Preparing device and method for forming micro-nanofiber

A micro-nano fiber and preparation device technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve problems such as inability to effectively obtain synchronization, obstruction of micro-nano fibers, and inability to prepare fibers of different diameters at the same time, to achieve improvement Yield and diameter preparation problems, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 3g of polyvinyl alcohol, dissolve it in 27g of ultrapure water, and stir magnetically at 150°C for 30 minutes to obtain a transparent solution; then add 0.06g of sodium chloride and stir magnetically at 150°C for 20 minutes to obtain a pure spinning solution.

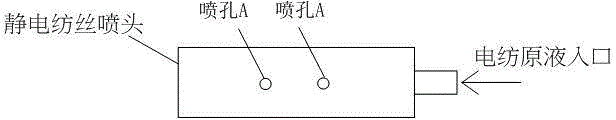

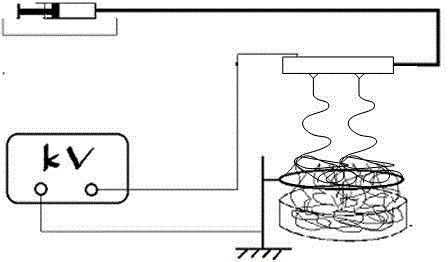

[0038] Inhale the prepared pure spinning liquid into 5mL syringes respectively, and connect the syringes to the two-hole electrospinning nozzles with the same diameter orifice device ( figure 1 shown). Connect the positive side of the high voltage power supply to the needle and the negative side to the ferrule. Adjust the flow rate of the two syringe pumps to 0.15mL / h and the receiving distance to 4cm, then turn on the high-voltage power supply and set the voltage to 15kV to collect electrospun fibers with a double yield ( figure 2 shown).

Embodiment 2

[0040] Weigh 3g of polyvinyl alcohol, dissolve it in 27g of ultrapure water, and stir magnetically at 150°C for 30 minutes to obtain a transparent solution; then add 0.06g of sodium chloride and stir magnetically at 150°C for 20 minutes to obtain a pure spinning solution.

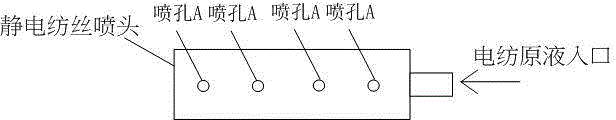

[0041] The prepared pure spinning solution was sucked into a 5mL syringe respectively, and the syringe was connected to a four-hole electrospinning nozzle with the same diameter orifice device ( image 3 shown). Connect the positive side of the high voltage power supply to the needle and the negative side to the ferrule. Adjust the flow rate of the two syringe pumps to 0.25mL / h and the receiving distance to 4cm, then turn on the high-voltage power supply and set the voltage to 18kV to collect electrospun fibers with 4 times the yield ( Figure 4 shown).

Embodiment 3

[0043] Weigh 3 g of polyvinyl alcohol, dissolve it in 27 g of ultrapure water, and stir it magnetically at 150° C. for 30 min to obtain a pure spinning solution.

[0044] Inhale the prepared pure spinning liquid into 5mL syringes respectively, and connect the syringes to the four-hole electrospinning nozzles with different diameter nozzles through silicone tubes ( Figure 5 shown). Connect the positive side of the high voltage power supply to the needle and the negative side to the ferrule. Adjust the flow rate of the two syringe pumps to 0.1mL / h and the receiving distance to 6cm, then turn on the high-voltage power supply and set the voltage to 18kV to collect electrospun fibers with different diameters at the same time ( Figure 6 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com