Biomass fluid bed combustion device and combustion method

A combustion method and biomass technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve problems such as slagging and deposition, ash agglomeration, alkali metal corrosion of metal equipment, etc., to improve combustion efficiency, reduce combustion loss, The effect of increasing dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

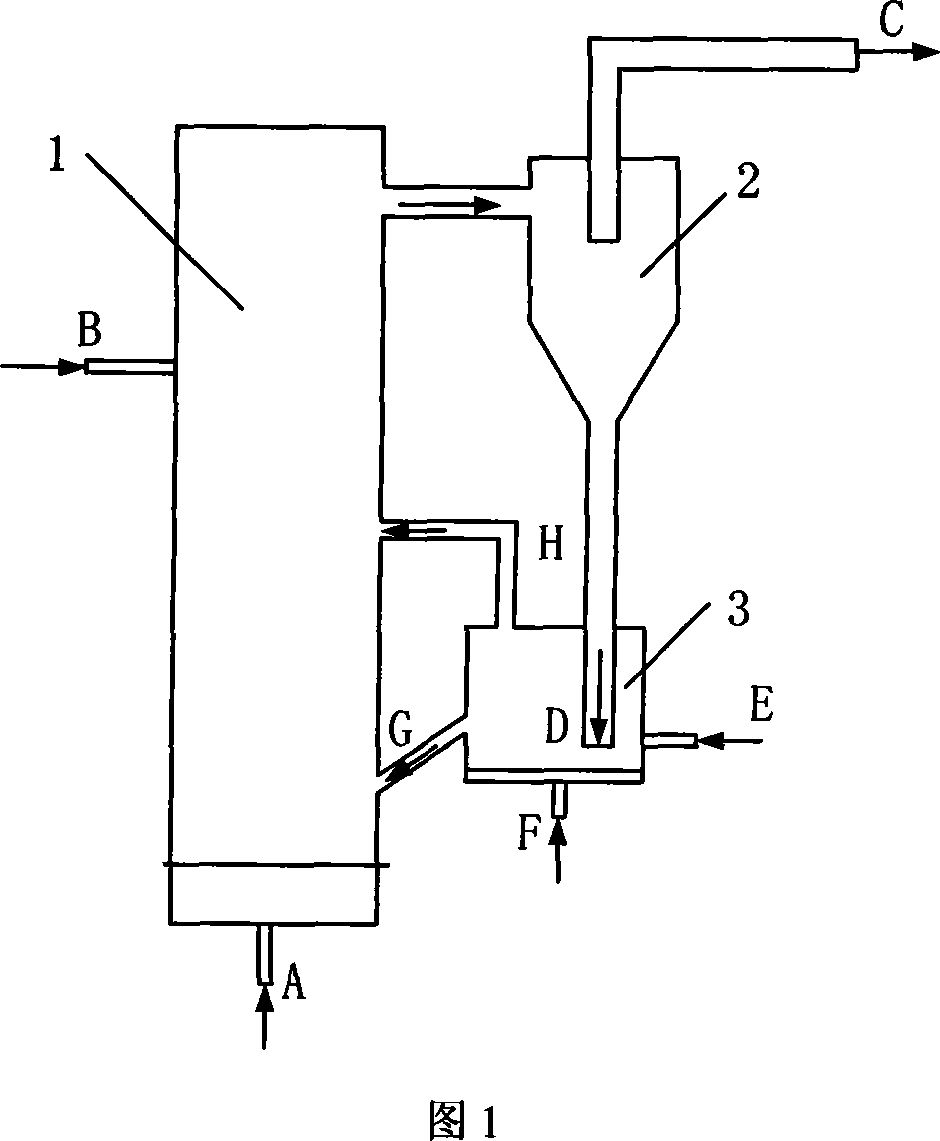

[0015] Below in conjunction with accompanying drawing, the present invention is described in detail, as shown in the figure, it comprises combustion reactor 1, respectively arranges an air inlet A and B at the bottom, upper middle part of combustion reactor 1, the top of combustion reactor and cyclone The separators 2 are connected, the top of the cyclone separator 2 is provided with a flue gas outlet C, and the lower end D of the cyclone separator 2 is passed into the pyrolysis gasification reactor 3, and the pyrolysis gasification reactor 3 is also provided with four ports, They are the air inlet F, the feed port E, the feed connecting pipe G connected to the combustion reactor 1, and the pyrolysis gas connecting pipe H. The feed connecting pipe G leads to the dense-phase combustion zone at the lower part of the combustion reactor 1, The pyrolysis gas connecting pipe H leads to the dilute-phase combustion zone in the middle or upper part of the combustion reactor 1 .

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com