Controlling engine operation during diesel particulate filter regeneration to avoid runaway

a technology of diesel particulate filter and engine operation, which is applied in the direction of machines/engines, mechanical equipment, exhaust treatment electric control, etc., can solve the problems of increased stress in internal materials, more cracking of materials, and shock that cracks a substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

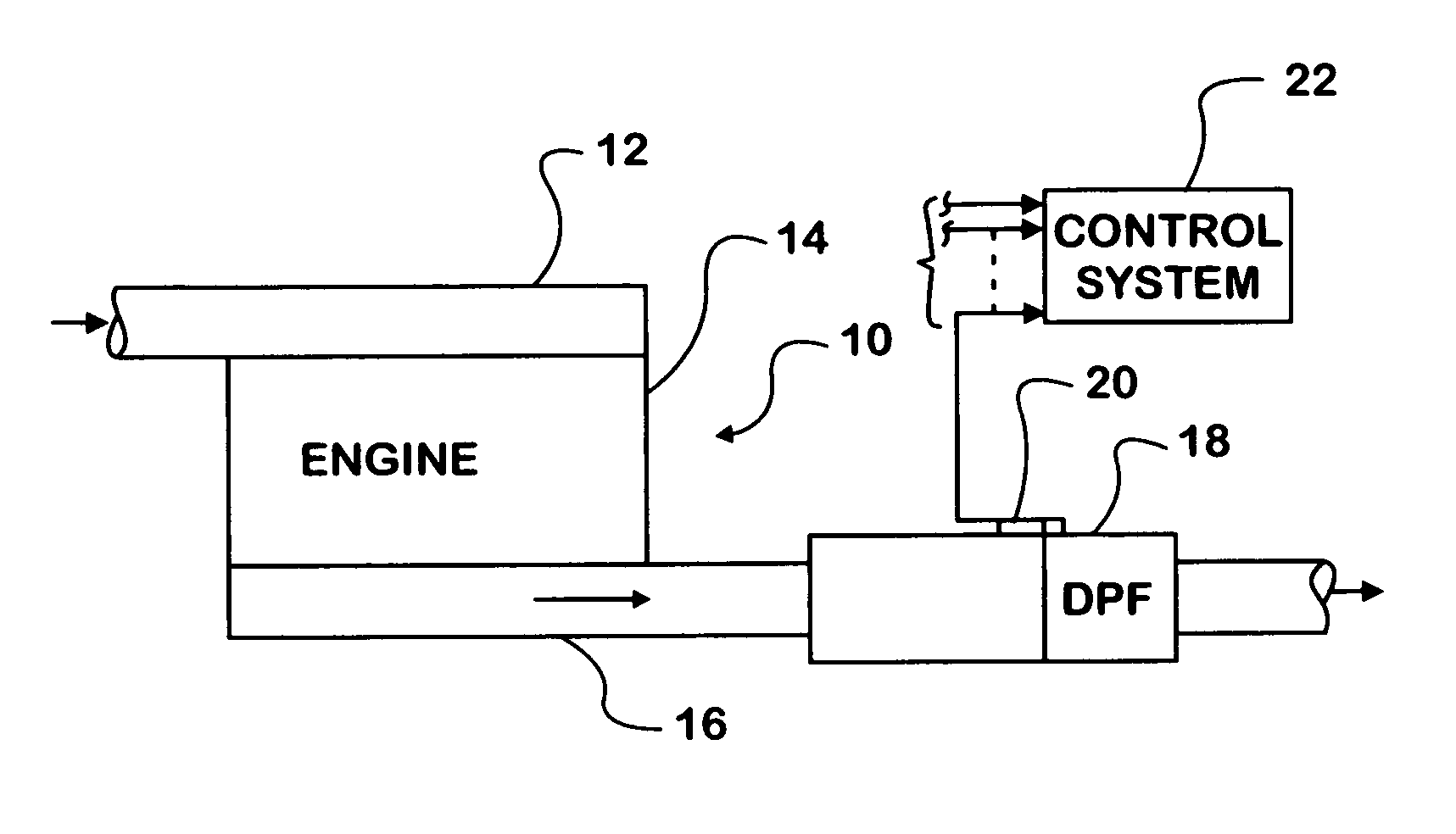

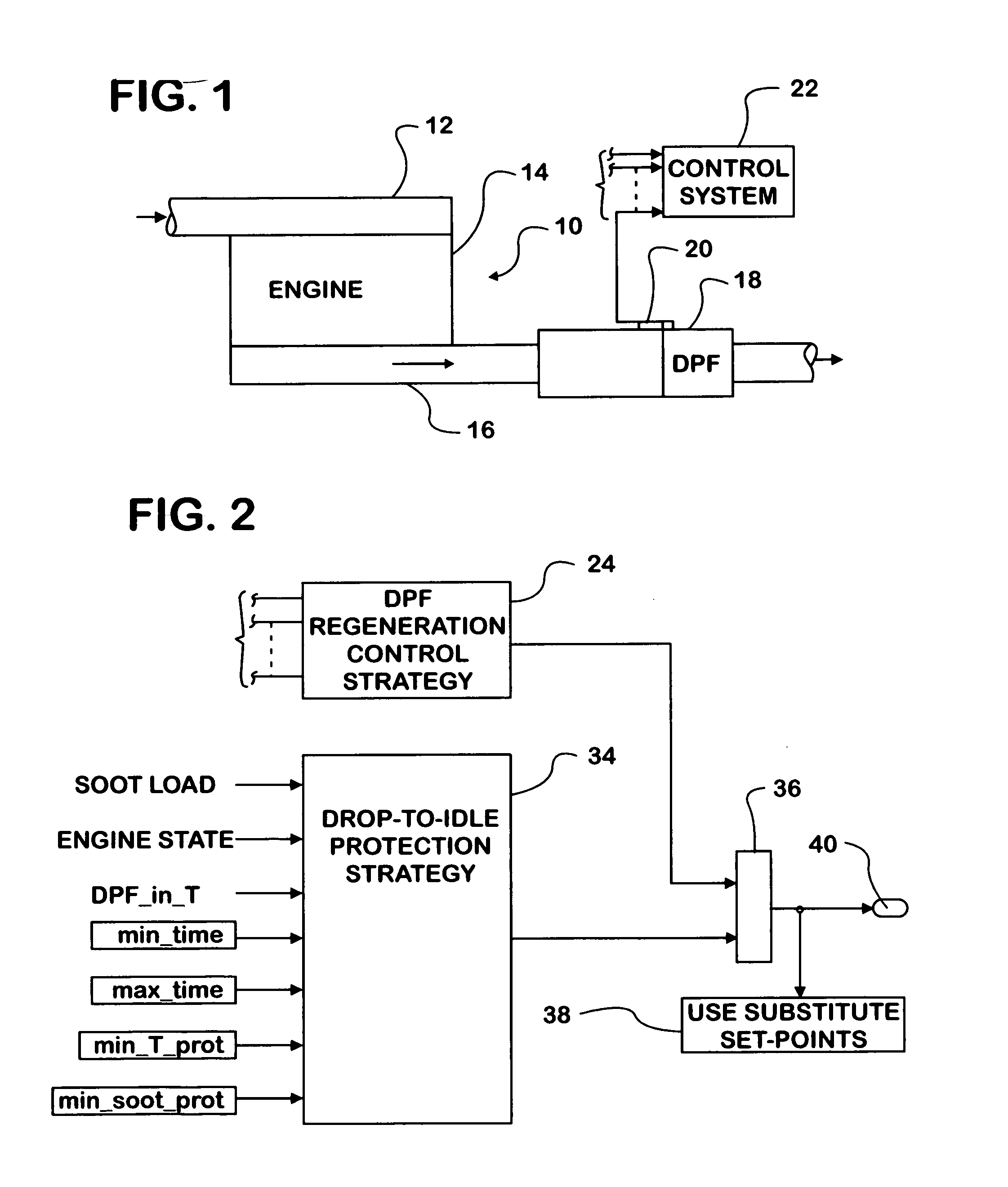

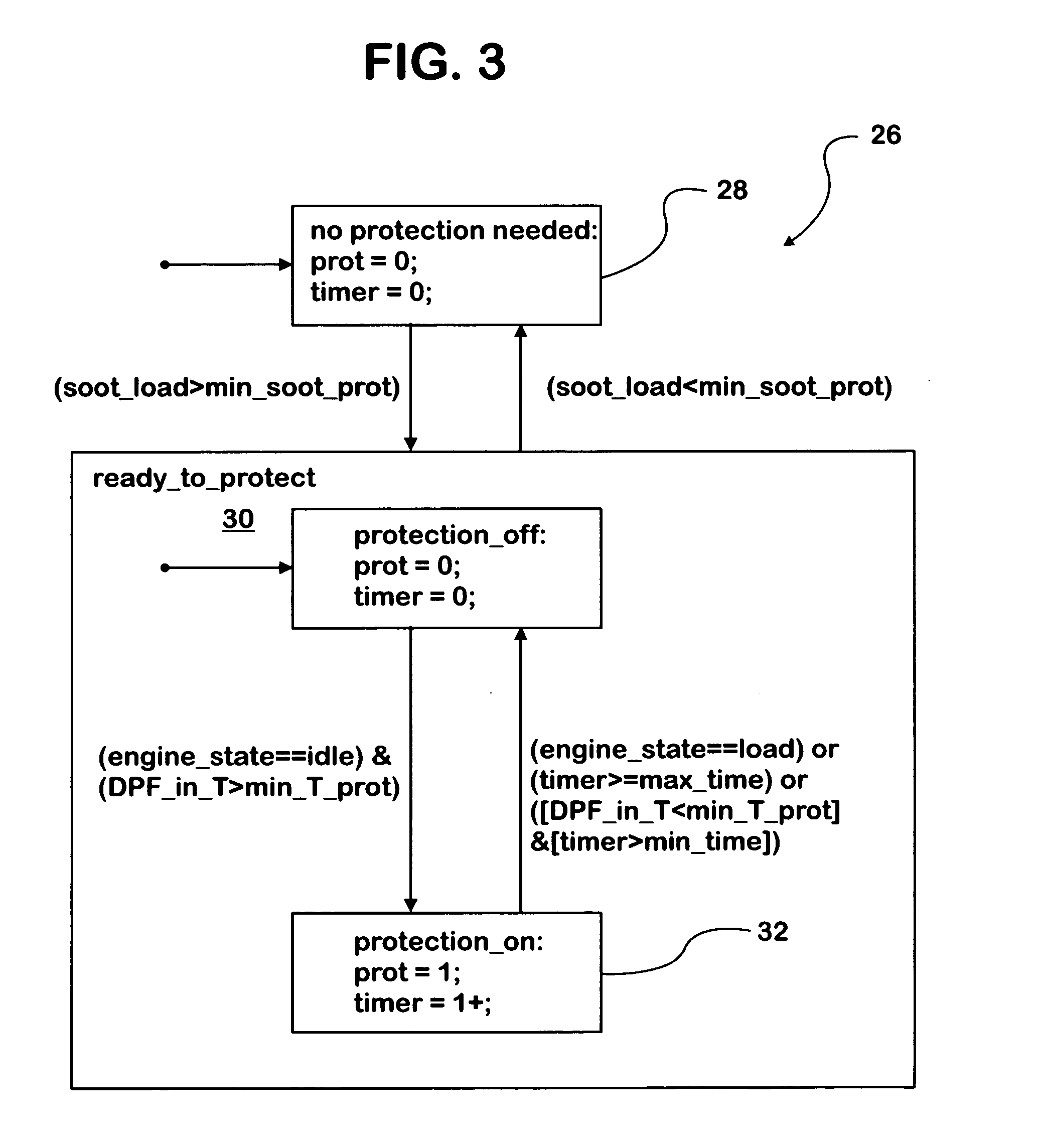

[0028]FIG. 1 shows a diesel engine 10 having an intake system 12 leading to an engine block 14 containing cylinders into which diesel fuel is injected by a fueling system and from which an exhaust system 16 conveys exhaust gases. Exhaust system 16 contains one or more exhaust after-treatment devices one of which is a diesel particulate filter (DPF) 18 having a catalyzed ceramic substrate for trapping diesel particulates.

[0029] When engine 10 is operating to propel a motor vehicle, such as a large truck, exhaust gas exits the engine combustion chambers to enter exhaust system 16 and pass through DPF 18 before eventually passing into the surrounding atmosphere.

[0030] Various sensors are associated with the after-treatment devices. One of them that is relevant to the specific embodiments discussed here is a DPF inlet temperature sensor 20 disposed to measure temperature at the inlet of DPF 18.

[0031] The inventive method is implemented in an engine control system 22 that processes va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com