O) 2 SiO-[(CH 3 ) 2 SiO] 1500 -Si(OCH 3 ) 2 (CH=CH 2 ) (5);

[0053] (2) At room temperature, the base material obtained in the above step (1), a mixed crosslinking agent composed of 3 parts by mass of propyltrimethoxysilane and 1 part by mass of methyltrimethoxysilane, and 1 part by mass of titanic acid Isopropyl ester catalyst, and 0.5 mass parts of...

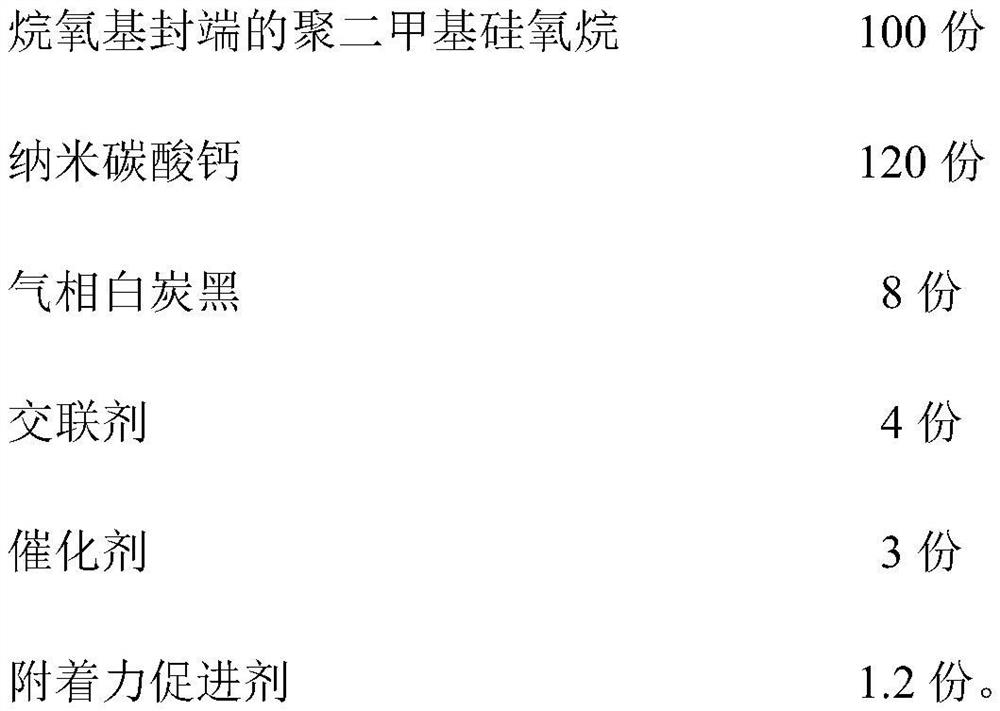

Embodiment 3

[0057] The preparation method of the low VOC silicone sealant of the present embodiment is as follows:

[0058] (1) 80 parts by mass of alkoxy-terminated polydimethylsiloxane (kinematic viscosity at 25°C is 20 Pa·s), 20 parts by mass of alkoxy-terminated polydimethylsiloxane with the structure of formula (7) Group-terminated polydimethylsiloxane (kinematic viscosity at 25°C is 80 Pa s), 120 parts by mass of nano-calcium carbonate with an average particle size of 30 nm, and 8 parts by mass of BET with a specific surface area of 180 m 2 / g of fumed silica was added into the vacuum kneader, under the condition of nitrogen protection, dehydration, blending and kneading at 120°C for 150min, and then cooled to obtain the base material;

[0059] (CH 3 )(CH 3 O) 2 SiO-[(CH 3 ) 2 SiO] 1000 -Si(OCH 3 ) 2 (CH 3 ) (3);

[0060] (CH 3 )(CH 3 O) 2 SiO-[(CH 3 ) 2 SiO] 2000 -Si(OCH 3 ) 2 (CH 3 ) (7);

[0061] (2) At room temperature, the base material obtained in the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com