Parcel type heat resistant slow release ammonium carbonate and its preparation method

A wrapped type, ammonium bicarbonate technology, applied in ammonium salt fertilizer, nitrogen fertilizer, fertilizer mixture, etc., to reduce pollution, avoid burning seedlings or loss with water, and broaden the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of coating layer mixed solution: Weigh 5 parts of liquid mulch film, 5 parts of epoxy resin and 5 parts of low-temperature curing agent according to 1g each, add an appropriate amount of diluent or co-solvent, and stir evenly at room temperature to obtain the content of the coating layer material Mix solution for 15g of coating layer, set aside. In this embodiment, the epoxy resin is E52, the low-temperature curing agent is T31, and the diluent or co-solvent is chloroform.

Embodiment 2

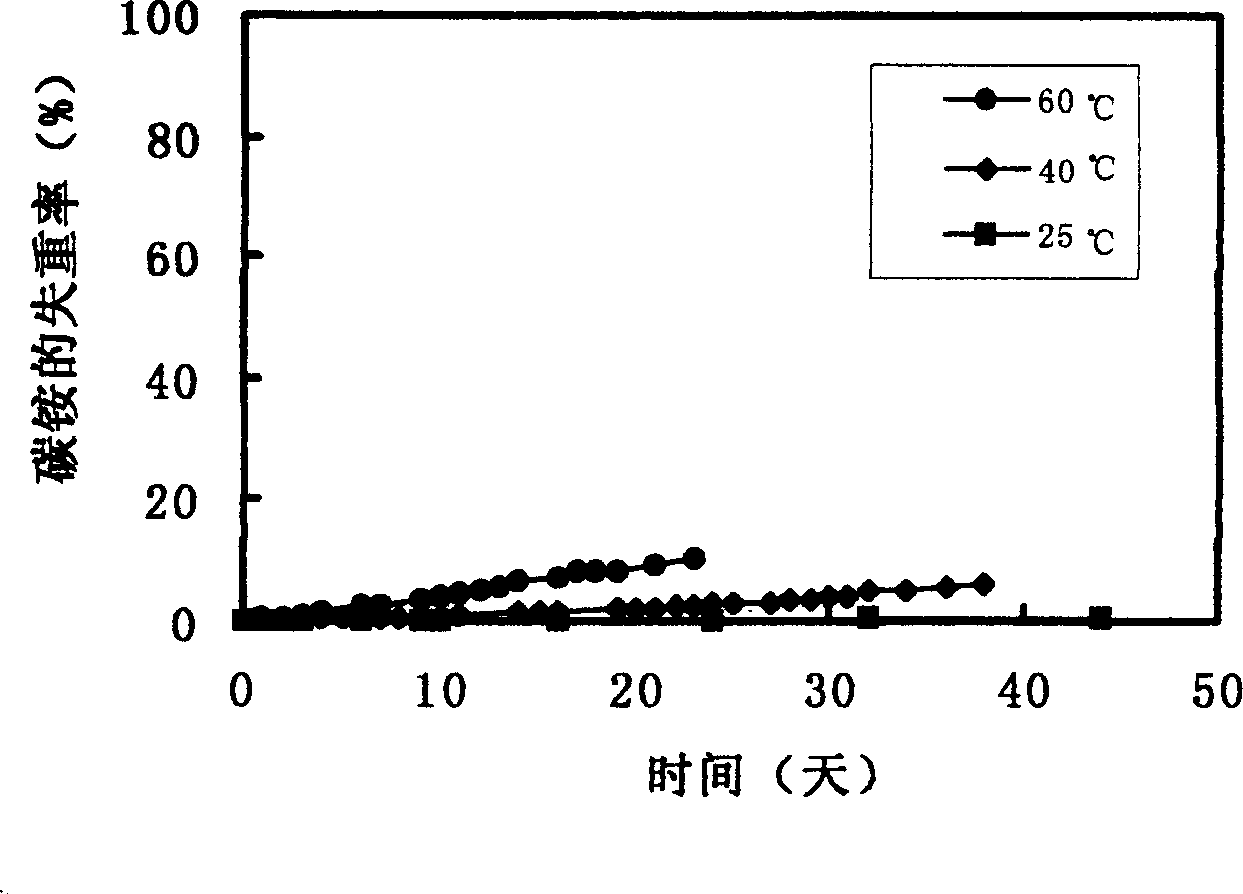

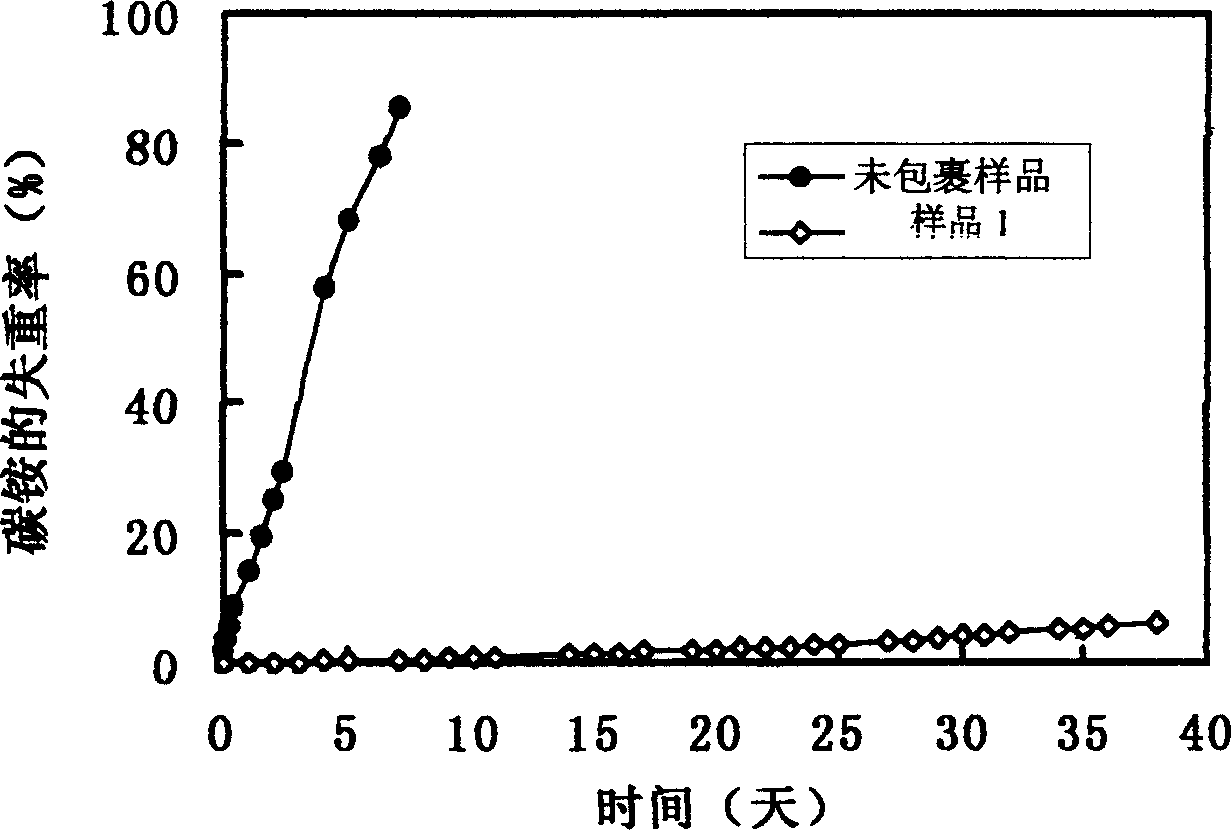

[0029] Get 85g of sheet-like ammonium bicarbonate (about 0.5 ± 0.1g each weighing about 0.5 ± 0.1g) whose geometrical dimension is 10mm * 4mm by tablet press molding, spray into the coating mixed solution prepared in Example 1 under agitation, while spraying While adding an appropriate amount of talcum powder, after spraying, dry at room temperature for 24 hours, and then place it indoors for at least 24 hours to obtain sample 1 of wrapped heat-resistant slow-release ammonium bicarbonate particles.

[0030] During specific implementation, the ammonium bicarbonate particles can also be granular or spherical or other three-dimensional geometric shapes.

Embodiment 3

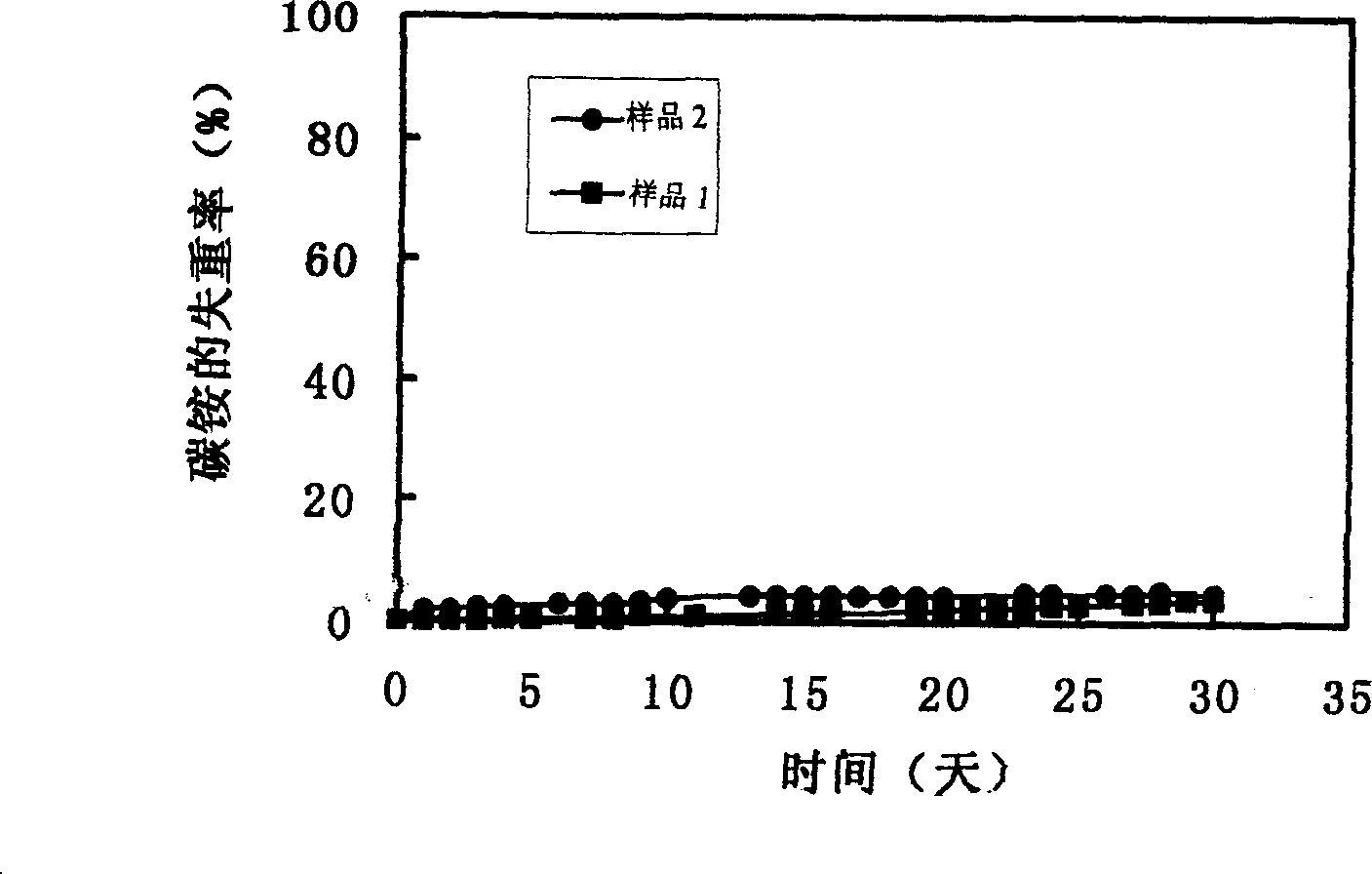

[0032] Preparation of the coating mixed solution: Weigh 4 parts of liquid mulch, 4 parts of epoxy resin and 4 parts of low-temperature curing agent according to 1g each, add an appropriate amount of diluent or co-solvent, and stir evenly at room temperature to obtain the content of the coating layer Mix solution for 12g of coating layer, set aside. In this embodiment, the epoxy resin is E52, the low-temperature curing agent is T31, and the diluent or co-solvent is chloroform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com