Blowing type gas water heater constant temperature control method and control system thereof

A gas water heater and constant temperature control technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of insufficient gas supply, unusable water heaters, and the water outlet temperature of the water heater cannot reach the set temperature, etc. The effect of load Q, reducing workload, and increasing air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

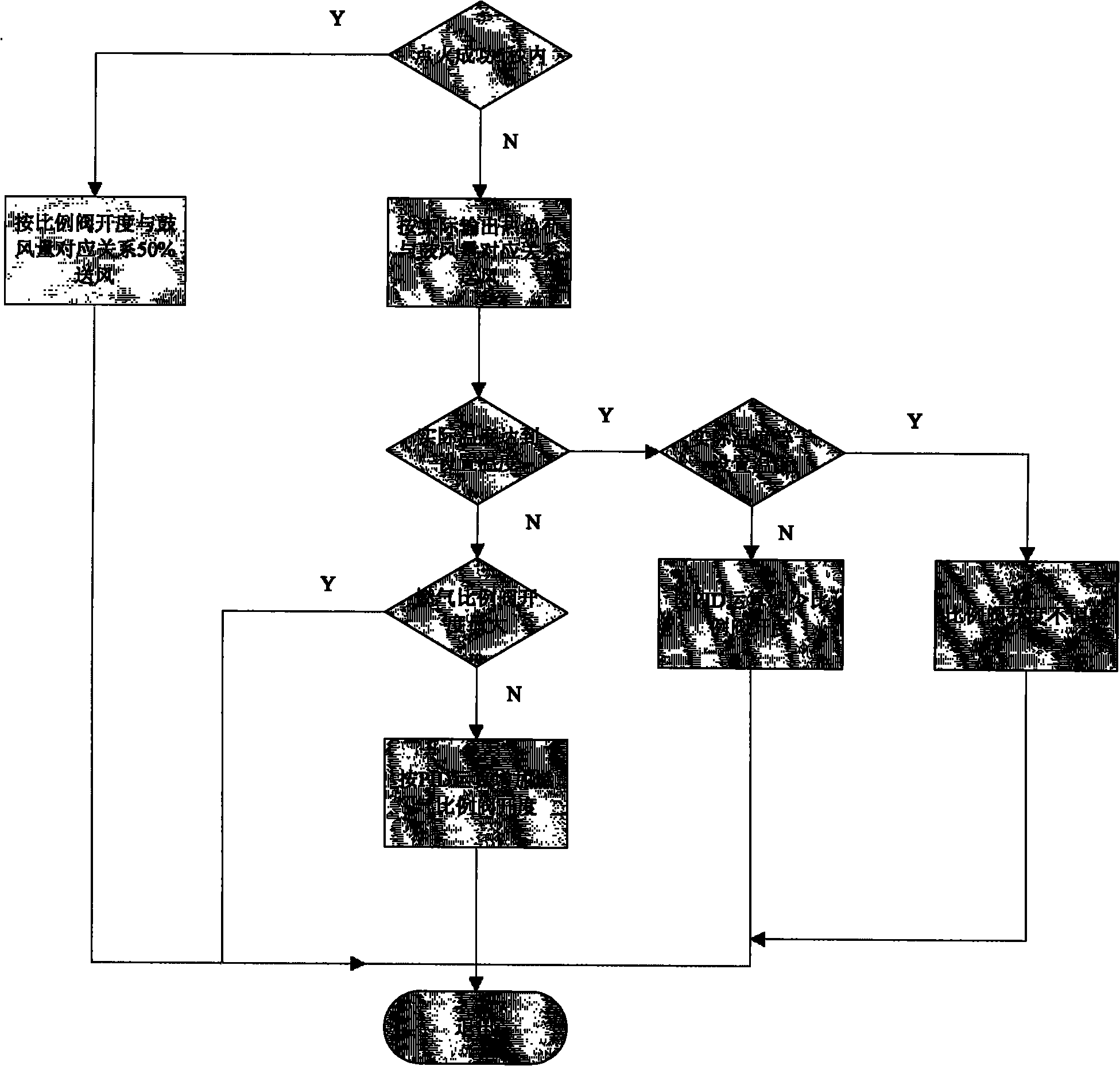

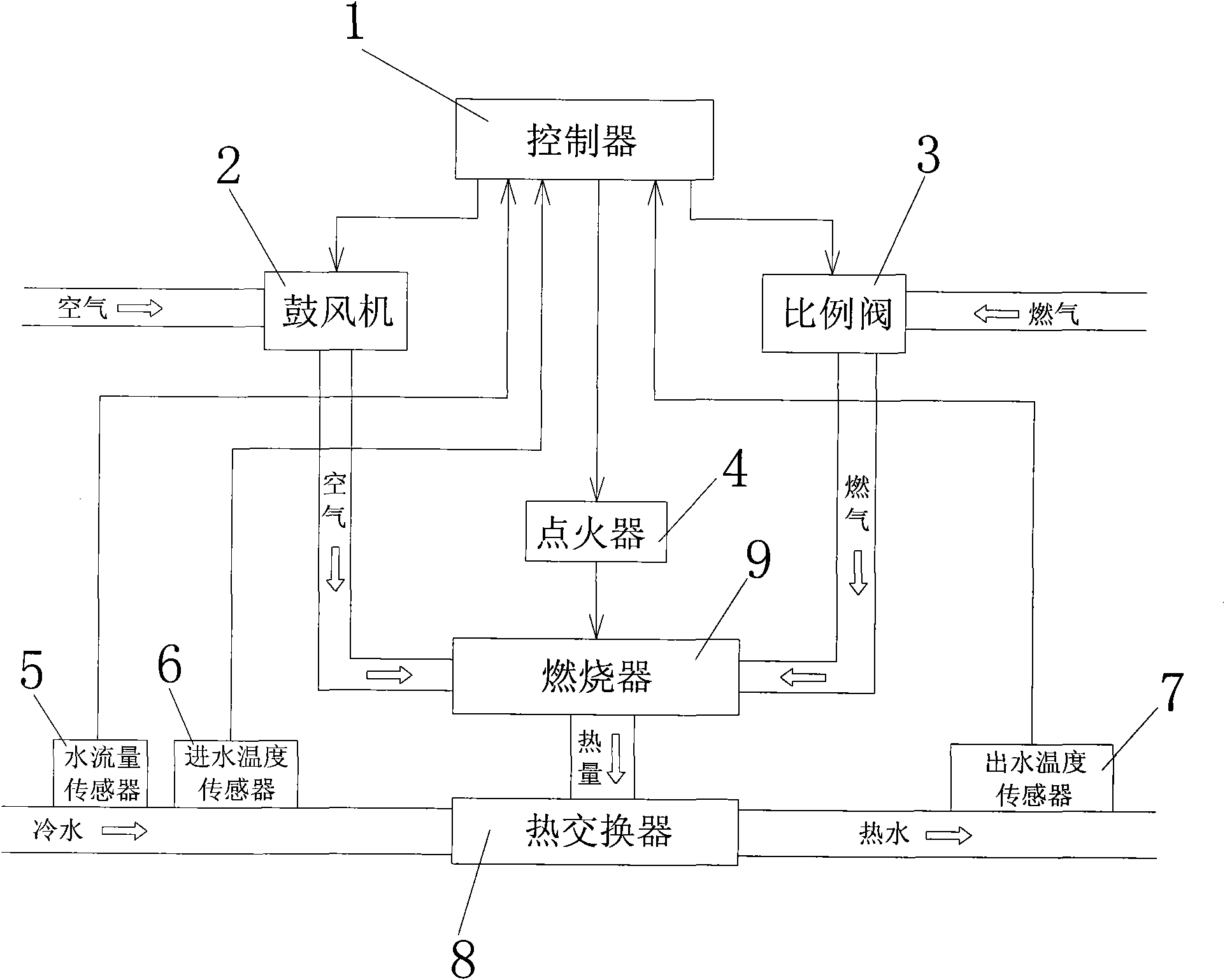

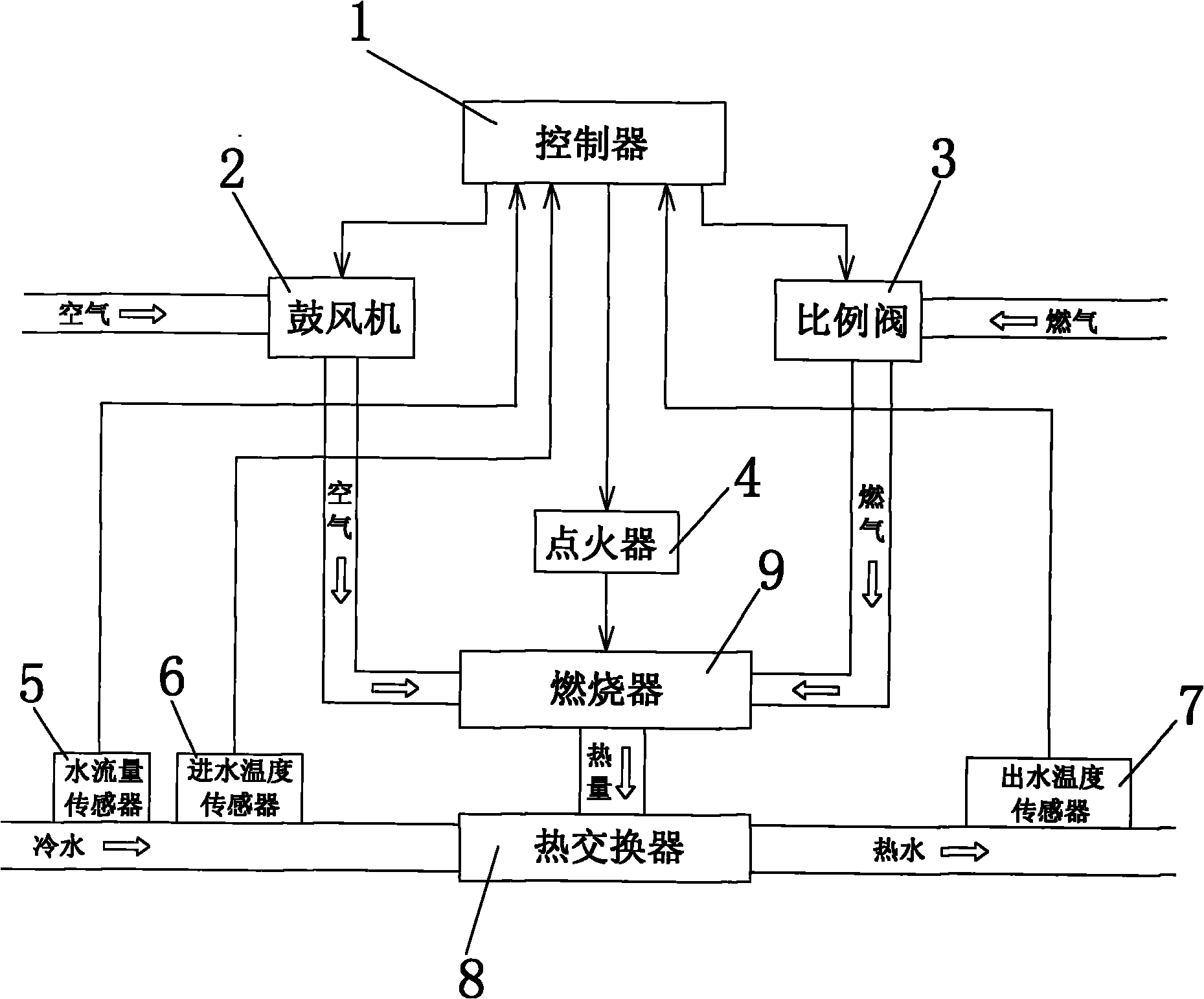

[0015] Such as figure 2 As shown, a constant temperature control system for a blast type gas water heater includes a central controller 1, a blower 2, a gas proportional valve 3, an igniter 4, a water flow sensor 5, an inlet water temperature sensor 6, and an outlet water temperature sensor 7. The output end of the controller 1 is electrically connected to the input end of the blower 2, the gas proportional valve 3 and the igniter 4, and the input end of the controller 1 is connected to the output ends of the water flow sensor 5, the water inlet temperature sensor 6 and the water outlet temperature sensor 7, The igniter 4 controls the burner 9 to enter the combustion state. When using the water heater, open the water valve, the water flow sensor 5 detects the water flow signal V, and transmits the water flow signal V to the controller 1, and the controller 1 according to the water flow signal V V starts the blower 2 and the igniter 4, and opens the gas proportional valve 3, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com