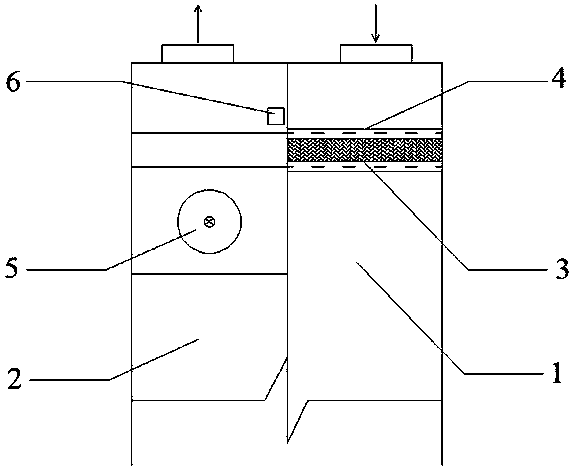

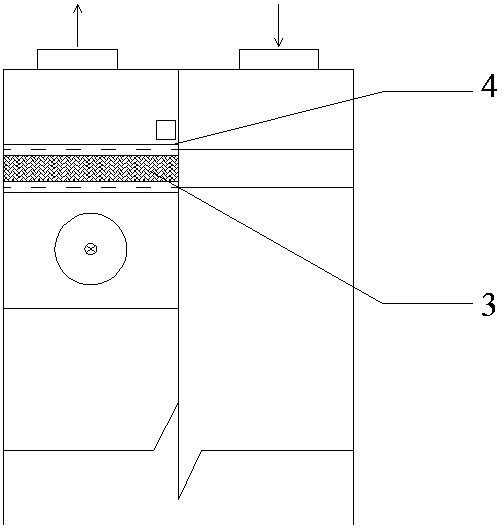

Self-cleaning device of dust filtering part and fresh air system

A self-cleaning, component-based technology, applied in ventilation systems, air-conditioning systems, transportation and packaging, etc., can solve the problems of inconvenient cleaning and replacement of dust filter devices, and the failure of fresh air systems to filter dust, etc., to improve convenience and cleanliness, and simple and convenient control , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

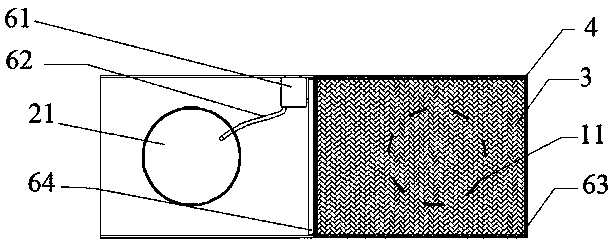

Embodiment 1

[0050] 1) Preparation method of non-woven fabric impregnated with quaternary ammonium salt solution:

[0051] The present invention selects the fiber average diameter as 60-100 μ m, gram weight as 20-50 g / m 2 Alginate fiber non-woven fabric with a thickness of at least 2mm, prepare a quaternary ammonium salt solution, the molar concentration of the solution is 0.1-0.3mol / L, immerse the non-woven fabric in the quaternary ammonium salt solution for 10-30min and take it out at 110-130°C Dry for 10-20min, that's it. The quaternary ammonium salt used is preferably octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, which has a good antistatic effect when used in conjunction with calcium alginate fiber non-woven fabrics. It is tested according to GB10064 at an air humidity of 40%. Under certain conditions, the surface resistance can reach 2.3×10 7 Ω. When octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate is used in conjunction with cotton fiber non-woven fabric...

Embodiment 2

[0057] 1) Filter preparation method:

[0058] Cut each layer of non-woven fabric, fiber net and sponge prepared by the above-mentioned method to a suitable size and shape, and heat press along the edge to obtain a filter net. The filter screen can be combined with the filter screen support by gluing; or the four sides of the filter screen can be bonded with magnetic components, the filter screen support is provided with magnetic components of opposite polarity, and the filter screen and the filter screen support are combined through magnetic components.

[0059] 2) The prepared filter has the property of effectively blocking dust and particulate matter and is easy to desorb dust and particulate matter. In the case of normal use for a week without dust removal or purging, the dust removal unit is not turned on, and the filter is only purged with normal wind for about 3 minutes. There is no visible dust or particle adsorption on the surface of the filter; After the filter is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com