Electrostatic spinning device and method for mass nanometer/micrometer fibers

A micro-fiber, electrospinning technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as low production efficiency, inability to achieve large-scale production, etc., to improve production efficiency and promote production efficiency , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

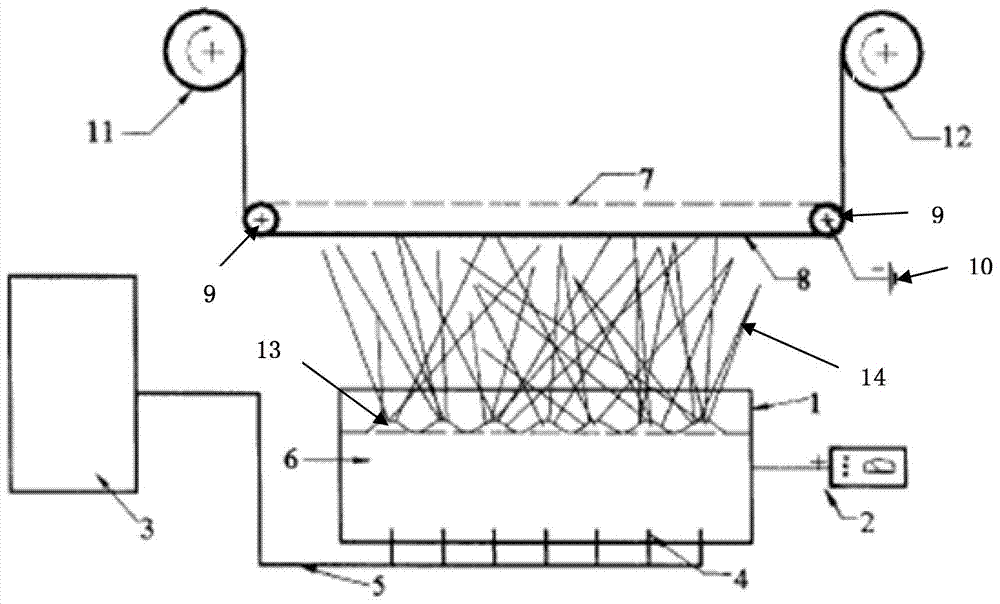

[0046] figure 1 It is a schematic structural diagram of the nano / micro electrospinning device in the first embodiment of the present invention;

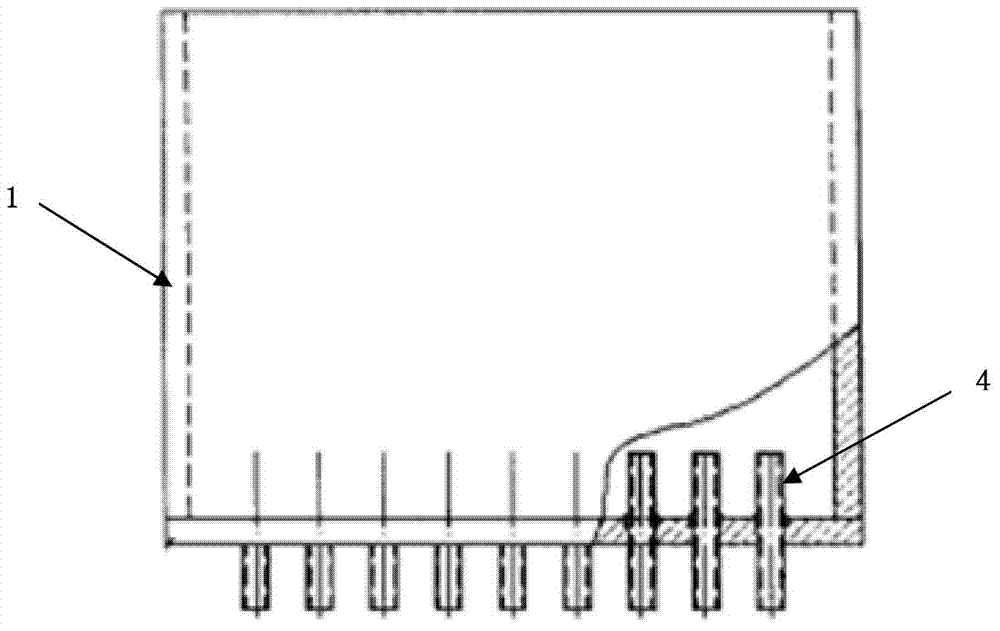

[0047] figure 2 It is a partial sectional view of the arrangement structure of the air nozzles in the nano / micro electrospinning device according to the first embodiment of the present invention;

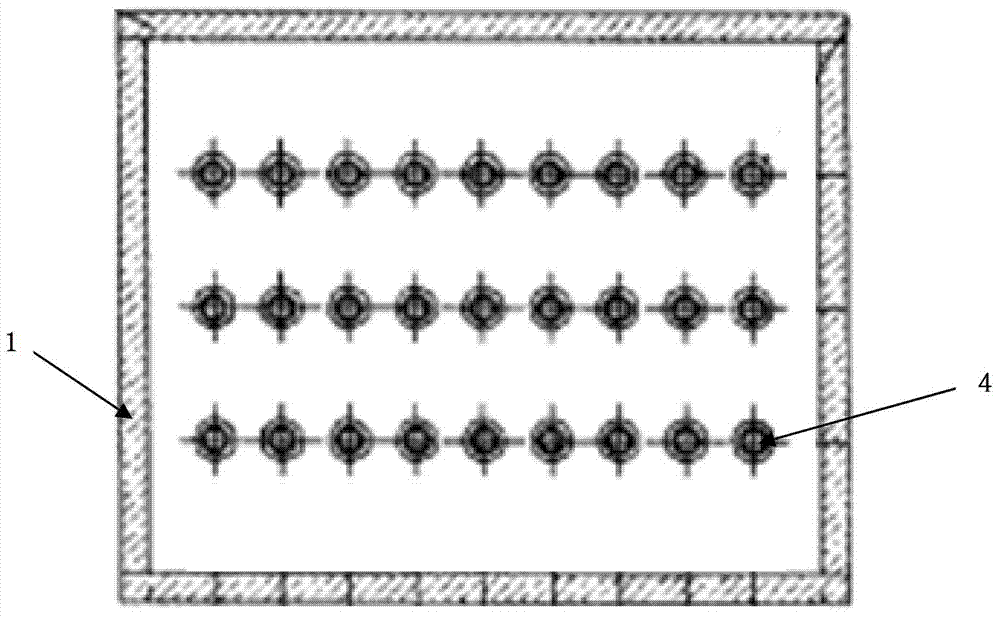

[0048] image 3 It is a top view of the arrangement structure of the air nozzles in the nano / micro electrospinning device in the mode of the first embodiment of the present invention.

[0049] The embodiment of the present invention discloses a large-volume electrospinning device for nano / micro fibers, which includes:

[0050] a reservoir having an upper opening for containing polymer fluid;

[0051] A bubble generating device and a high-voltage electrostatic generator coupled to the polymer fluid in the liquid storage tank, the bubble generating device acts on the polymer fluid in the liquid storage tank, so that the liquid surface o...

no. 1 example approach

[0086] see figure 1 , figure 1 For the attached figure 1 It is a schematic structural diagram of the nano / micro electrospinning device in the first embodiment of the present invention; figure 1 A large amount of electrospinning device for nano / micro fibers shown, including:

[0087] A liquid storage tank 1 with an upper opening is used to accommodate a polymer fluid 6, and the polymer fluid 6 can be a solution or a melt;

[0088] A bubble generating device coupled with the polymer fluid 6 in the liquid reservoir 1 and a high-voltage electrostatic generator 2, wherein the bubble generating device includes an air pump 3 and an air guide tube 5 connected to the air pump 3, and the air guide tube There are 27 air nozzles 4 on the

[0089] see figure 2 and image 3 , figure 2 It is a partial cross-sectional view of the arrangement structure of the air nozzles in the nano / micro electrospinning device according to the first embodiment of the present invention, image 3 It is ...

no. 2 example approach

[0105] You can also refer to the first embodiment figure 1 , figure 2 and image 3 As shown in the nano / micro electrospinning device, the difference between the nano / micro electrospinning device of the second embodiment and the first embodiment is that the air duct is provided with 49 air nozzles, and the The 49 air nozzles are arranged in a matrix with 7 rows and 7 columns; the rest of the structure and connection relationship of the second embodiment are the same as the first embodiment.

[0106] The nano / micro electrospinning method of the second embodiment is different from the first embodiment only in that: the distance between the negative electrode collecting device and the polymer fluid surface is 50 cm, and the air flow output by the air pump The flow rate is 50m / s, and the output voltage of the high-voltage electrostatic generator is adjusted to 30KV; the rest of the steps are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com