Solar tube and its processing method

A technology of solar energy and internal tubes, applied in the field of solar tubes and their processing, can solve problems such as high cost, increased saturated steam pressure, and difficult batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

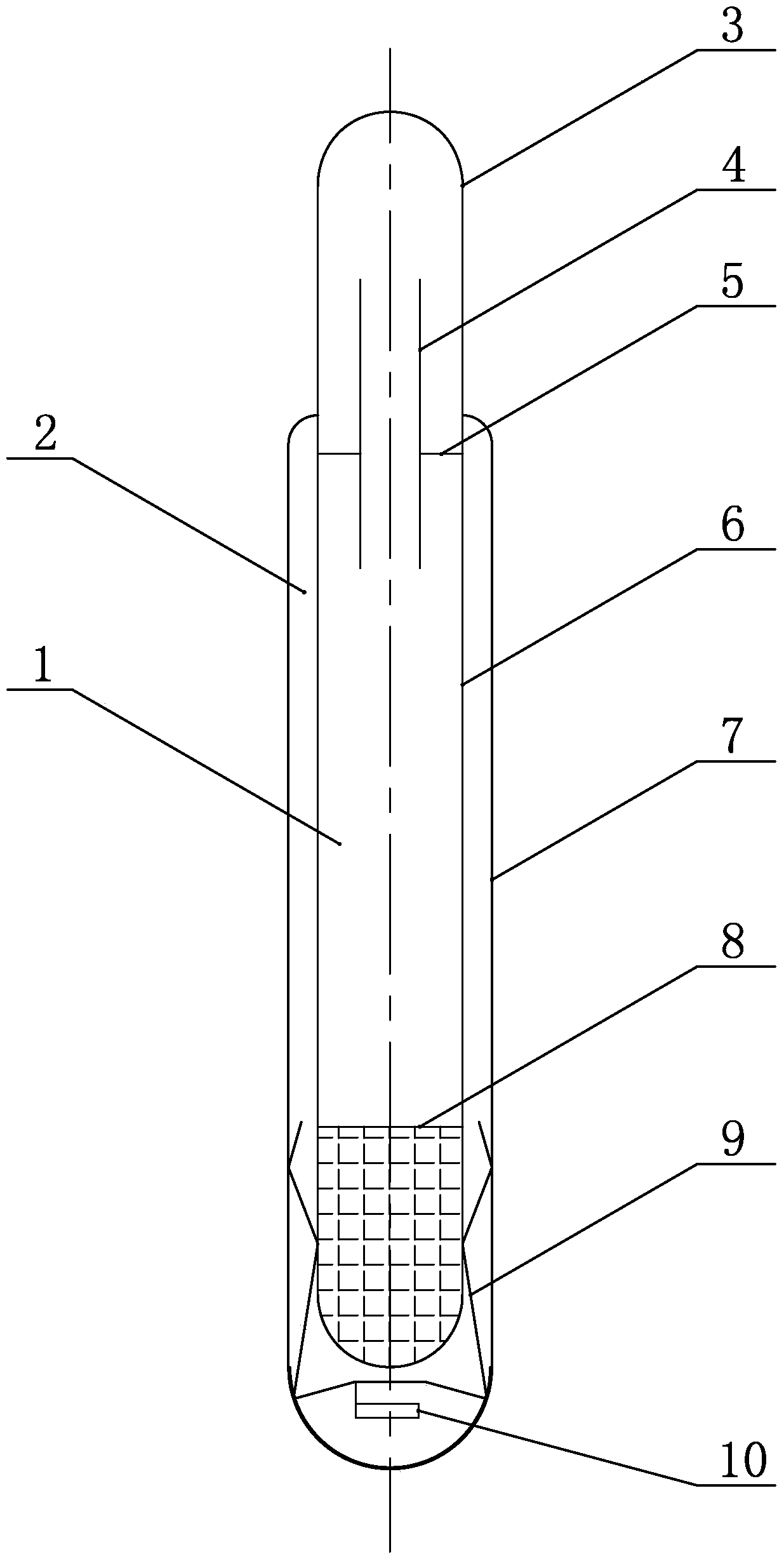

Examples

Embodiment 2

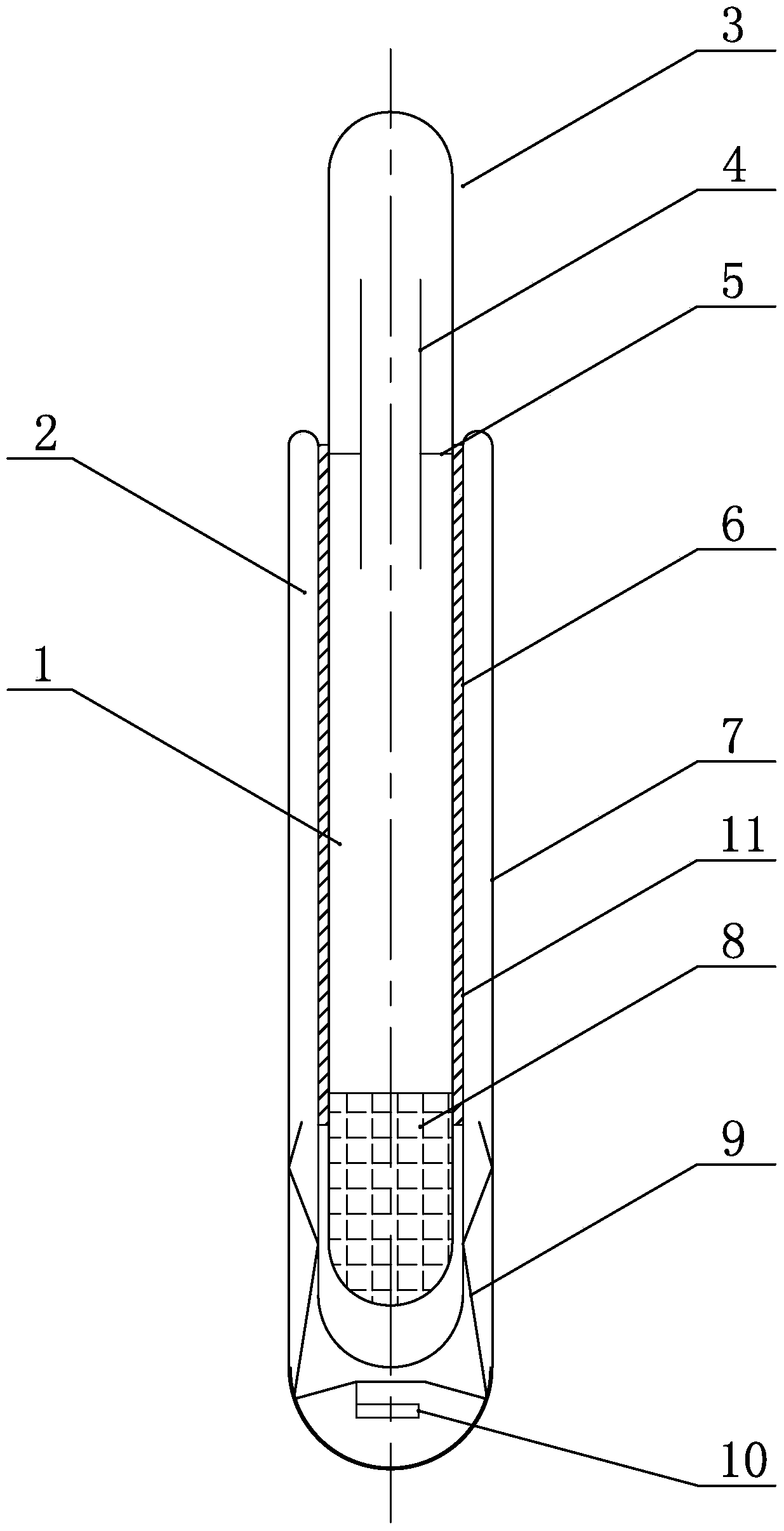

[0035] Example 2, such as figure 2As shown, the difference between this embodiment and Embodiment 1 lies in that: a heat-conducting material 11 is arranged inside the inner tube 6, and the heat-conducting material is selected from heat-conducting adhesive, heat-conducting pad or heat-conducting silicone grease.

Embodiment 3

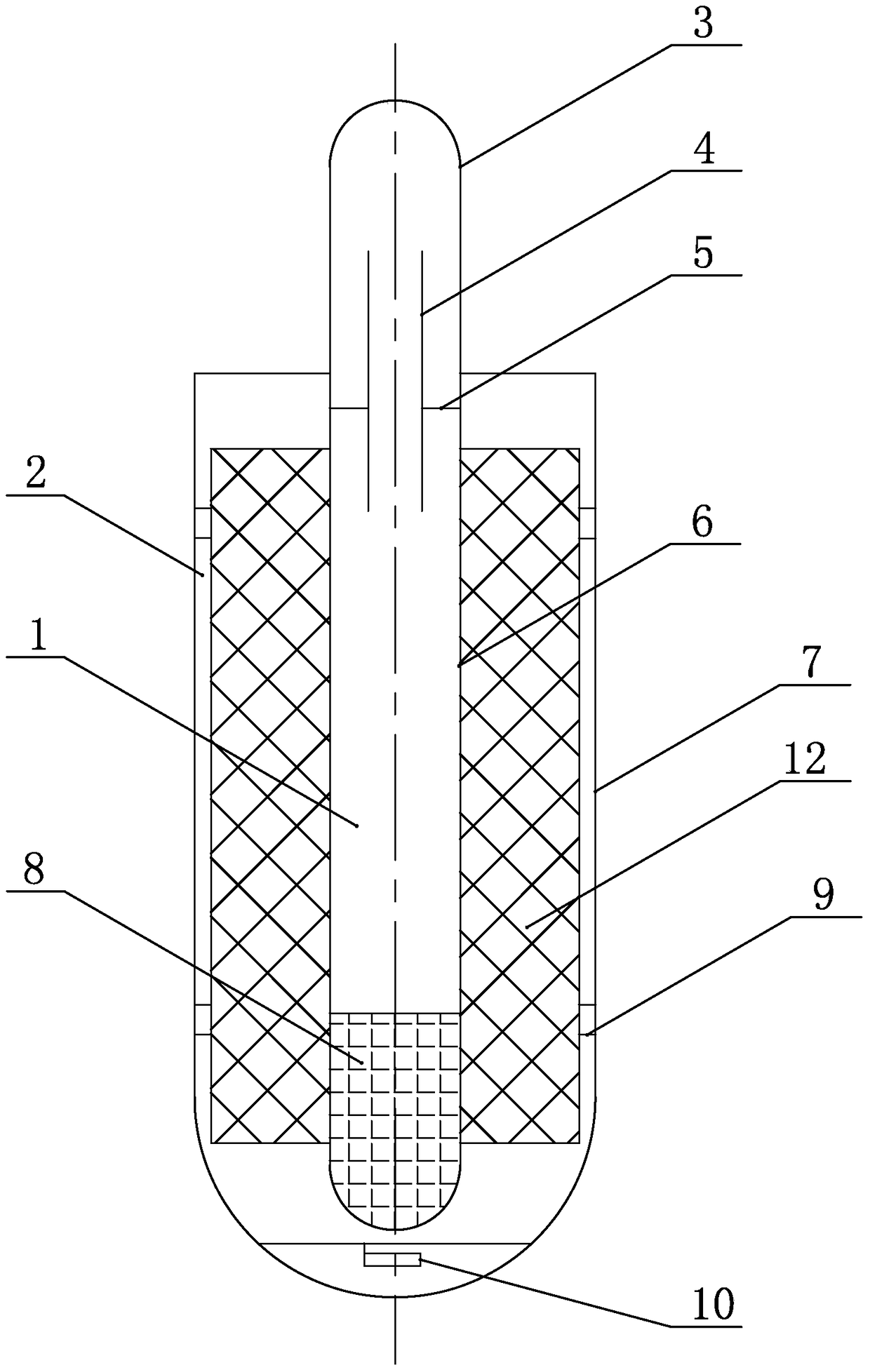

[0036] Example 3, such as image 3 As shown, the difference between this embodiment and Embodiment 1 lies in that: a CPC reflector 12 is arranged in the outer vacuum cavity 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com