Treated surface aluminum material and manufacturing method therefor as well as said treated surface aluminum material/resin layer bonded material

A technology of surface treatment and manufacturing method, applied in the direction of surface reaction electrolytic coating, chemical instrument and method, coating, etc., can solve the problem of resin adhesion reduction and other problems, achieve excellent adhesion and adhesion, stable manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~33 and comparative example 1~12

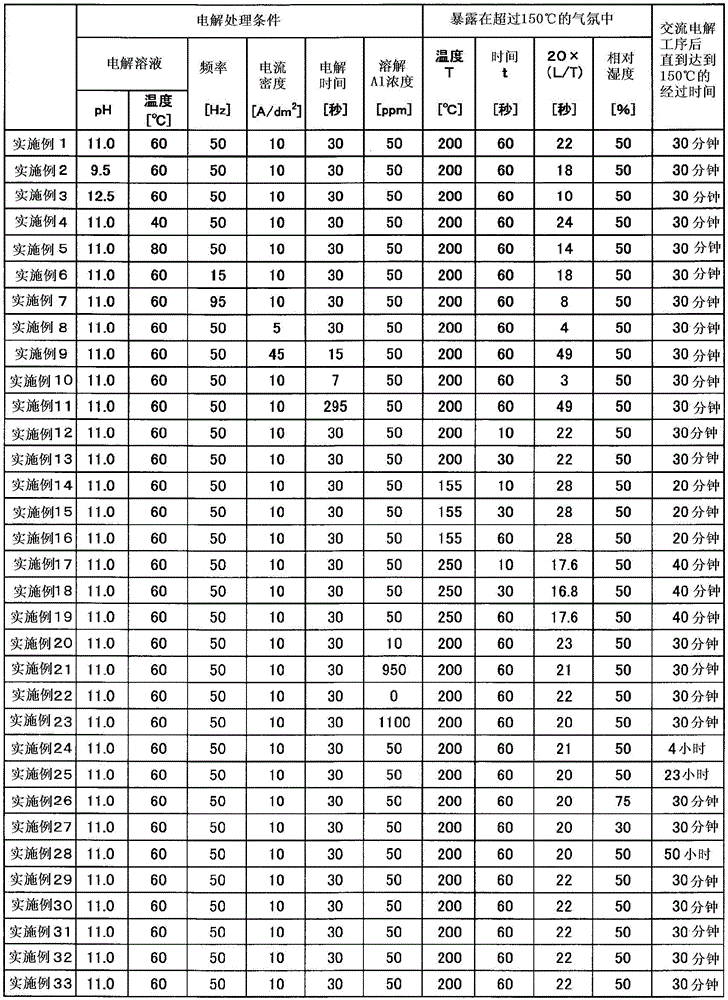

[0080]As the aluminum material, a flat plate of JIS5052-H34 alloy of 200 mm in length×400 mm in width×1.0 mm in thickness was used. This aluminum alloy plate was used as one electrode, and a graphite plate having a flat plate shape of 300 mm in length x 500 mm in width x 2.0 mm in thickness was used as a counter electrode. One surface of the aluminum alloy plate faces the counter electrode, and two electrodes are arranged on the surface of the facing surface so that the porous aluminum oxide coating layer on the surface side and the barrier aluminum oxide coating layer on the substrate side are formed. An alkaline aqueous solution containing sodium pyrophosphate as the main component is used as the electrolytic solution. The concentration of the alkali component of the electrolytic solution was set to 0.5 mol / liter, and the pH was adjusted with hydrochloric acid and aqueous sodium hydroxide solution (both concentrations were 0.1 mol / liter). Under the electrolytic conditions s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com