Industrial treatment method and device for oil field waste

A technology for oilfield waste and industrial treatment, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, earthwork drilling and production, etc. It can solve the problems of low heating efficiency, high energy consumption, and low economic efficiency, and achieves fast heating rate, The effect of reducing energy consumption and increasing gasification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

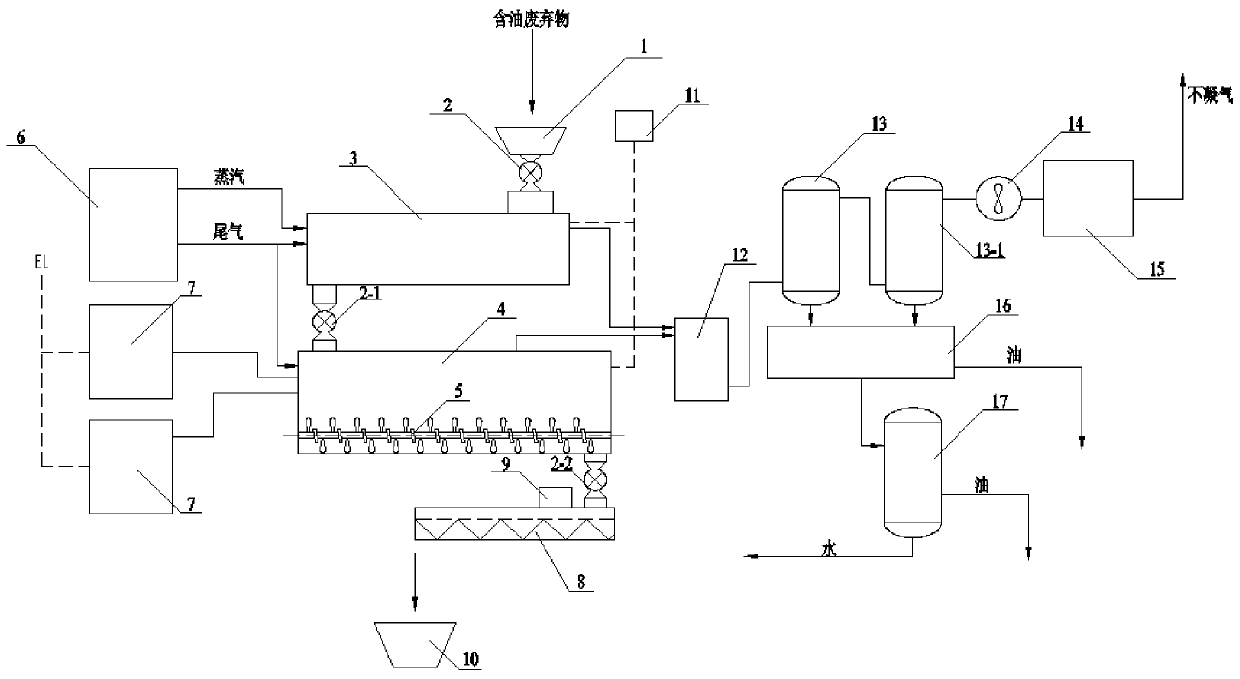

[0060] The industrial treatment device and technological process of the oilfield waste provided by embodiment 1, such as figure 1 shown.

[0061] figure 1 Among them, the feed hopper (1) is connected to the dryer (3) through an air lock (2), and the steam outlet of the steam boiler (6) is connected to the steam inlet of the dryer (3).

[0062] The discharge end of the dryer (3) is connected to the feed end of the microwave heating cavity (4) through an air lock (2-1), and the microwave generator (7) is connected to the microwave heating cavity (4) through a wave guiding device. A paddle conveyor (5) is arranged in the microwave heating chamber (4).

[0063] The gas outlets of the dryer (3) and the microwave heating chamber (4) are connected to the dust remover (12), and the dust remover (12) is connected to the condenser (13) and the condenser (13-1) in turn, and the condenser (13 -1) The gas outlet is connected with the UV high-efficiency gas purifier (15) through the fan ...

Embodiment 2

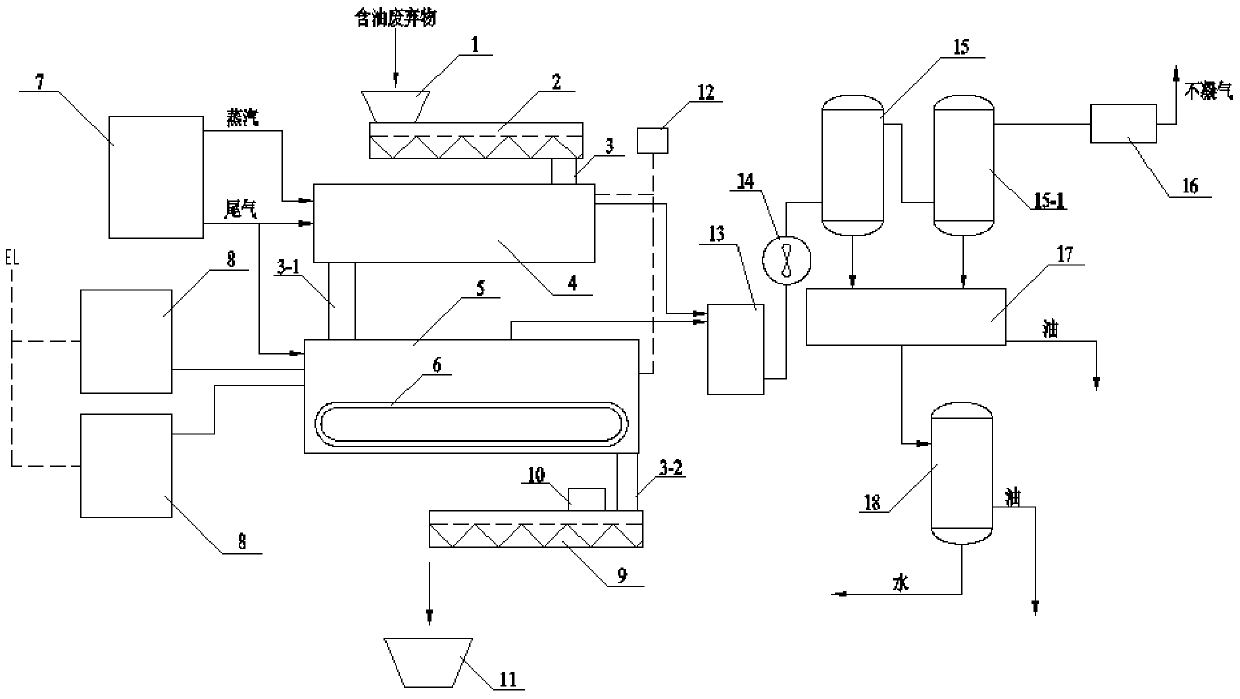

[0070] The industrial treatment device and technological process of the oilfield waste provided by embodiment 2, such as figure 2 shown.

[0071] figure 2 Among them, the feed hopper (1) is connected to the dryer (4) through the feed screw (2) and the rotary feeding device (3), and the steam outlet of the steam boiler (7) is connected to the steam inlet of the dryer (4). The discharge end of the dryer (4) is connected to the feed end of the microwave heating cavity (5) through the rotating unloading device (3-1), and the microwave generator (8) is connected to the microwave heating cavity (5) through a wave guiding device . A feeding conveyor belt (6) is arranged in the microwave heating chamber (5).

[0072] The gas outlets of the dryer (4) and the microwave heating chamber (5) are respectively connected with the dust remover (13), the fan (14), the condenser (15) and the condenser (15-1) in turn, and the condenser (15- 1) The gas outlet is connected to the UV high-effi...

Embodiment 3

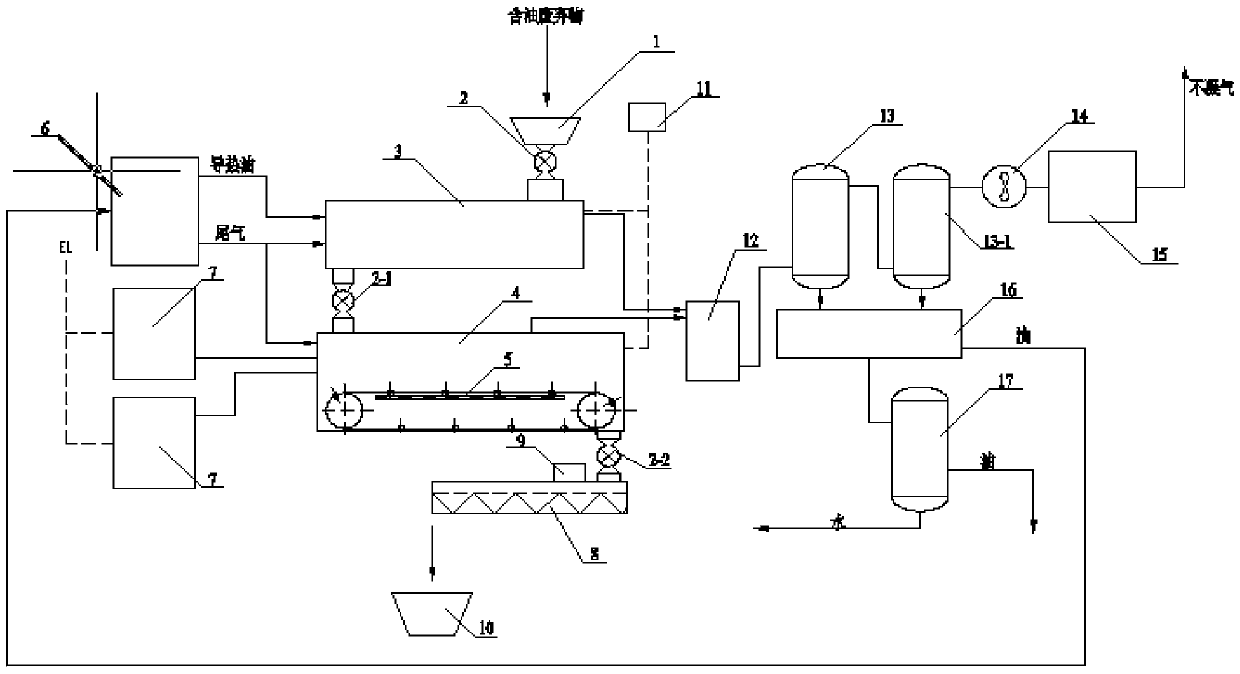

[0078] The industrial treatment device and technological process of the oilfield waste provided by embodiment 3, such as image 3 shown.

[0079] image 3 Among them, the feed hopper (1) is connected to the dryer (3) through an air lock (2), and the heat transfer oil outlet of the heat transfer oil boiler (6) is connected to the heat transfer oil inlet of the dryer (3).

[0080] The discharge end of the dryer (3) is connected to the feed end of the microwave heating cavity (4) through an air lock (2-1), and the microwave generator (7) is connected to the microwave heating cavity (4) through a wave guiding device. A scraper conveyor (5) is arranged in the microwave heating cavity (4).

[0081] The gas outlets of the dryer (3) and the microwave heating chamber (4) are respectively connected to the dust collector (12), the condenser (13) and the condenser (13-1) in turn, and the gas outlet of the condenser (13-1) Connect with activated carbon filter (15) through blower fan (14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com