Heatproof PVC composite material used for baby bath and production method thereof

A technology for baby bathtubs and composite materials, which is applied in the field of heat-resistant PVC composite materials for baby bathtubs and its preparation, and can solve the problems of PVC heat resistance, poor thermal stability, general PVC wear resistance, low chemical stability, etc. problems, achieve excellent heat insulation performance, reduce friction coefficient, and improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

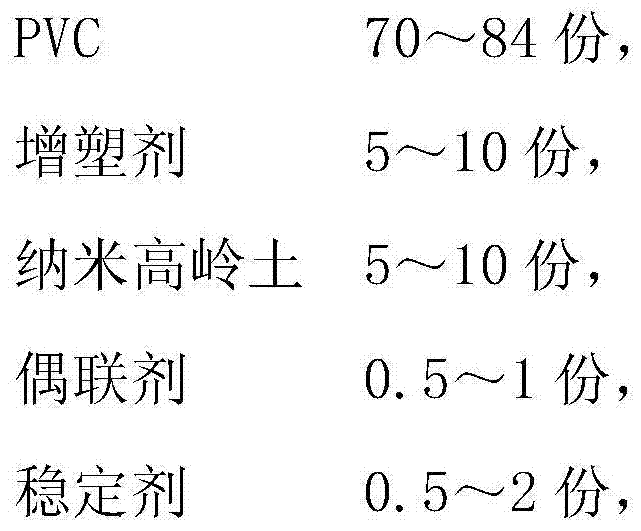

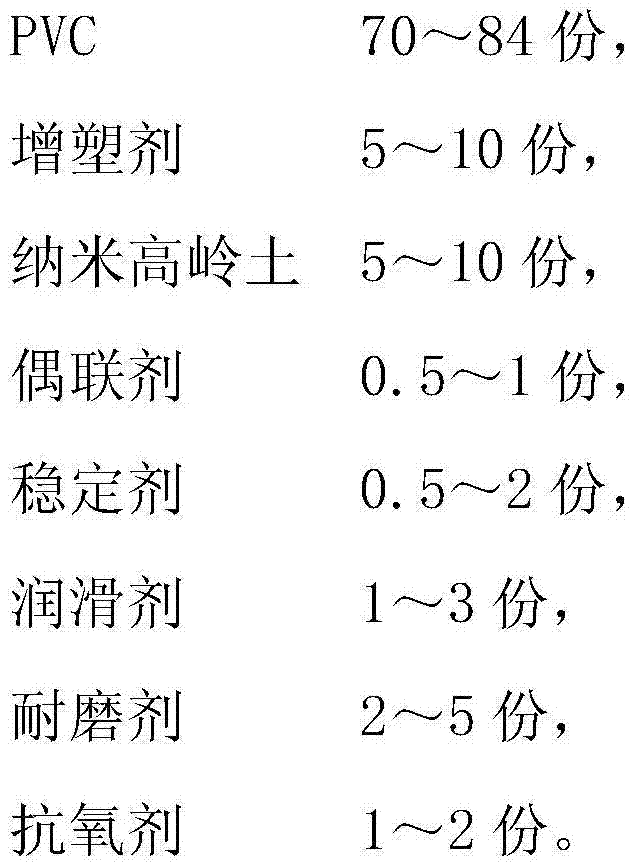

Method used

Image

Examples

Embodiment 1

[0025] A PVC composite material for a heat-resistant baby bathtub, which consists of 70 parts by weight of PVC, 10 parts of tributyl citrate, 7 parts of nano-kaolin, 1 part of epoxy silane coupling agent, and 2 parts of calcium stearate. 1, 3 parts of PE wax, 5 parts of molybdenum disulfide, 2 parts of antioxidant 1010.

[0026] Its preparation method comprises the following steps:

[0027] (1) Add epoxy silane coupling agent to ethanol solution and hydrolyze to clarification to obtain the hydrolyzate of epoxy silane coupling agent, add nano-kaolin to the hydrolyzate of epoxy silane coupling agent, react after 1 hour , suction filtration, drying, and crushing to obtain modified nano kaolin;

[0028] (2) Put the modified nano-kaolin obtained in step (1) and other components into a mixer together and stir for 45 minutes at 110° C. to obtain a mixture;

[0029] (3) Add the mixture obtained in step (2) into a twin-screw extruder to extrude and granulate. The temperature of the e...

Embodiment 2

[0031] A PVC composite material for a heat-resistant baby bathtub, which consists of 84 parts by weight of PVC, 5 parts of tributyl citrate, 6 parts of nano-kaolin, 0.5 parts of epoxy silane coupling agent, and 0.5 parts of calcium stearate 1 part, PE wax 1 part, molybdenum disulfide 2 parts, antioxidant 1010 1 part.

[0032] Its preparation method comprises the following steps:

[0033] (1) Add epoxy silane coupling agent to ethanol solution and hydrolyze to clarification to obtain the hydrolyzate of epoxy silane coupling agent, add nano-kaolin to the hydrolyzate of epoxy silane coupling agent, react after 1 hour , suction filtration, drying, and crushing to obtain modified nano kaolin;

[0034] (2) Put the modified nano-kaolin obtained in step (1) and other components into a mixer together and stir for 45 minutes at 110° C. to obtain a mixture;

[0035] (3) Add the mixture obtained in step (2) into a twin-screw extruder to extrude and granulate. The temperature of the extr...

Embodiment 3

[0037] A PVC composite material for a heat-resistant baby bathtub, which consists of 74 parts by weight of PVC, 6 parts of tributyl citrate, 1 part of nano-kaolin, 0.6 parts of epoxy silane coupling agent, and 1.4 parts of calcium stearate. 2.5 parts of PE wax, 4 parts of molybdenum disulfide, 1.5 parts of antioxidant 1010.

[0038] Its preparation method comprises the following steps:

[0039] (1) Add epoxy silane coupling agent to ethanol solution and hydrolyze to clarification to obtain the hydrolyzate of epoxy silane coupling agent, add nano-kaolin to the hydrolyzate of epoxy silane coupling agent, react after 1 hour , suction filtration, drying, and crushing to obtain modified nano kaolin;

[0040] (2) Put the modified nano-kaolin obtained in step (1) and other components into a mixer together and stir for 45 minutes at 110° C. to obtain a mixture;

[0041] (3) Add the mixture obtained in step (2) into a twin-screw extruder to extrude and granulate. The temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com