Drum type natural gas drying device

A drying device and natural gas technology, applied in the direction of gas fuel, petroleum industry, dispersed particle separation, etc., can solve the problems of adsorbent failure, high frequency of adsorbent replacement, short use time, etc., to reduce the amount of water vapor and improve drying effect, the effect of accelerating the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

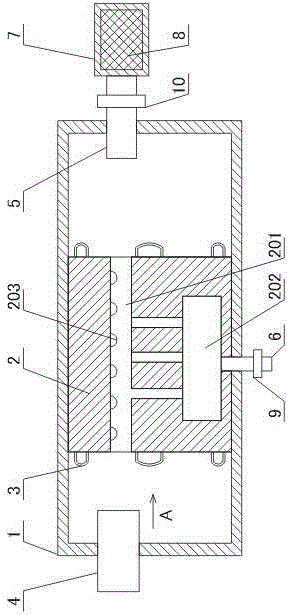

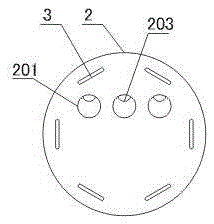

[0026] Such as figure 1 and figure 2 As shown, the cylindrical natural gas drying device includes a drying chamber 1, a condensation column 2, a condensation pipe 3, an air inlet pipe 4, an air outlet pipe 5, a liquid outlet pipe 6, a drying pipe 7, and an adsorbent 8; the condensation column 2 is set with the drying chamber In 1, the condensation pipe 3 reciprocates through the condensation column 2 in the circumferential direction of the condensation column 2. A plurality of horizontal flow channels 201 are opened on the condensation column 2, and a liquid collection cavity 202 is opened at the lower part of the condensation column 2. The liquid collection cavity 202 is located at Below the horizontal flow channel 201, the liquid collection cavity 202 communicates with each horizontal flow channel 201; the air inlet pipe 4 is arranged on the left side of the drying chamber 1, the air outlet pipe 5 is arranged on the right side of the drying chamber 1, and the liquid outlet ...

Embodiment 2

[0030] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a second shut-off valve 10 disposed on the air outlet pipe 5 .

[0031] The second stop valve 10 is provided, and when the natural gas is not dried, the second stop valve 10 is closed to prevent the condensed water in the liquid collection cavity 202 from evaporating and entering the drying pipe 1, further improving the service life of the adsorbent 9.

Embodiment 3

[0033] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1 or 2, a plurality of hemispherical protrusions 203 are provided on the upper inner surface of the horizontal flow channel 201 .

[0034] The condensed water located on the upper part of the inner surface of the horizontal flow channel can collect along the outer surface of the hemispherical protrusion 203, and finally gather into droplets at the lowest point of the hemispherical protrusion 203 and fall down. Compared with the condensed water flowing downward along the inner surface of the horizontal flow channel, Its condensate drains faster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com