Device for detecting specific surface area and aperture of dynamic and static powder

A technology of specific surface area and detection device, which is applied in measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of high vacuum degree, low detection accuracy and high detection cost. The effect of low detection cost, high detection efficiency and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

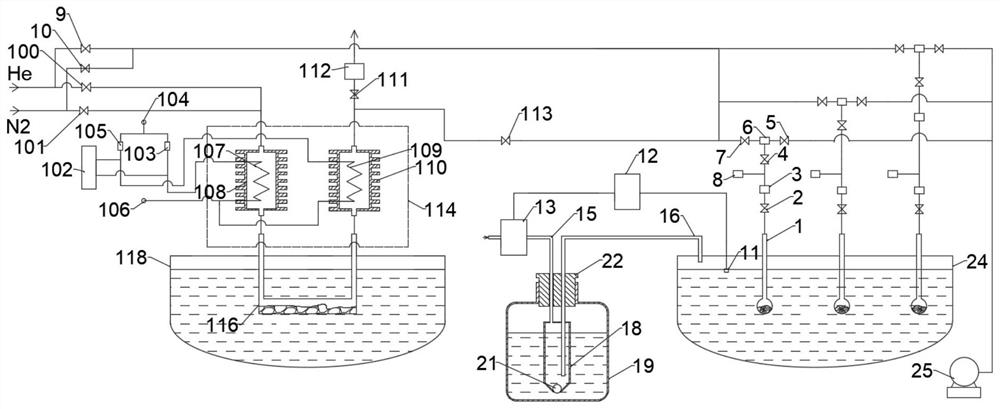

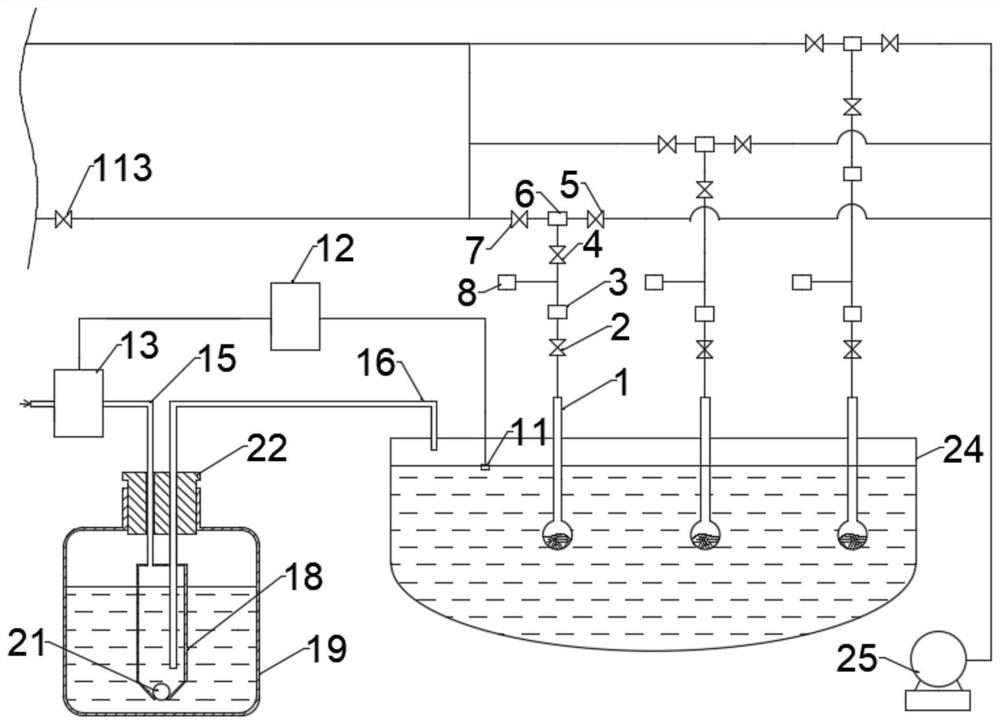

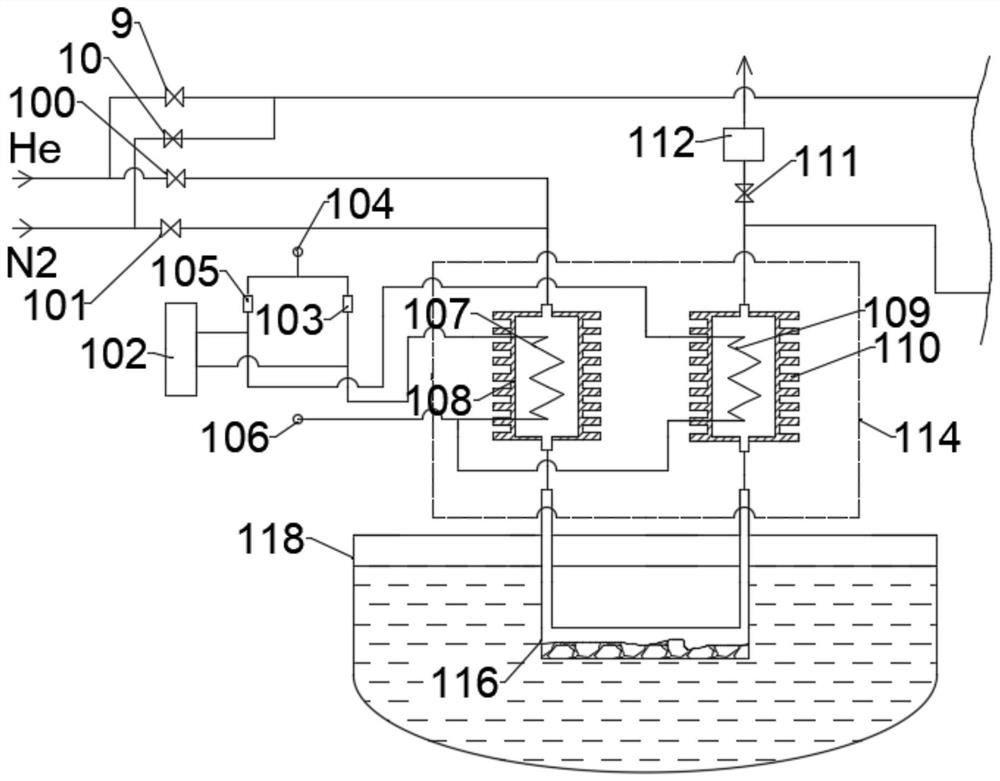

[0039] Such as Figure 1-Figure 3 As shown, this embodiment provides a dynamic and static two-state powder specific surface area and pore size detection device, including: a static detection component for detection by a static method, a dynamic detection component and an air supply component for detection by a dynamic method.

[0040] The output ends of the gas supply part communicate with the static detection part and the dynamic detection part respectively, and the standard gas is supplied to the static detection part and the dynamic detection part through the gas supply part.

[0041] The detection device adopts the combination of static method detection and dynamic method detection, and can use static method detection or dynamic method detection according to the situation, and can also use two kinds of detection at the same time. The detection efficiency is high, and the detection accuracy is also improved at the same time. Costs are reduced.

[0042]Preferably, in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com