Process for producing super-fine high-purity white carbon from rice hull and burning heat

A production process and combustion heat technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of furnace body corrosion, long residence time, low combustion efficiency, etc., and achieve the effect of eliminating environmental pollution, fine particle size and high content of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

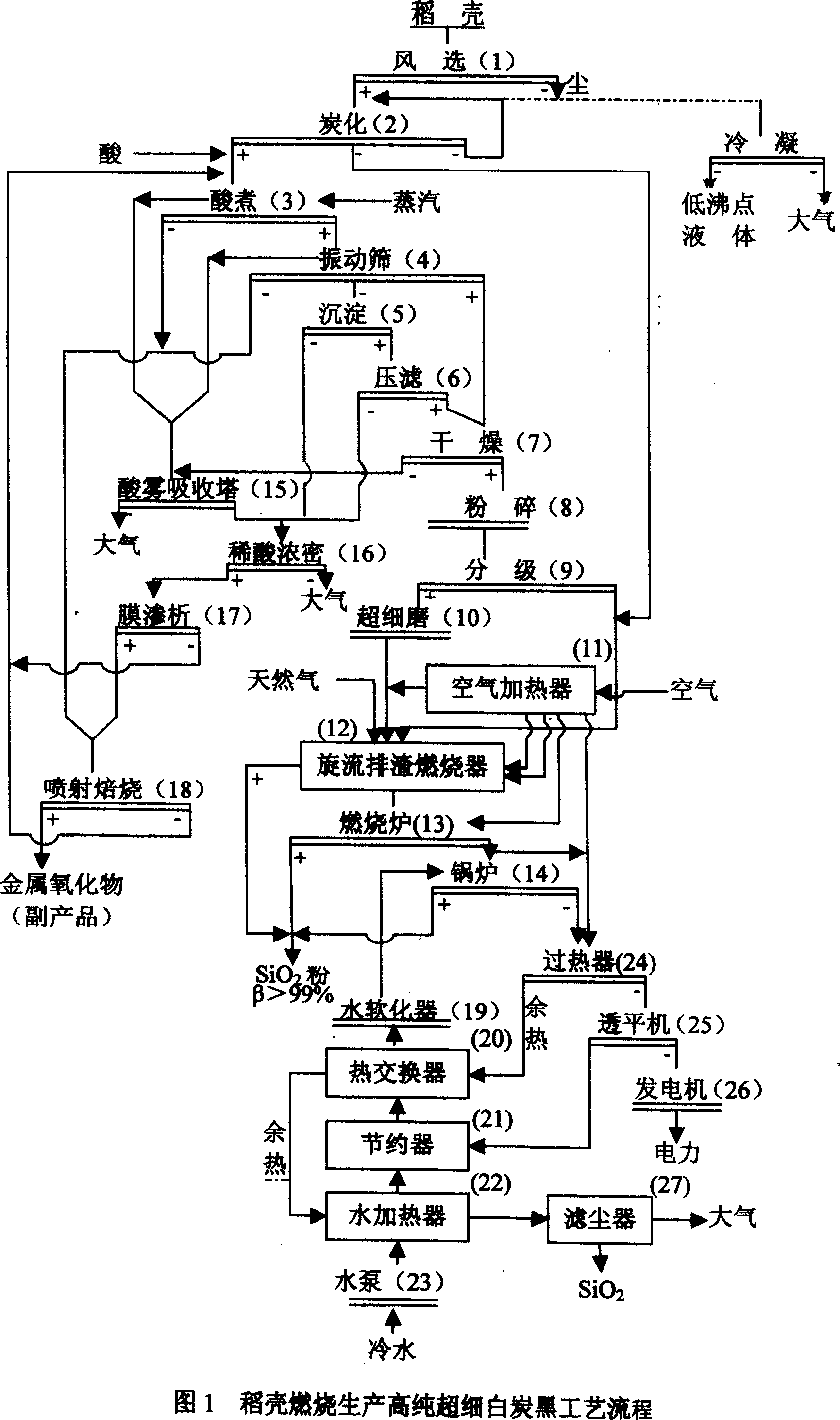

[0038] According to the main operation of the technological process shown in Figure 1, the rice husks taken from the Beijing rice mill were washed and dried, then carbonized and calcined at a temperature of 550 ° C for 1 hour, and 80% of volatile gas (not recovered); rice husk charcoal Boil with 6N hydrochloric acid at 120°C for 15min. It is deacidified on a vibrating sieve, washed with hot water until the pH value is neutral, dried, and pulverized by a high-speed vibrating mill to make a superfine powder. Air is blown into a tube-type electric furnace, and the suspended material is burned at a temperature of 1000°C to obtain SiO 2 A pure white product with a content of 99.37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com