Exhaust gas treatment method, and exhaust gas treatment device

A technology for waste gas treatment and waste gas, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as difficulty in use, and achieve the effects of reducing water vapor, easy maintenance, and simplifying waste gas treatment devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

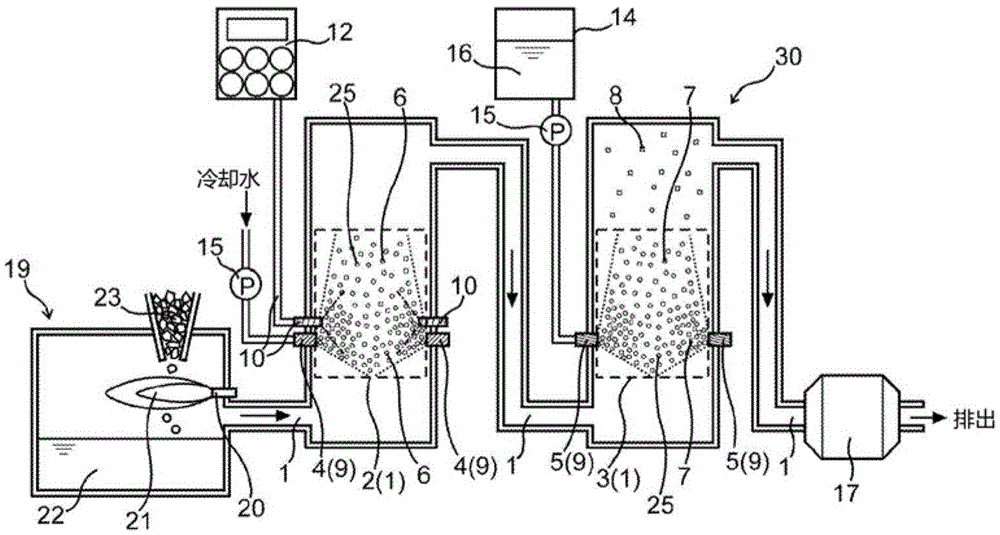

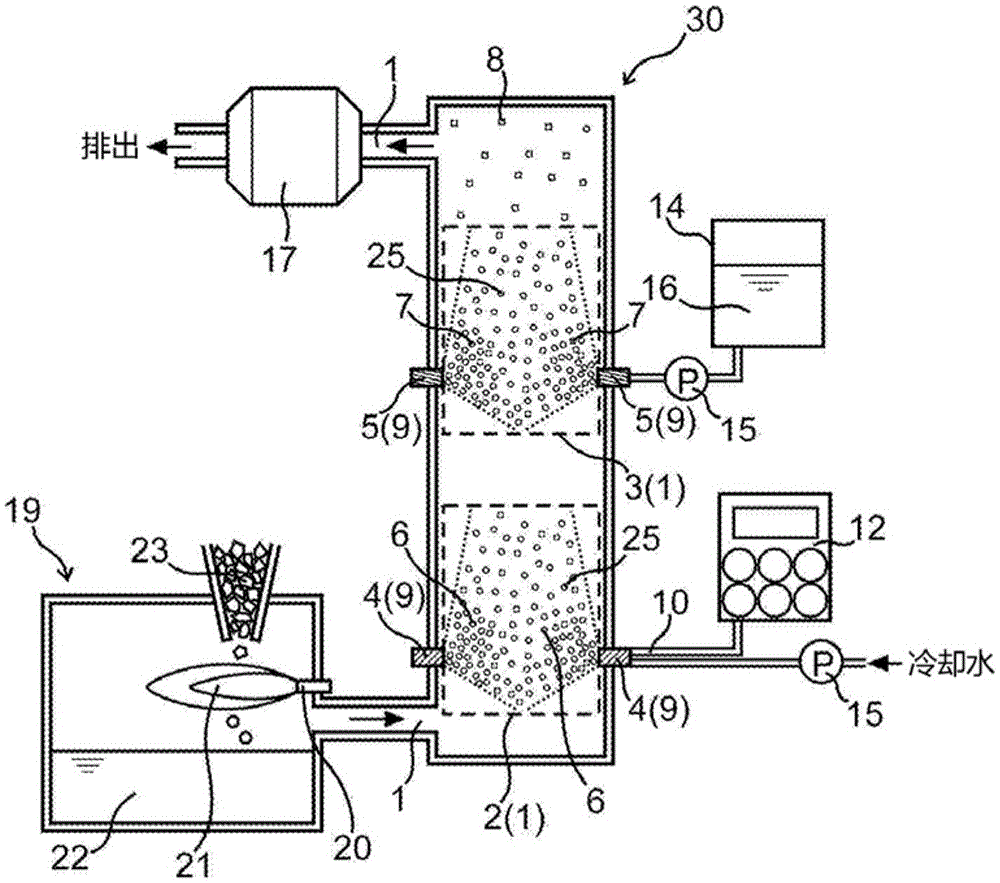

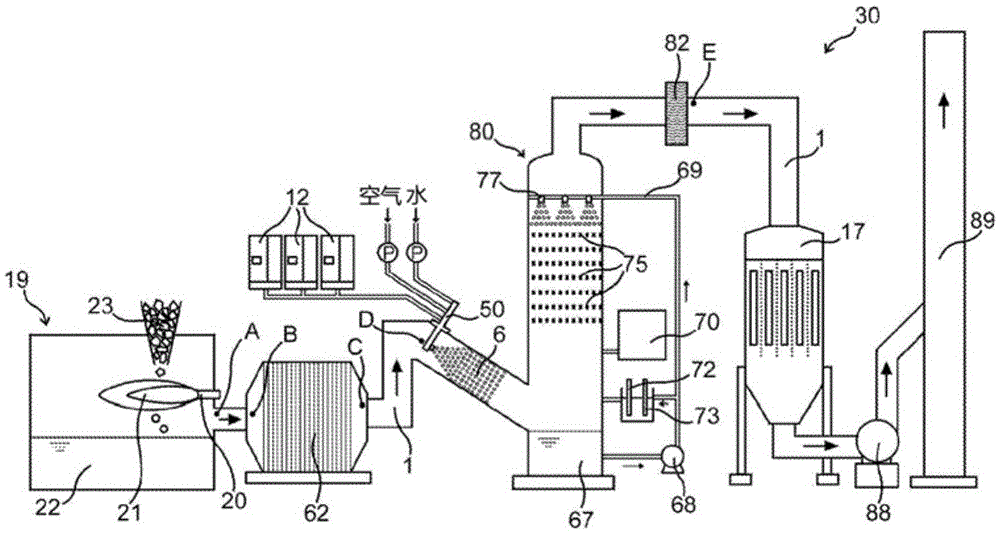

[0036] The exhaust gas treatment method of the present invention is characterized in that the method includes the following steps: x Water or an aqueous solution and ozone as the first liquid are supplied to the waste gas at a temperature above 150° C. to generate a first mist in which water droplets of the first liquid float in the waste gas containing ozone gas.

[0037] In the present invention, mist refers to a gas in which many water droplets float. Therefore, the mist includes a plurality of water droplets floating (liquid phase) and a gas (gas phase) around the water droplets.

[0038] In the exhaust gas treatment method of the present invention, preferably, the first mist is generated by spraying the first liquid in the exhaust gas, and ozone gas is supplied to the generated first mist.

[0039] According to such a structure, the 1st mist in which the water droplet of the 1st liquid floats can be generated in the exhaust gas containing ozone gas. In addition, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com