Closed heating non-combustible cigarette and assembly

A heat-not-burn, closed-type technology, which is applied in the fields of tobacco, e-liquid filter elements, and cigar manufacturing, etc., and can solve problems such as the difficulty of smoke migration in closed-type cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

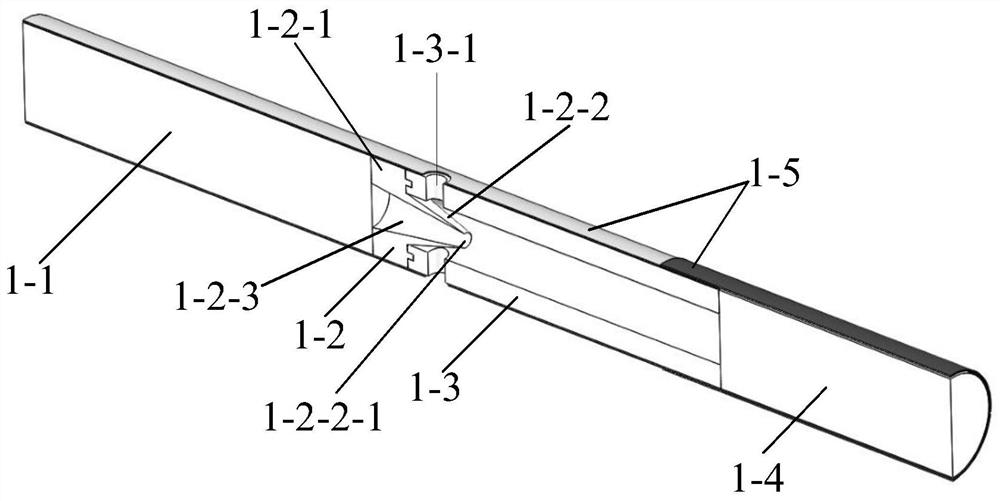

[0038] A closed heat-not-burn cigarette, comprising a tobacco rod (1-1), a hollow smoke extraction cone (1-2), a smoke transmission pipe (1-3), a functional filter (1-4) and an outer Coil material (1-5). Among them, the tobacco rod (1-1), the hollow smoke extraction cone (1-2), the smoke transmission pipe (1-3), and the functional filter tip (1-4) are sequentially contacted, and are wound by the external material ( 1-5) Parcel. (Such as Figure 4 shown)

[0039] The circumference and / or upstream end surface of the tobacco rod (1-1) is wrapped with an airtight or controllable air permeability paper-based or foil-based material to form a closed system.

[0040] The hollow flue gas extraction cone (1-2) includes a cylindrical base (1-2-1) and a tapered cone (1-2-2), and has a tapered cavity (1- 2-3) (such as image 3 shown); the taper cone (1-2-2) has a conical hole (1-2-2-1) on the cone top and / or side wall (as image 3 , Figure 5 , Figure 6 and Figure 9 shown).

[...

Embodiment 2

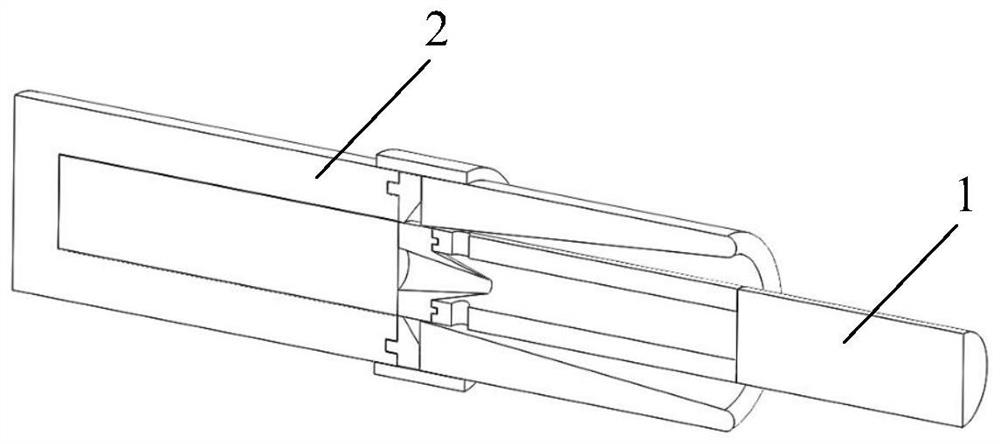

[0049] A sealed heat-not-burn cigarette assembly, comprising the above-mentioned sealed heat-not-burn cigarette and a sealed heat-not-burn cigarette set (2).

[0050] The closed heating smoking appliance (2) includes a heating section (2-1), and the heating section (2-1) includes a cigarette accommodating cavity (2-1-1). (Such as Figure 7 , Figure 8 shown)

[0051] A heating element (2-1-2) is provided on the circumferential side wall and / or bottom surface of the cigarette accommodating cavity (2-1-1) (such as Figure 7 As shown), when the sealed heat-not-burn cigarette is inserted, it wraps the tobacco rod completely in the circumferential direction.

[0052] The airtight heating smoking appliance (2) further includes a cap (2-3), and the cap (2-3) and the heating segment (2-1) are directly and detachably connected to each other or through a sealing ring (2- 2) To achieve detachable connection, the cap (2-3) has a gradually expanding inner cavity (2-3-1). (Such as Fi...

Embodiment 3

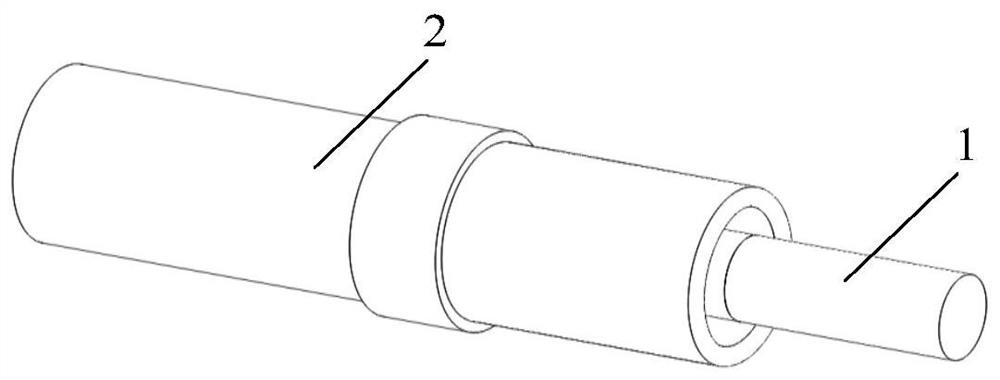

[0058] The method of use of the present invention is as figure 1 , figure 2 As shown, the specific process is as follows: First, remove the cap of the heating device, insert a closed heat-not-burn cigarette, then replace the cap and lock it, and start heating while locking the cap. When inhaling, the air first enters the space between the cap and the cigarette, and then enters the inside of the smoke delivery tube through the through hole on the smoke delivery tube of the closed heat-not-burn cigarette and sprays to the surface of the extraction cone. Due to the Venturi effect and The Coanda effect will form a negative pressure at the cone hole; the heating of the tobacco rod will form a positive pressure on the tobacco rod; the existence of positive and negative pressure difference and smoke concentration difference will lead to the active diffusion of smoke, so the smoke It flows out from the cone hole and enters the oral cavity through the lumen of the smoke transmission ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com