Environment-friendly biomass granular fuel and preparation method thereof

A biomass particle and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low flash point, low burning value, easy agglomeration, etc., and achieve high combustion calorific value, lower cost and lower production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

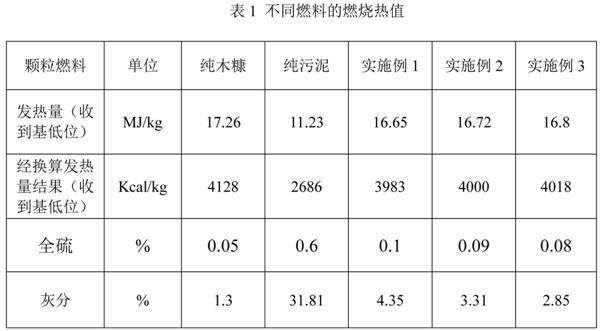

Embodiment 1

[0017] An environmentally friendly biomass granular fuel contains the following parts by weight: 80 parts of wood chaff, 9.5 parts of sludge and 1 part of waste oil.

[0018] The preparation method of above-mentioned environment-friendly biomass particle fuel, comprises the steps:

[0019] 1) Dry wood bran and sludge to a water content of 9.5%;

[0020] 2) Add waste oil to the treated wood chaff and sludge and stir evenly to obtain a mixture;

[0021] 3) Under the conditions of 180°C and 400MPa, process the mixture into cylindrical particles with a diameter of 8mm and a length of 30mm.

Embodiment 2

[0023] An environmentally friendly biomass granular fuel contains the following parts by weight: 83 parts of wood bran, 7 parts of sludge and 0.3 part of waste oil.

[0024] The preparation method of above-mentioned environment-friendly biomass particle fuel, comprises the steps:

[0025] 1) Dry wood bran and sludge to a water content of 9.7%;

[0026] 2) Add waste oil to the treated wood chaff and sludge and stir evenly to obtain a mixture;

[0027] 3) Under the conditions of 190°C and 380MPa, process the mixture into cylindrical particles with a diameter of 9mm and a length of 30mm.

Embodiment 3

[0029] An environmentally friendly biomass granular fuel contains the following parts by weight: 85 parts of wood bran, 5.5 parts of sludge and 0.5 part of waste oil.

[0030] The preparation method of above-mentioned environment-friendly biomass particle fuel, comprises the steps:

[0031] 1) Dry wood bran and sludge to a water content of 9%;

[0032] 2) Add waste oil to the treated wood chaff and sludge and stir evenly to obtain a mixture;

[0033] 3) Under the conditions of 200°C and 390MPa, process the mixture into cylindrical particles with a diameter of 10mm and a length of 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com