Pyrolysis and gasification device and technology

A technology of pyrolysis gasification and process, applied in the direction of granular/powdered fuel gasification, petroleum industry, coking carbonaceous materials, etc., can solve the problems of generating too much tar, reducing utilization efficiency, secondary pollution, etc., and achieve carbon reduction chain length, achieve material balance, and improve the effect of oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

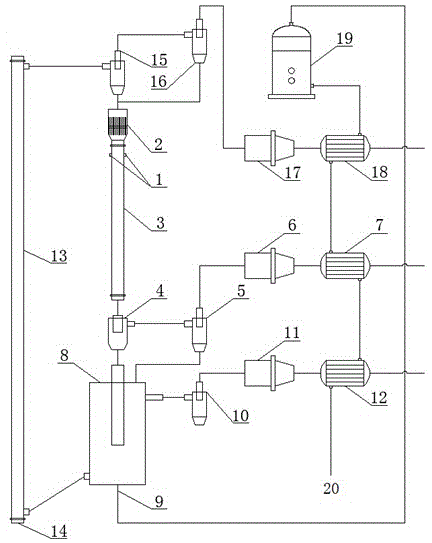

[0030] First, the pyrolysis gasification device is described:

[0031] Such as figure 1 Shown, a kind of pyrolysis gasification device is characterized in that, comprises three main reactors of burner, pyrolyzer, gasifier, and described pyrolyzer is down-bed rapid pyrolyzer 3, and gasifier is Bubbling bed gasifier 8, the burner is an ascending bed oxidation burner 13;

[0032] The upper part of the down-bed fast pyrolyzer 3 is provided with a raw material inlet 1, above the raw material inlet 1 is a distributor 2, and the bottom of the down-bed fast pyrolyzer 3 is connected to the inertial separator 4; the side of the inertial separator 4 is connected to the first cyclone separator in turn 5. The first bag filter 6, the first cooler 7; the bottom of the inertia separator 4 is connected to the bubbling bed gasifier 8; the upper end of the bubbling bed gasifier 8 is connected to the first cyclone separator 5, and a water Steam and oxygen inlet 9, the upper side of the bubbling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com