Flat plate membrane filtering assembly

A technology of filtration components and flat membranes, applied in ultrafiltration, membrane technology, semi-permeable membrane separation, etc., can solve the problems of increasing operating costs, loss of filtration effect of filter membrane bags, clogging of filter membrane bags, etc., to achieve stable filtration water quality, Reduced operating costs and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing.

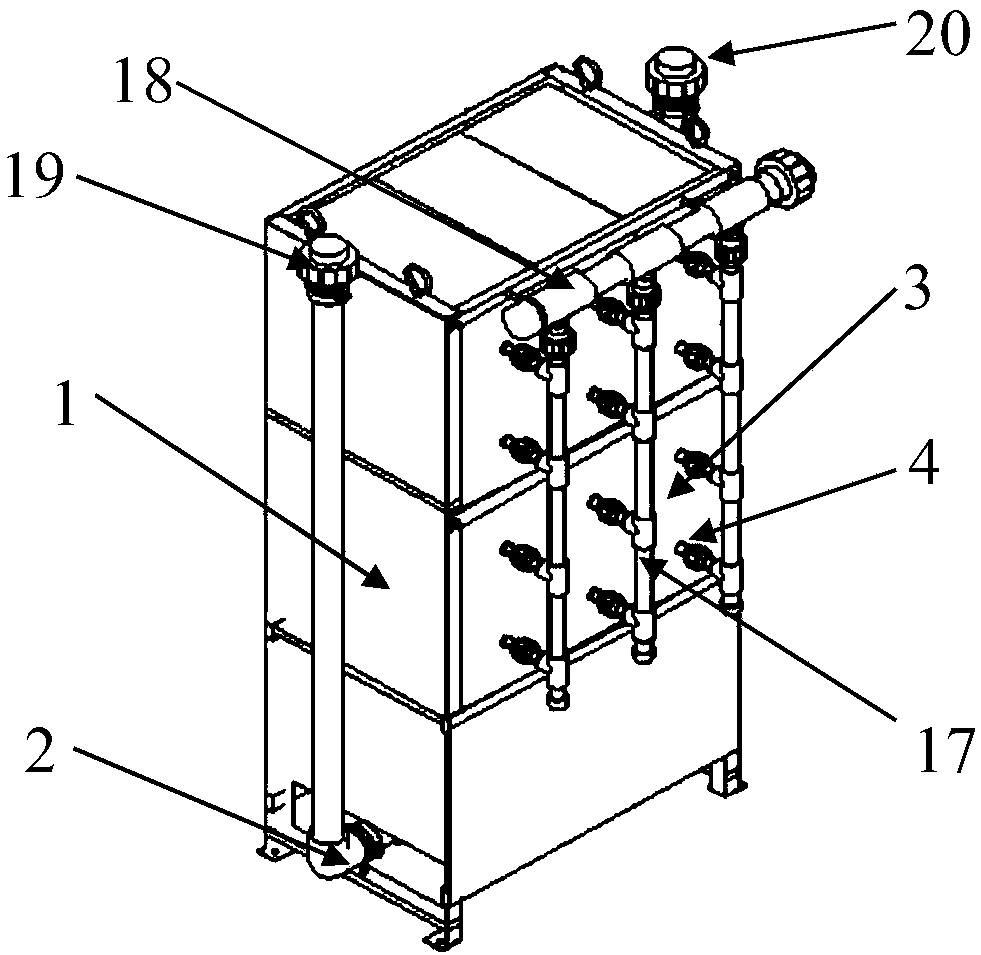

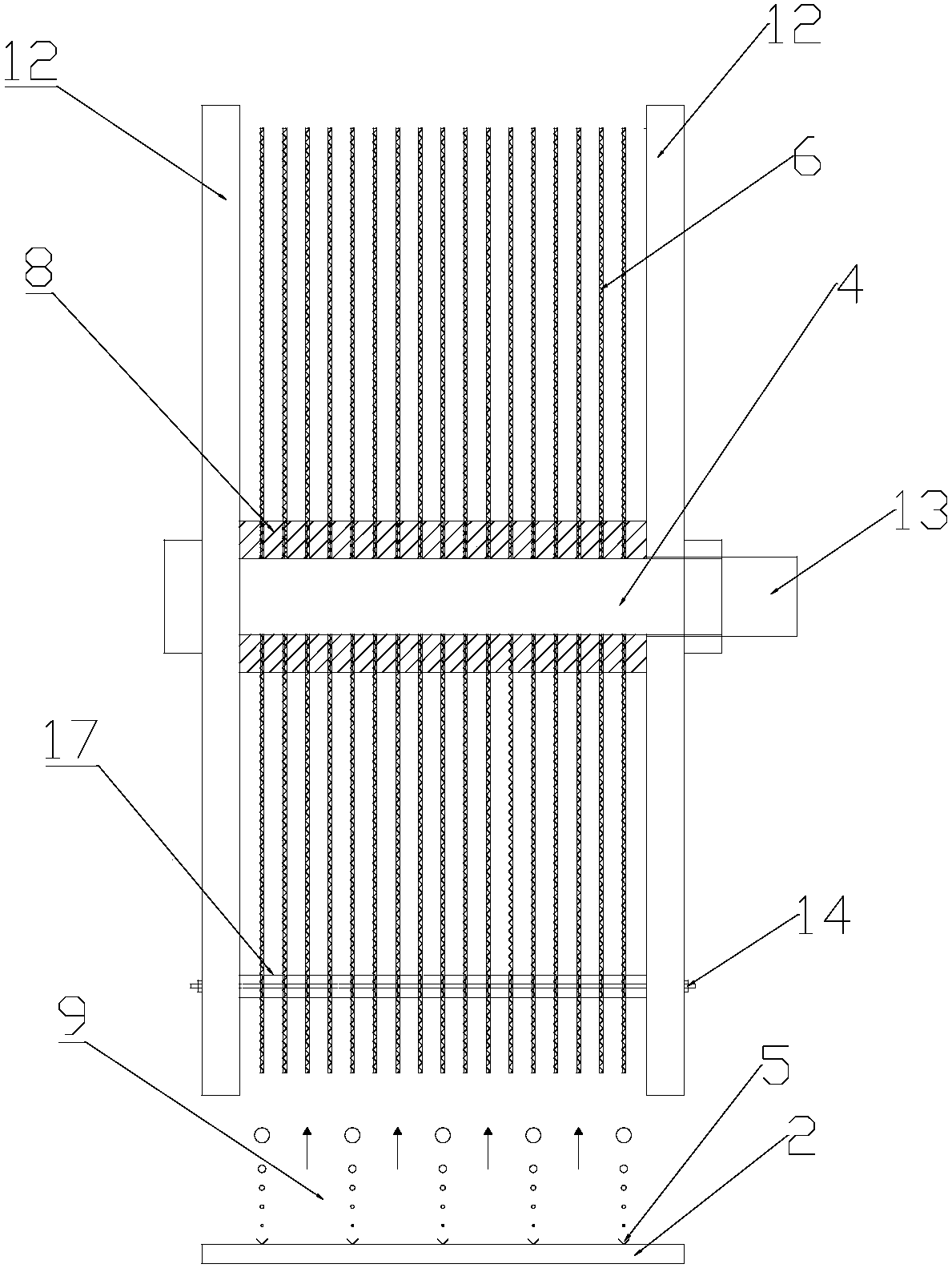

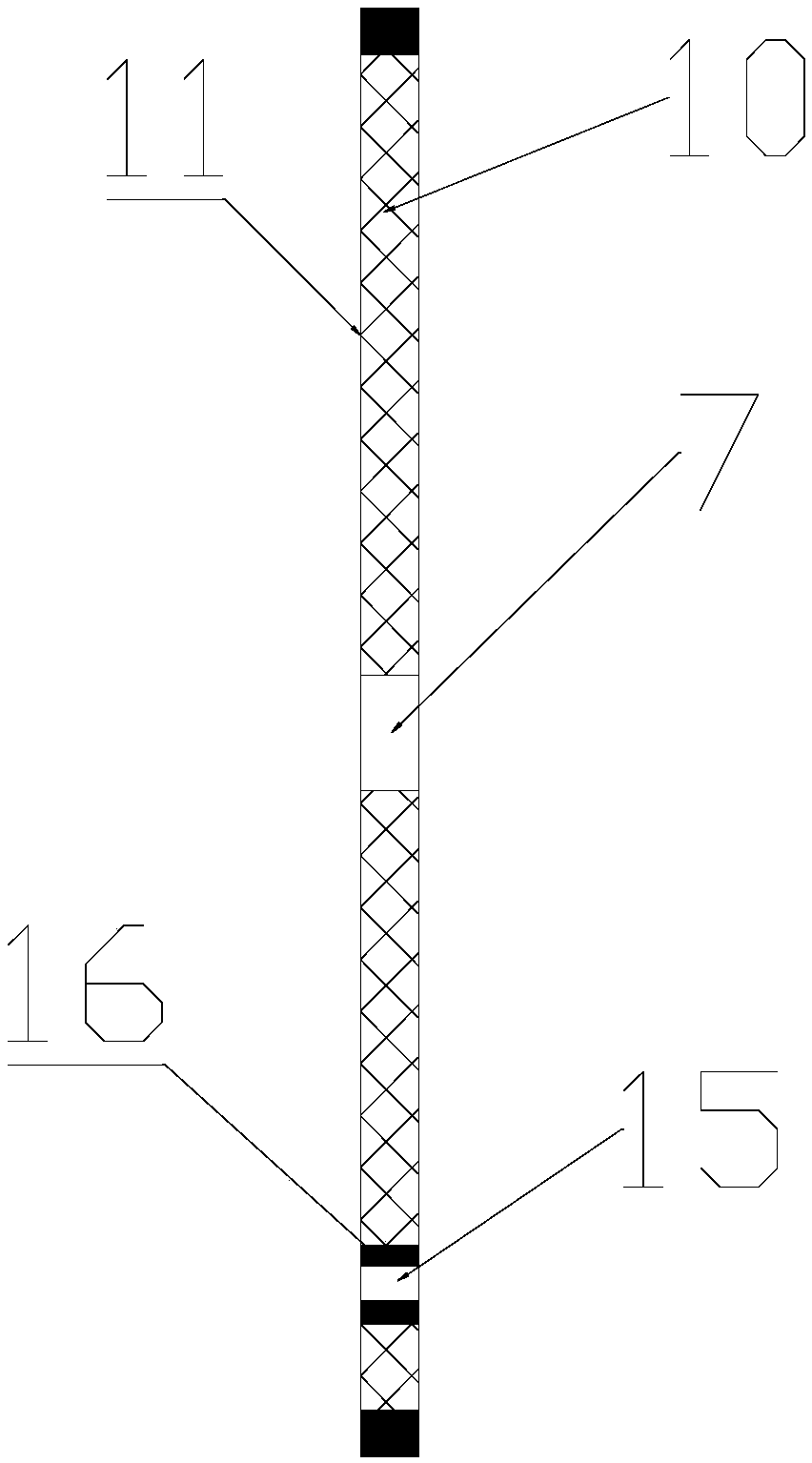

[0020] Such as Figure 1-3 As shown, a flat membrane filter assembly is characterized in that it includes a membrane box 1, an aeration tube 2 is installed at the bottom of the membrane box 1, and several membrane stacks 3 fixed in the membrane box 1 are arranged above the aeration tube 2 , the aeration pipe 2 is provided with a number of aeration holes 5 facing the membrane stack 3, each of the membrane stacks 3 includes a water collection pipe 4, and the water collection pipe 4 is provided with a number of flexible flat diaphragms 6, The flexible flat diaphragm 6 is provided with a through hole 7 for the water collecting pipe 4 to pass through, and the water collecting pipe 4 is provided with a drain hole connected to the inside of the flexible flat diaphragm 6 at the place where the flexible flat diaphragm 6 is sleeved. An upper sealing spacer ring 8 is arranged between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com