Electrostatic spinning device and cleaning method of electrostatic spinning nozzle of electrostatic spinning device

A technology of electrospinning and nozzle, which is applied in the direction of spinneret assemblies, textiles and papermaking, filament/thread forming, etc. It can solve the problems of easy clogging of spinning nozzles, and achieve convenient practical application, low spinning voltage, Easy and convenient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

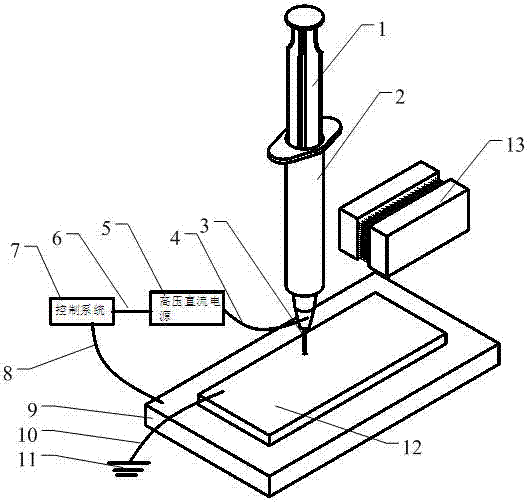

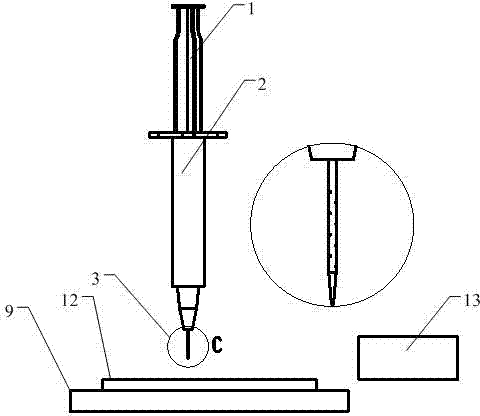

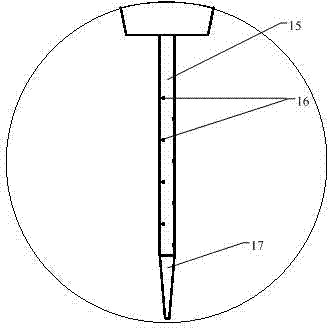

[0024] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, the electrospinning device of the present invention includes a syringe pushing mechanism 1, a syringe 2, an electrospinning nozzle 3, a high-voltage direct current power supply 5, a control system 7, a motion platform 9, a collector 12, and a syringe 2 Installed on the motion platform 9 that can realize the movement of the spinning process, the syringe pushing mechanism 1 is installed on one end of the syringe 2, the electrospinning nozzle 3 is installed on the other end of the syringe 2, and the syringe pushing mechanism 1 is under the action of force. The solution in the syringe 2 is extruded from the electrospinning nozzle 3, the high-voltage DC power supply 5 is connected to the electrospinning nozzle 3 through the wire 4, and the conductive collector 12 is connected to the earth electric field 11 through the wire 10. Next, a high-voltage electric field is formed between the collector 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com