Mute air exhaust port of a roller type sand making machine

A technology of sand making machine and air outlet, which is applied in the direction of removing smoke and dust, grain processing, and separation of dispersed particles, etc., can solve the problems of adverse health effects of workers, dust easily inhaled by human body, and high dust filtration cost, and achieves good dust removal effect. , Easy to take out, easy to replace or clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

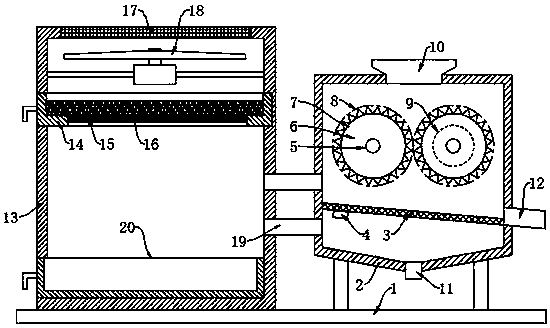

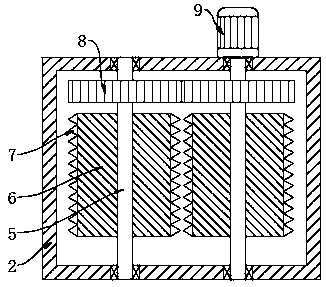

[0025] see Figure 1~2 , in an embodiment of the present invention, a silent exhaust outlet of a roller sand making machine includes a base 1, the top of the base 1 is respectively fixed with a crushing box 2 by brackets, and the top of the crushing box 2 is connected to a feed port The feeding hopper 10 is convenient for feeding; the front and rear directions of the crushing box 2 are provided with two left and right rotating shafts 5, and the front and rear ends of the rotating shafts 5 respectively pass through the front and rear side walls of the crushing box 2 and are connected in rotation with the front and rear side walls of the crushing box 2; 5 is fixedly installed with mutually cooperating crushing rollers 6, and the side walls of the crushing rollers 6 are also evenly distributed with a number of crushing teeth 7 to further improve the stone crushing effect; the rear ends of the left and right rotating shafts 5 are respectively fixedly installed with mutually meshing...

Embodiment 2

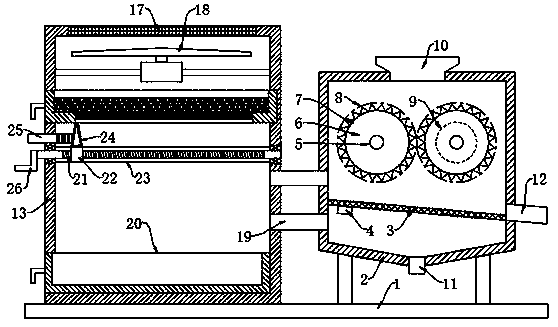

[0028] see image 3 , on the basis of Embodiment 1, a slider 22 is arranged below the first drawer 14 in the dust removal box 13, and a chute 23 cooperating with the slider 22 is provided on the front and rear side walls of the dust removal box 13, and the slider 22 slides left and right along the chute 23, the top of the slider 22 is fixedly connected with an air nozzle 24, and the air nozzle 24 faces the filter screen 15; Pass through the left side wall of the dust removal box 13 and be fixedly connected with the left side wall of the dust removal box 13. By drawing air from the telescopic tube 25, the dust attached to the bottom of the filter screen 15 can be sucked out of the dust removal box 13; There is also a screw 21 located below the first drawer 14. The left and right ends of the screw 21 respectively pass through the left and right side walls of the dust removal box 13 and are rotationally connected with the left and right side walls of the dust removal box 13 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com