Method for CNG gas-adding station realizing arbitrary variable intake pressure

A technology of air intake pressure and realization method, which is applied in the direction of equipment loaded into pressure vessels, container filling methods, liquid variable capacity machinery, etc., which can solve the problem of reducing gas supply, wasting useful energy, and determining stable gas supply and power consumption Difficulties and other problems, to achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

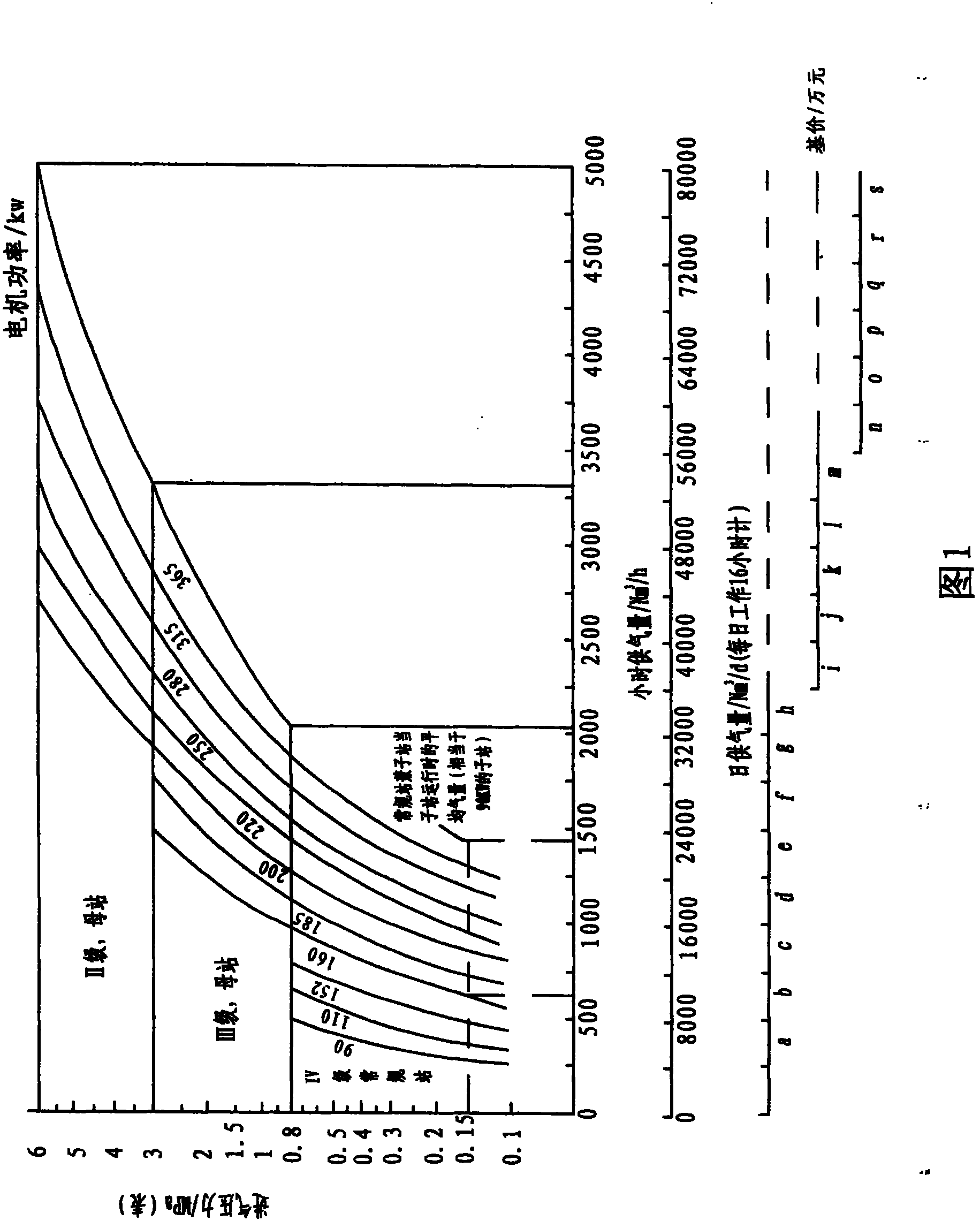

[0016] see figure 1 , figure 1 It is a series of spectral diagrams of the present invention. The gas filling station compressor is a series of products. There are three counter-moving bases, and the corresponding piston forces are 6-8 tons, 9-12 tons, and 13-16 tons. The cylinder structure includes a double-acting medium-pressure cylinder; a low-medium pressure inverted differential cylinder; and an inverted differential high-pressure cylinder. Each compressor is based on the motor power, and each power motor can adapt to various intake pressures and various air supply volumes. According to the type spectrogram, the working stages of the compressor are determined according to the inlet pressure range. When the natural gas pressure in the pipeline is 0.15MPa-0.7MPa, the compressor adopts four-stage compression; when the natural gas pressure in the pipeline is 0.8MPa-2.5MPa, The compressor adopts three-stage compression; when the natural gas pressure in the pipeline is 2.5MPa~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com