Cooling tower water vapor and heat energy recovery method and system

A heat recovery and cooling tower technology, applied in the direction of water shower coolers, heat exchanger types, lighting and heating equipment, etc., to achieve the effect of large control range, good atomization of water flow, and avoid direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

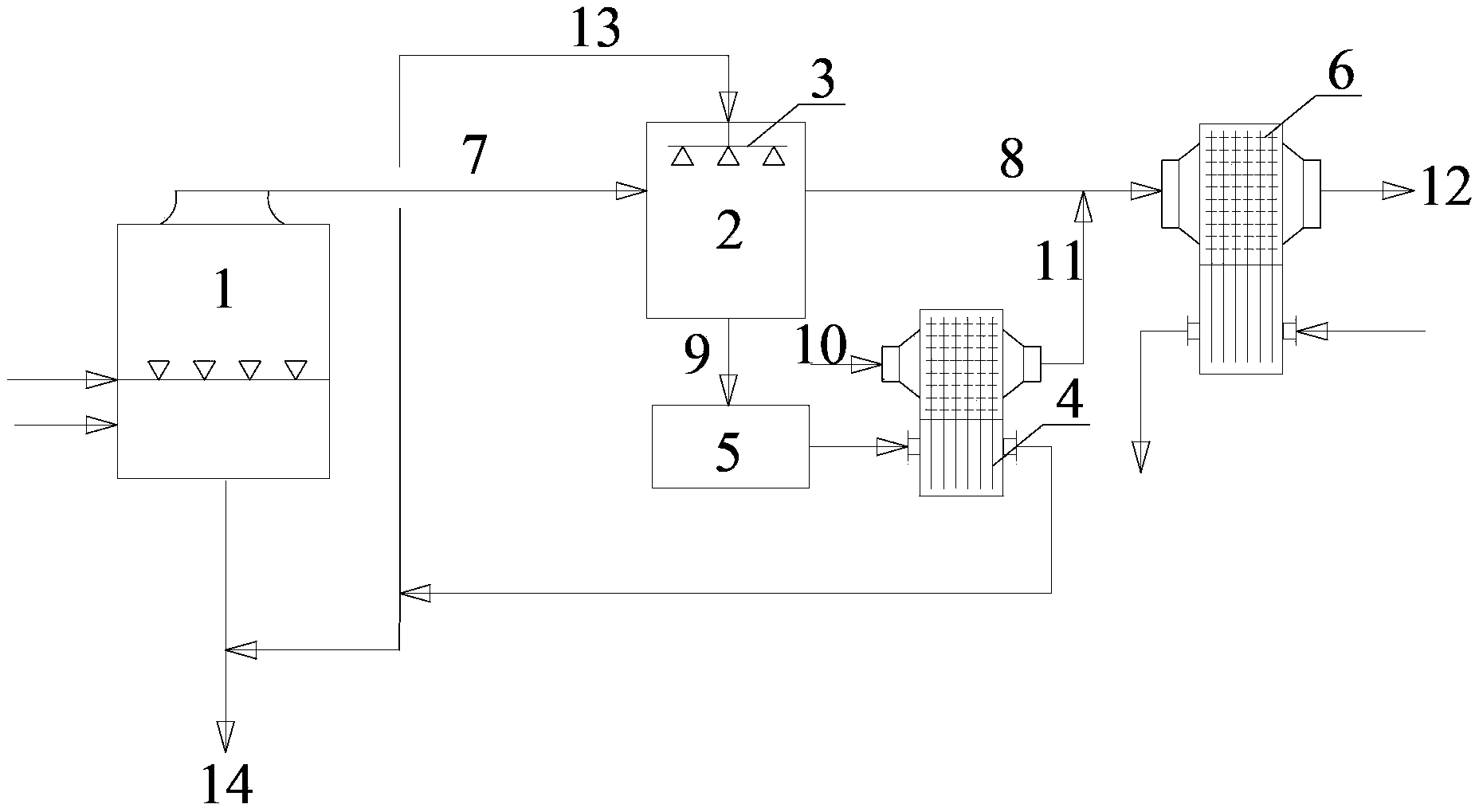

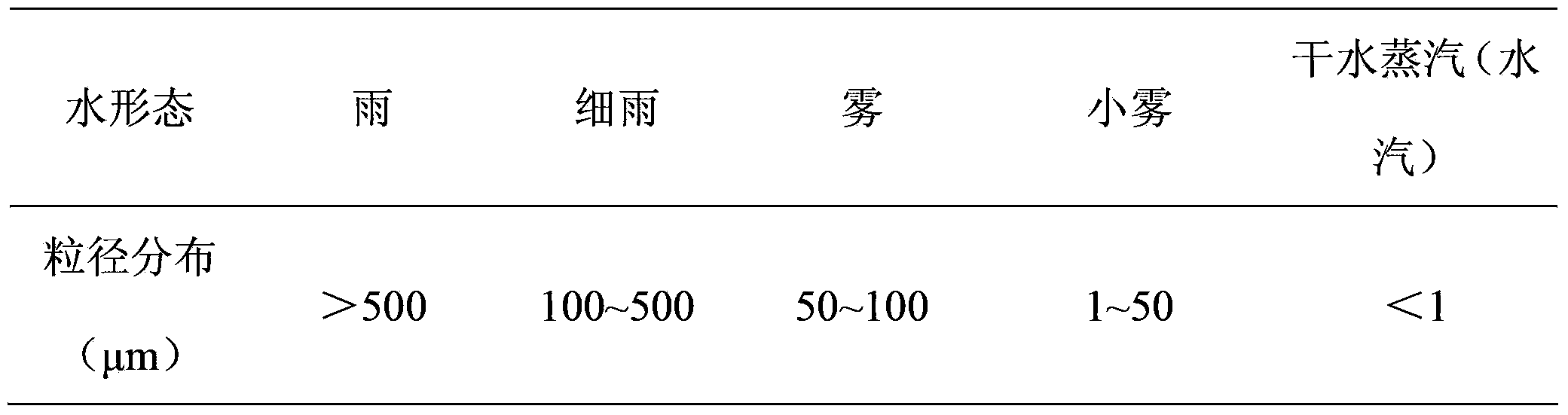

[0057] A cooling tower water vapor and heat energy recovery method, the method introduces the water vapor discharged from the cooling tower 1 into the condenser 2; in the condenser 2, the condensing agent water is atomized into fine particles, sprayed on the water vapor, and the water vapor Condensed into water when condensed, the air is discharged from the condenser 2 in a dry and hot state.

[0058] The condensed water formed in the condenser 2 transfers its heat energy to the dry hot air discharged from the condenser 2 through heat exchange; or, preheats other gases or liquids that need to be heated.

[0059] The thermal energy of the hot and dry air discharged from the condenser 2 is recovered to form dry and cold air for discharge or return to the cooling tower 1 for air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com