Micro-nano scale 3D printer and method

A 3D printer and micro-nano-scale technology, which is applied to 3D object support structures, manufacturing tools, coating devices, etc., can solve the problems of single printing materials, difficulty in printing, and low resolution, so as to ensure manufacturing accuracy and scale Broad, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

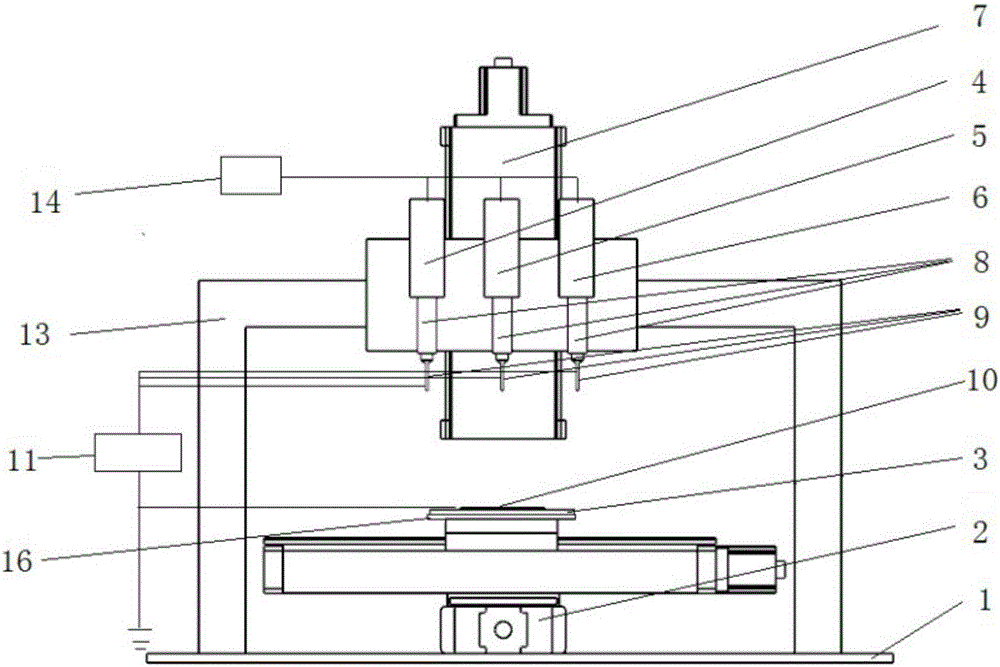

[0043] Such as figure 1 As shown, the micro-nano-scale 3D printer includes: a base 1, an x-y table 2, a film holder 3, a first nozzle 4, a second nozzle 5, a third nozzle 6, a z-direction table 7, a syringe 8, Conductive nozzle 9, substrate 10, high voltage power supply 11, frame 13, pressure pipeline 14, camera 15, heating pad 16. The base 1 is placed at the bottom; the x-y workbench 2 is placed on the base 1; the printing bed 3 is fixed on the x-y workbench 2; the first nozzle 4, the second nozzle 5 and the third nozzle 6 are respectively placed on the support platform 3 Directly above, and connected with the z-direction workbench 7; the z-direction workbench 7 is fixed on the beam 1301 of the frame 13; the frame 13 is fixed on the base 1; the first nozzle 4, the second nozzle 5 and the third nozzle 6. Air inlets are arranged respectively, and the air inlets are all connected to the pressure pipeline 14 through flexible pipes. A high-voltage power supply 5 is provided betw...

Embodiment 2

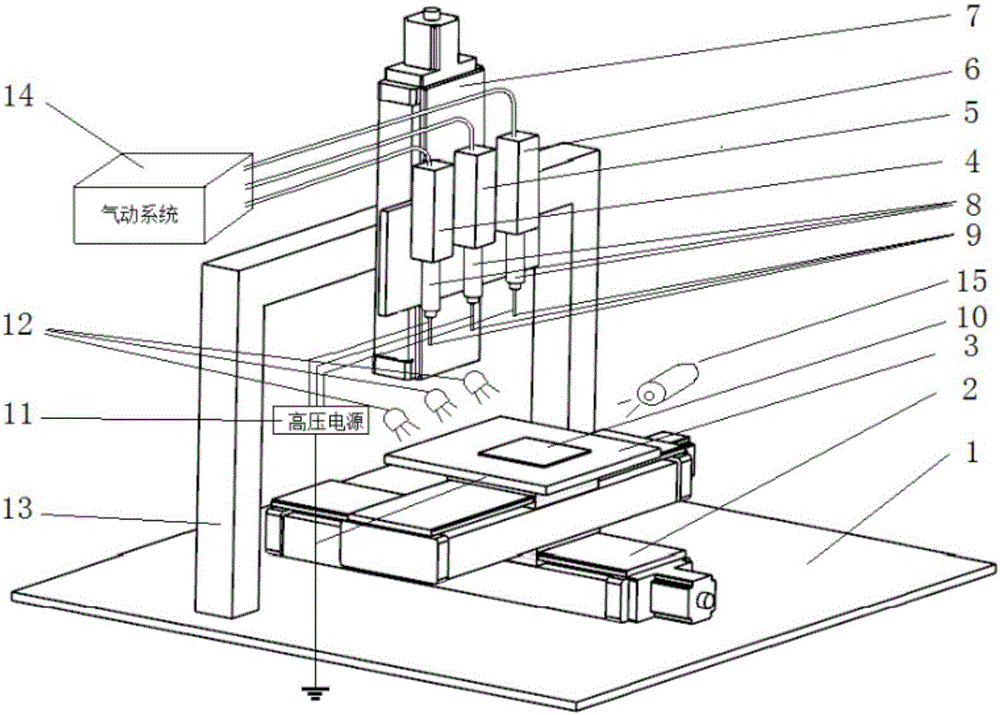

[0052] Such as figure 2 As shown, the micro-nano-scale 3D printer includes: base 1, x-y table 2, film holder 3, first nozzle 4, second nozzle 5, third nozzle 6, z-direction table 7, syringe 8, conductive nozzle 9. Substrate 10, high voltage power supply 11, UV curing light source 12, frame 13, pressure pipeline 14, camera 15. The base 1 is placed at the bottom; the x-y workbench 2 is placed on the base 1; the printing bed 3 is fixed on the x-y workbench 2; the first nozzle 4, the second nozzle 5 and the third nozzle 6 are respectively placed on the support platform 3 Directly above, and connected with the z-direction workbench 7; the z-direction workbench 7 is fixed on the beam 1301 of the frame 13; the frame 13 is fixed on the base 1; the first nozzle 4, the second nozzle 5 and the third nozzle 6. Air inlets are arranged respectively, and the air inlets are all connected to the pressure pipeline 14 through flexible pipes. A high-voltage power supply 5 is provided between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com