RH injection refining device and application thereof

A refining device and powder spraying technology, which is applied in the field of iron and steel metallurgy, can solve problems such as instability and high difficulty, and achieve the effects of low cost, convenient operation, and enhanced removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

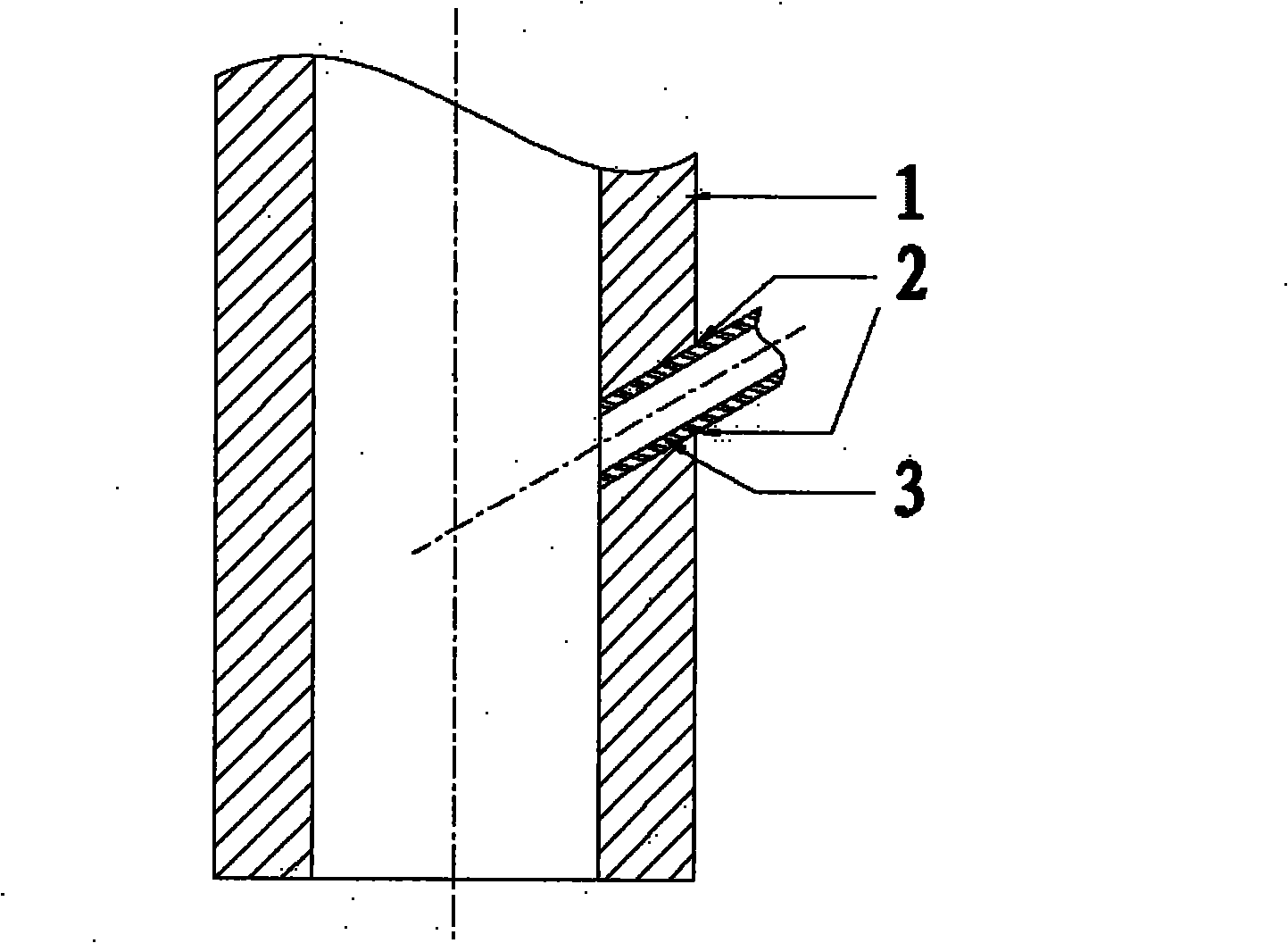

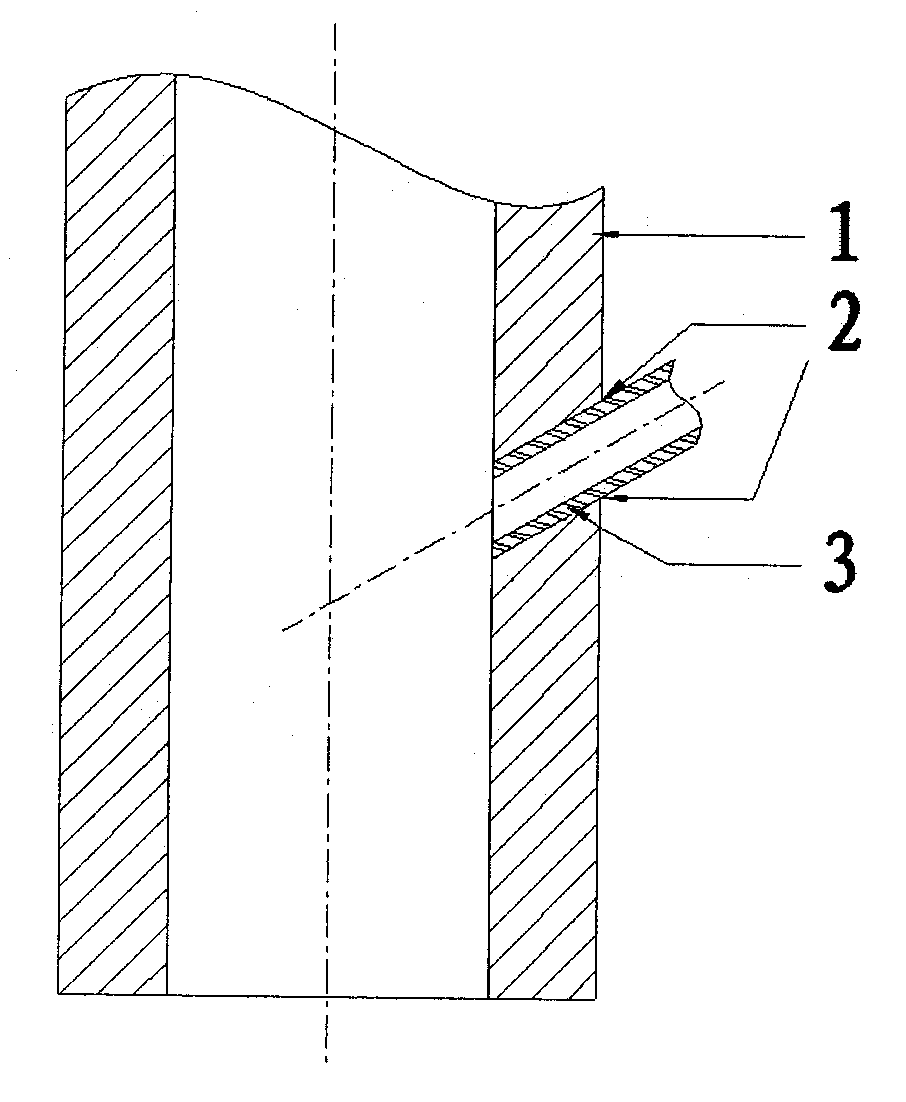

[0024] Drill a hole in the tube wall 1 of the lower part of the RH downcomer, and the number of through hole 2 is 1. The position of the through hole 2 is 400mm away from the lower edge of the RH downcomer. On the outer shell of the chamber, an interface is reserved in the extension part, and the interface is connected to an external air source. The inner diameter of the nozzle 3 is 5mm, and the axial direction of the through hole 2 is at an angle of 30° with the axial direction of the RH downcomer.

[0025] To remove small inclusions in steel, the process is as follows:

[0026] Using an external gas source, Ar gas is injected during net circulation after deoxidation alloying (using Al deoxidation), the injection time is 7-8min, the gas flow rate is 300L / min, and the gas supply pressure is 4.0atm. The blown gas is dispersed into fine bubbles under the impact of the falling molten steel, and the bubbles float up in the ladle, and at the same time collide with and adhere to the...

Embodiment 2

[0028] Drill holes in the tube wall 1 of the lower part of the RH downcomer, and the number of through holes 2 is 2. The position of the through hole 2 is 200mm away from the lower edge of the RH downcomer. The two through holes are distributed along the radial direction of the RH downcomer. The axial angle between the two holes is 60°, the nozzle 3 is introduced into the through hole 2, the nozzle 3 extends outward, and is fixed on the vacuum chamber shell, and the extension part leaves an interface, which is connected to an external air source. The inner diameter of the nozzle 3 is 4mm, and the through hole 2 The axial direction and the axial direction of the RH downcomer form an angle of 45°.

[0029] To remove small inclusions in steel, the process is as follows:

[0030] Using an external gas source, inject Ar gas during the net cycle after the deoxidation alloying (using Al deoxidation), the injection time is 7-8min, the single-tube gas flow rate is 100L / min, and the gas...

Embodiment 3

[0032] Drill holes in the tube wall 1 of the lower part of the RH downcomer, and the number of through holes 2 is 6. The position of the through holes 2 is 150mm away from the lower edge of the RH downcomer. The angle is 60°, the nozzle 3 is introduced into the through hole 2, and the nozzle 3 extends outward, and is fixed on the outer shell of the vacuum chamber. The axial direction of the hole 2 forms an included angle of 60° with the axial direction of the RH downcomer.

[0033] To remove small inclusions in steel, the process is as follows:

[0034] Using an external gas source, inject Ar gas during the net cycle after the deoxidation alloying (using Si deoxidation), the injection time is 6-7min, the single-tube gas flow rate is 50L / min, and the gas supply pressure is 4.0atm. The blown gas is dispersed into fine bubbles under the impact of the falling molten steel, and the bubbles float up in the ladle, and at the same time collide with and adhere to the inclusions to rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com