Flue gas waste heat recovery system with heat pump and gas-water surface type heat exchanger coupled

A recovery system and flue gas waste heat technology, applied in heat pumps, lighting and heating equipment, refrigerators, etc., can solve problems such as water vapor environmental pollution, flue gas temperature rise, boiler efficiency reduction, etc., to achieve energy saving and energy saving efficiency The effect of optimization and energy-saving efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

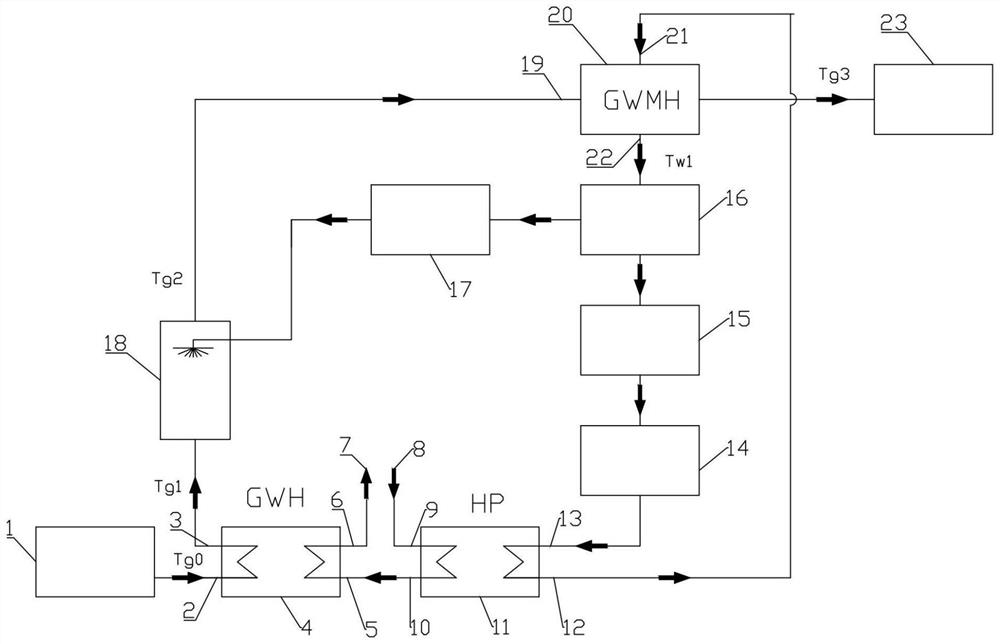

[0038] like figure 2 As shown in the figure, a flue gas waste heat recovery system coupled with a heat pump and an air-to-water surface heat exchanger includes a boiler waste heat recovery system and a heat user heating system; the boiler waste heat recovery system also includes a tail flue 1 connected to the furnace. , the air-water surface heat exchanger 4 connected to the tail flue 1, the desulfurization tower 18 connected to the air-to-water surface heat exchanger 4, the air-water mixing heat exchanger 20 connected to the desulfurization tower 18, and the The water circulation system connected with the water mixing heat exchanger 20; the heat user heating system is connected with the air-water surface heat exchanger 4 and the water circulation system at the same time.

[0039] Furnace: refers to the equipment that can generate flue gas, and the equipment can be boilers, kilns, smelting furnaces, gas engines, etc., and mainly refers to coal-fired boilers in this embodiment...

Embodiment 2

[0057] The specific process is:

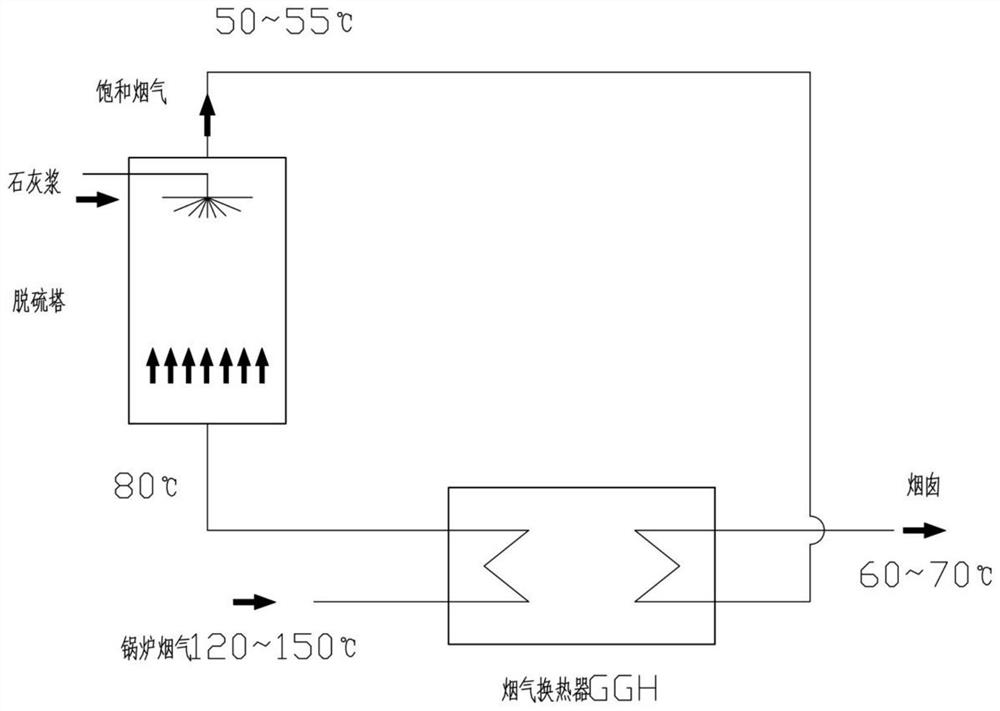

[0058] The tail flue gas of the boiler or other coal-fired and gas-fired furnaces enters the air-water surface heat exchanger through the tail flue, and is cooled by heat exchange, and the flue gas temperature is changed by T g0 down to T g1 , and then enter the desulfurization tower. In general, the boiler tail flue gas temperature T g0 is about 120°C. If it directly enters the desulfurization tower, the temperature of the desulfurization tower will rise, and the discharge temperature will reach above 60 °C, which consumes a lot of water and heat, and causes pollution such as haze in the environment. If the temperature of the flue gas at 120°C drops to 80°C through the air-water surface heat exchanger, and then enters the desulfurization tower, the temperature of the flue gas from the desulfurization tower is about 50-52°C, and the water vapor and water consumption are greatly reduced.

[0059] In the background art, wet desulfurization c...

Embodiment 3

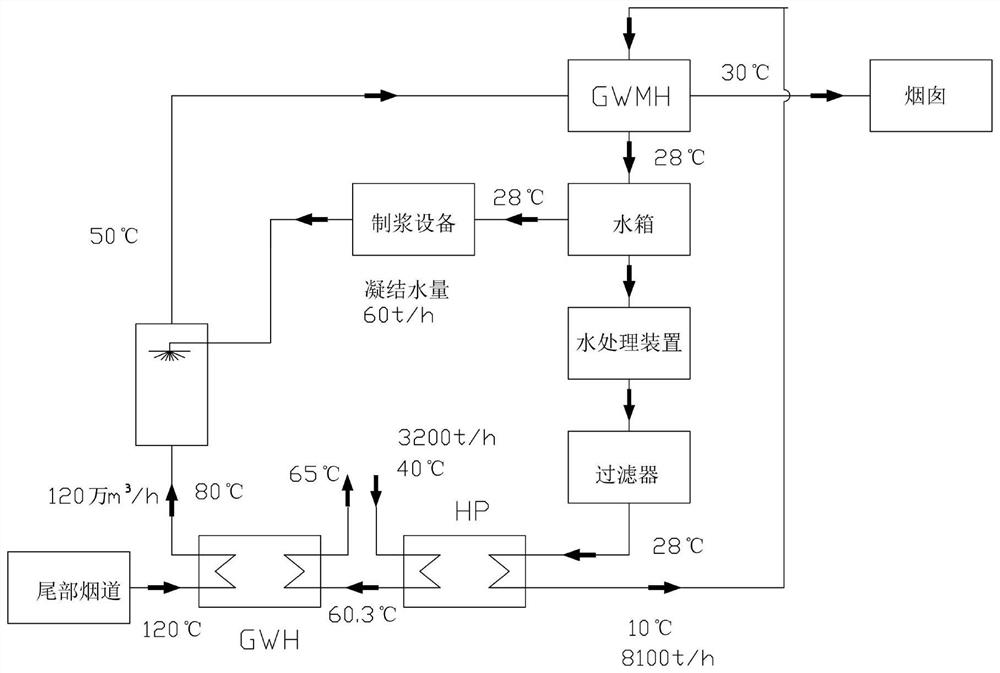

[0070] This embodiment is a practical application scheme of Embodiment 1.

[0071] A large coal-fired thermal power plant recovers the waste heat from wet desulfurization flue gas for heat supply. The basic parameters of the power plant are as follows:

[0072] Power plant power generation: 350MW;

[0073] Flue gas flow after desulfurization: 1.2 million m 3 / h;

[0074] Flue gas water vapor content: 15%;

[0075] Heating temperature: 60℃;

[0076] Heating and return water temperature: 38 to 45 °C (take the design value of 40 °C);

[0077] The circulating water volume of the heating network: ∠4000t / h.

[0078] The system of the present application is used to recover the waste heat of the flue gas, wherein the gas-water mixing heat exchanger adopts a spray tower for heat generation. The simplified thermal system diagram is shown in image 3 , and label the temperature of each node:

[0079] According to the above parameters, the relevant data are calculated as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com