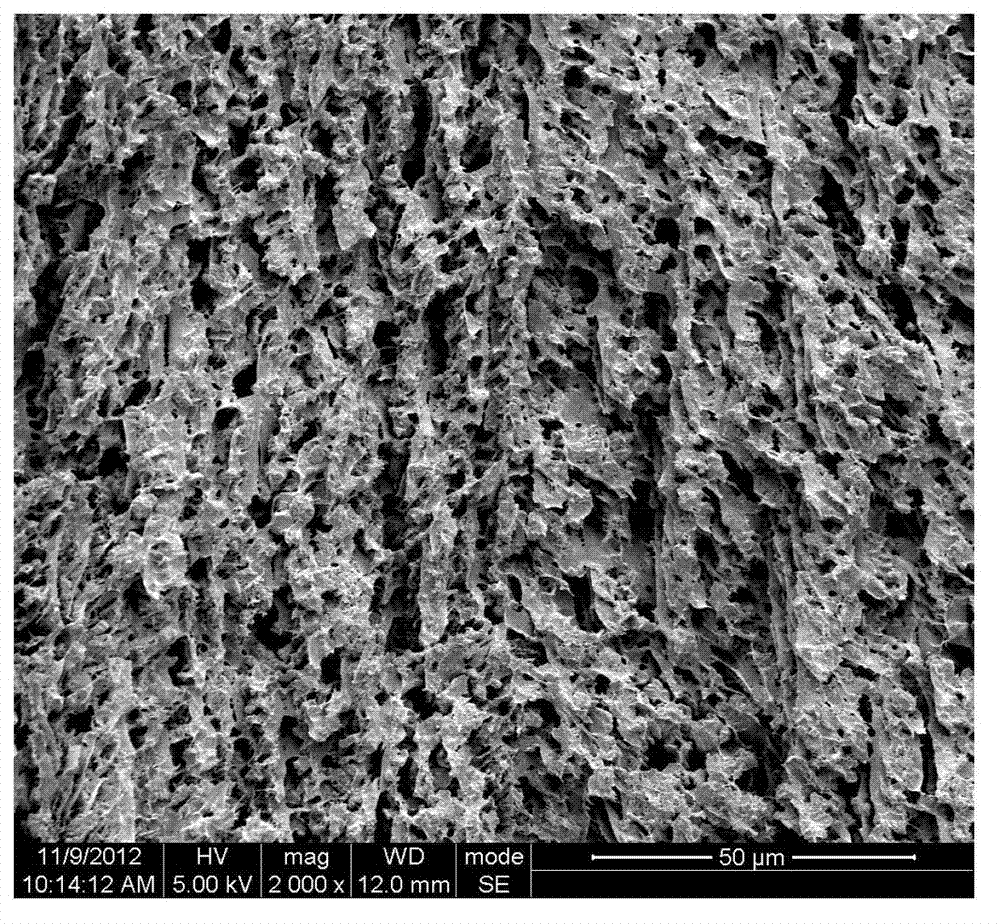

Inorganic micro/nanoparticle/polymer composite building thermal-insulation aerogel material and preparation method thereof

A technology of micro-nano particles and building insulation, applied in the field of nano-inorganic/polymer composite airgel materials and its preparation, can solve the problems of low flame retardancy, high proportion of polymer materials or binders, and no reports Specific indicators of flame retardant performance and thermal insulation performance, etc., to achieve the effect of low density, low thermal conductivity and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

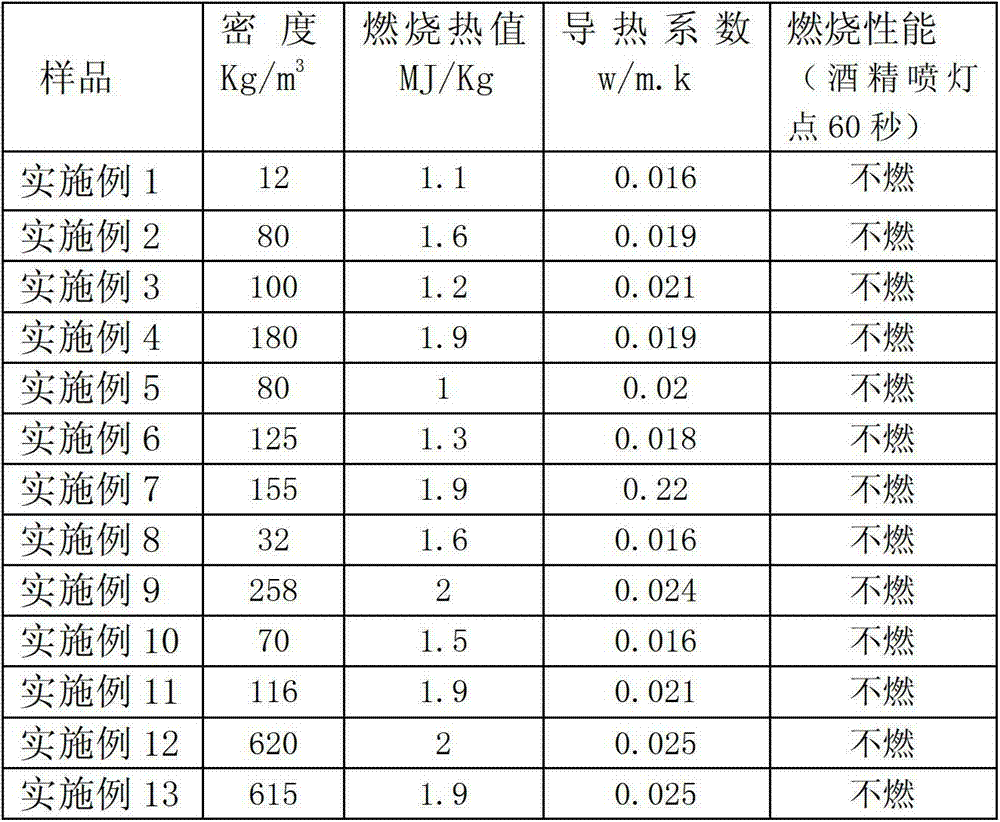

Examples

Embodiment 1

[0039] Add 0.5 parts of magnesium hydroxide, 0.1 parts of polyvinyl alcohol, 0.5 parts of wood fiber, and 0.1 parts of organosiloxane into 100 parts of water, stir evenly, freeze at -40°C until solid, and then use a freeze dryer at - Dry at 30°C for 168 hours.

Embodiment 2

[0041] Put 5 parts of magnesium hydroxide, 0.5 parts of methyl cellulose, 1 part of epoxy resin, 1 part of wood fiber, and 0.5 parts of organosiloxane into 100 parts of water, stir well and freeze at -60°C until completely frozen. The solid is then dried at -20°C for 48 hours with a freeze dryer, and then heated to 60°C for 24 hours to solidify.

Embodiment 3

[0043] Add 6 parts of aluminum hydroxide, 0.5 parts of sodium alginate, 1 part of thermosetting polyurethane resin, 14 parts of hemp fiber, and 0.5 part of polyether into 100 parts of water, stir evenly and freeze at -80°C until completely frozen into a solid, then After drying at -14°C for 48 hours with a freeze dryer, heat up to 40°C and solidify for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com