Joint production process of crude fuel hot charging and total heat oxygen blast furnace and vertical furnace

A technology of combined production and raw materials, applied in blast furnaces, shaft furnaces, blast furnace details, etc., can solve the problems of less bosh gas, poor pre-reduction of charge, and insufficient furnace heat in all-oxygen blast furnaces, so as to improve fuel utilization. , high emission, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

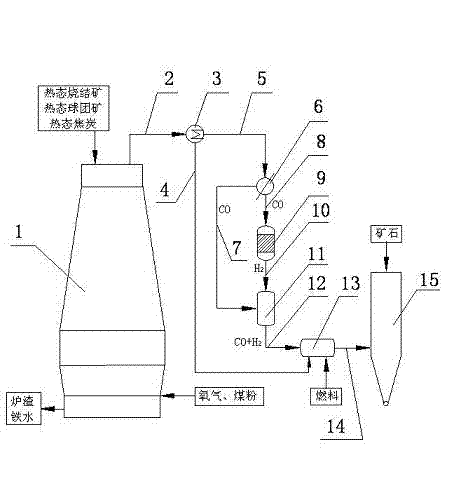

[0014] The combined production process of hot charging of raw materials and fuel, full thermal oxygen blast furnace and shaft furnace, the steps are:

[0015] 1) Preparations for raw material thermal charging, full thermal oxygen blast furnace and shaft furnace combined production system:

[0016] The combined production system of raw material and fuel hot charging, full thermal oxygen blast furnace and shaft furnace includes a blast furnace 1 and a gas-based shaft furnace 15; The input port is connected, the heat exchanger 3 (the heat exchanger 3 uses air as the heat exchange medium, the hot air from the heat exchanger 3 passes through the combustion air pipe 4 to the heater 13, and is used as combustion air, and the combustion air pipe 4 goes is the combustion-supporting air after heat exchange) the air output port is connected with the combustion-supporting air input port of the heater 13 by the combustion-supporting air pipe 4, and the blast furnace gas output port of the ...

Embodiment 2

[0029] Basically the same as Example 1, the difference is:

[0030] The hot charging temperatures of coke, sinter and pellets are 600°C, 700°C and 800°C respectively.

[0031] According to theoretical calculation, 3000m 3 The blast furnace uses pellets and sintered ore as raw materials, and 750°C pure oxygen (volume purity of more than 80%) is blown in from the tuyere. Its production technical indicators are as follows:

[0032] Oxygen consumption: 300Nm 3 / tHM,

[0033] Focal ratio: 150Kg / tHM,

[0034] Coal ratio: 370Kg / tHM,

[0035] Furnace top gas volume: 840Nm 3 / tHM,

[0036] Furnace top gas volume: 840Nm 3 / tHM,

[0037] Furnace top gas composition (volume): CO: 45.28%, CO 2 :35.75%, H 2 :8.35%, H 2 O: 7.1%, Others: 3.52%,

[0038] Shaft furnace fuel (volume) H 2 / CO:1.2:1,

[0039] Shaft furnace output: 750000t / a.

Embodiment 3

[0041] Basically the same as Example 1, the difference is:

[0042] The hot charging temperatures of coke, sinter and pellets are 800°C, 600°C and 700°C respectively.

[0043] According to theoretical calculation, 5000m 3 The blast furnace uses pellets and sintered ore as raw materials, and 850°C pure oxygen (volume purity of more than 80%) is blown in from the tuyere. Its production technical indicators are as follows:

[0044] Oxygen consumption: 290Nm 3 / tHM,

[0045] Focal ratio: 140Kg / tHM,

[0046] Coal ratio: 400Kg / tHM,

[0047] Furnace top gas volume: 820Nm 3 / tHM,

[0048] Top gas composition (volume): CO: 46.15%, CO 2 :33.75%, H 2 :8.35%, H 2 O: 9.1%, other 2.65%,

[0049] Shaft furnace fuel (volume) H 2 / CO: 1.1:1,

[0050] Shaft furnace output: 1200000t / a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com