Formed coke and production method of formed coke, coal gas and tar

A production method and drying-based technology, which can be applied in coking ovens, petroleum industry, and gas purification of condensed non-gaseous materials, etc., can solve the problems of high production costs, and achieve the effects of low production costs, low moisture content, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

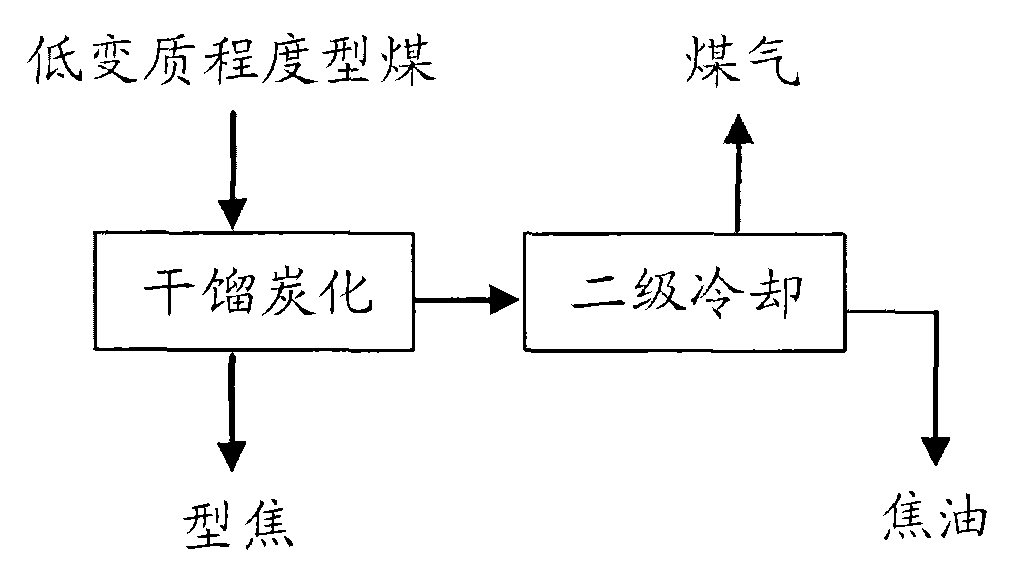

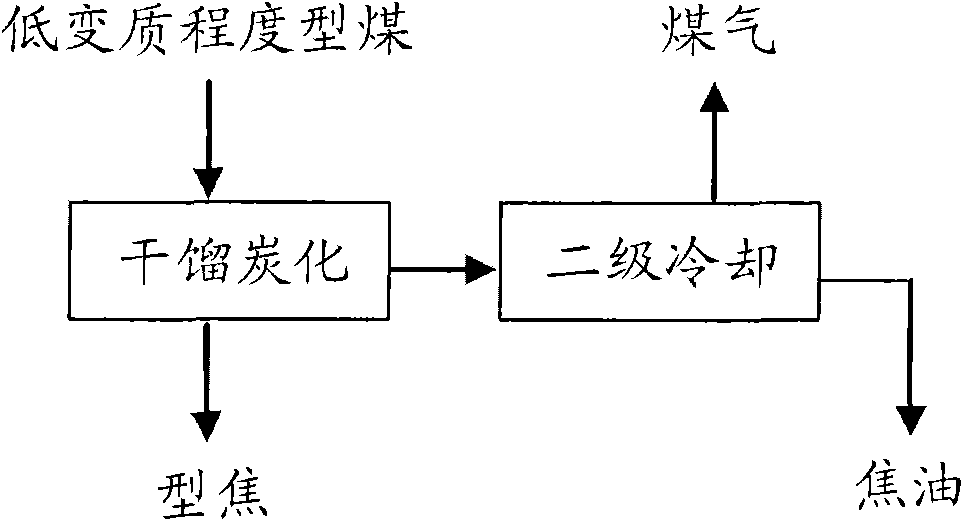

Method used

Image

Examples

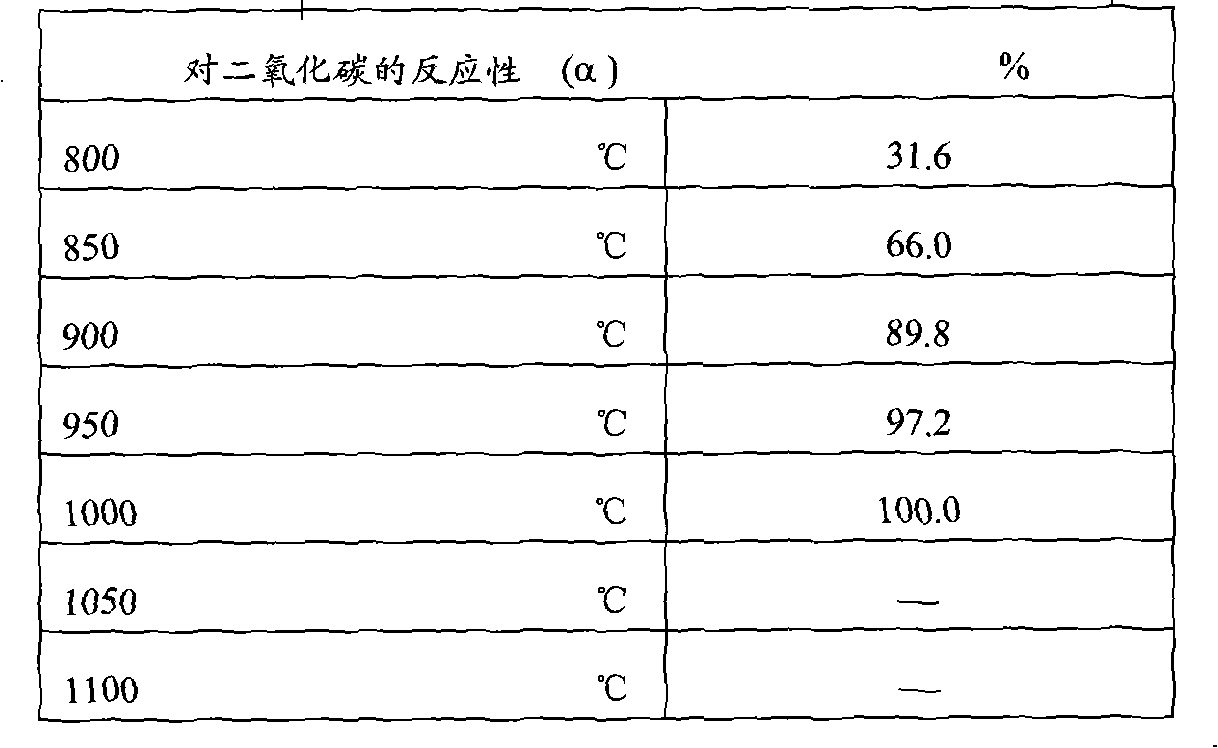

Embodiment 1

[0035] The air-dried basis moisture content is 7.83 mass%, the dry basis ash content is 9.34 mass%, the dry basis volatile content is 39.54 mass%, the dry basis fixed carbon content is 51.12%, the dry basis high calorific value is 6232 cal / g, and the particle size is 24 The briquette raw material of lignite briquette of ×32×5mm was put into an externally heated carbonization furnace (not shown in the figure) to carry out carbonization test. Set the heating rate to 10-15°C / min, and keep the temperature at 900°C for 2 hours to produce lignite shaped coke. The dry base ash content of the obtained molded coke is 18.74% by mass, and the dry base volatile content is 2.93% by mass. The base fixed carbon content is 78.88% by mass, the cold compressive strength is over 400 N / ball, the heat stability is over 96%, and the dry base high calorific value is 6648 cal / g.

[0036] Secondary cooling is used for separation, wherein the outlet temperature of the primary condenser is 40-80°C, and ...

Embodiment 2

[0038] The air-dried basis moisture content is 7.83 mass%, the dry basis ash content is 9.34 mass%, the dry basis volatile content is 39.54 mass%, the dry basis fixed carbon content is 51.12%, the dry basis high calorific value is 6232 cal / g, and the particle size is 24 The briquette raw material of lignite briquette of ×32×5mm was put into an externally heated carbonization furnace (not shown in the figure) to carry out carbonization test. Set the heating rate at 10-15°C / min, and keep the temperature at 850°C for 2 hours to produce lignite shaped coke. The dry base ash content of the obtained molded coke is 18.71% by mass, and the dry base volatile content is 4.28% by mass. The base fixed carbon content is 77.81% by mass, the cold compressive strength is over 400 N / ball, the heat stability is 96.8%, and the dry base high calorific value is 6624 cal / g.

[0039] Secondary cooling is used for separation, wherein the outlet temperature of the primary condenser is 40-80°C, and the...

Embodiment 3

[0041]The air-dried basis moisture content is 7.83 mass%, the dry basis ash content is 9.34 mass%, the dry basis volatile content is 39.54 mass%, the dry basis fixed carbon content is 51.12%, the dry basis high calorific value is 6232 cal / g, and the particle size is 24 The briquette raw material of lignite briquette of ×32×5mm was put into an externally heated carbonization furnace (not shown in the figure) to carry out carbonization test. Set the heating rate at 10-15°C / min, and keep the temperature at 800°C for 2 hours to produce lignite shaped coke. The dry base ash content of the obtained molded coke is 18.80% by mass, and the dry base volatile content is 3.81% by mass. The base fixed carbon content is 78.67% by mass, the cold compressive strength is over 400 N / ball, the heat stability is over 96%, and the dry base high calorific value is 6729 cal / g.

[0042] Secondary cooling is used for separation, wherein the outlet temperature of the primary condenser is 40-80°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com