Oxygen-poor heating type cigarette assembly

A heating-type, oxygen-deficient technology, which is applied in the fields of tobacco, e-liquid filter elements, and cigar manufacturing, and can solve problems such as increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An oxygen-poor heating smoking device, such as Figure 7 , Figure 4 , Figure 5 , Figure 11 and Figure 12 As shown: it includes a heating section (4), and there is a cigarette accommodating chamber (4-1) in the heating section (4), wherein, the oxygen-poor heating smoking appliance also includes a smoke extractor ( 2), the smoke extraction part (2) includes a hollow smoke extraction cone (2-1) and a fixed or detachable cone (2-1) sleeved on the smoke extraction cone (2-1) -2) the flue gas transmission pipe (2-2) on the periphery, the cone top and / or side wall of the hollow flue gas extraction cone (2-1) has a cone hole (2-1-4), the There is at least one through hole (2-2-2) on the circumferential side wall of the flue gas transmission pipe (2-2), and the axial distance from the through hole (2-2-2) to the bottom surface of the cone is smaller than that of the cone. The axial distance from the hole (2-1-4) to the bottom surface of the cone.

[0040] The bottom e...

Embodiment 2

[0048] A kind of oxygen-poor heating cigarette, such as Figure 8 Shown: comprising a tobacco segment (1) and a filter segment (3) detachably connected to each other, wherein one end face and / or a circumferential side of the tobacco segment (1) is sealed by an airtight foil.

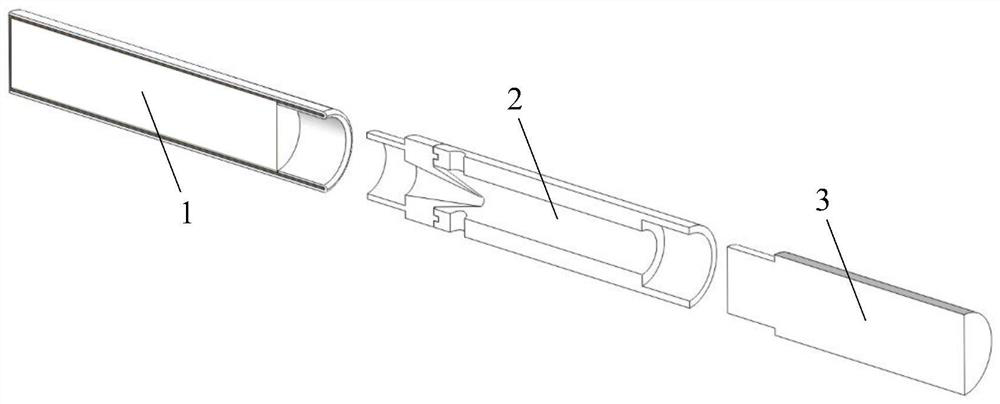

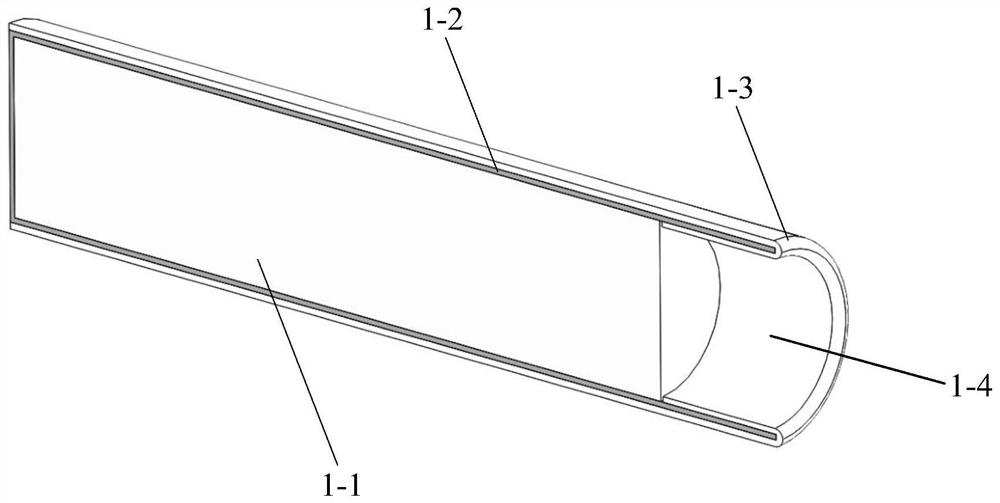

[0049] The unsealed end of the tobacco segment (1) has an axially extending unfilled segment (1-4) (see figure 2 , 3 ), said filter segment (3) has an exposed segment (3-1) not wrapped by tipping paper (3-2) (see Figure 6 ), the shapes of the unfilled section and the exposed section fit each other so that: when the tobacco section (1) and the filter section (3) are connected together, the exposed section (3-1) is inserted into the In unpopulated segments (1-4) (see image 3 , Figure 6 , Figure 8 ).

[0050] Preferably, the tobacco segment is conventional tobacco or a reconstituted tobacco leaf base.

[0051] Preferably, the length of the unfilled segment (1-4) of the tobacco segment is 3-5 mm,...

Embodiment 3

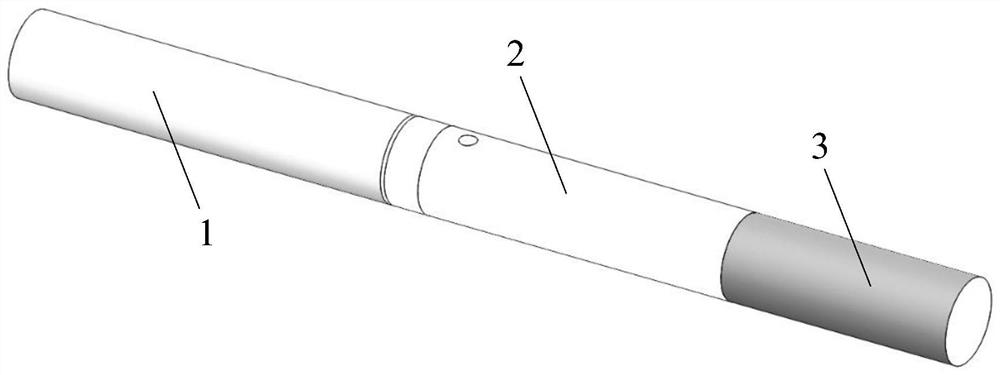

[0053] An oxygen-poor heated cigarette component, such as Figure 9 , Figure 10 Said, including the oxygen-deficient heating smoking device (B) and the oxygen-deficient heating cigarette (A).

[0054] from Figure 10 in and combined image 3 , Figure 5 , Figure 6 It can be clearly seen that the shape of the unfilled segment (1-4) of the tobacco segment (1) is also suitable for plugging with the sleeve segment (2-1-5) of the smoke extraction cone (2-1) , the shape of the exposed section (3-1) of the filter tip section (3) is also suitable for inserting with the 3 inner diameter enlarged sections (2-2-3) of the smoke transmission pipe (2-2) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com