Electro-spray ion generator

An electrospray ion and generator technology, which is applied in the field of analytical instruments, can solve the problem that the ion transmission efficiency is not significantly improved, and achieve the effects of stable ion emission and high ion transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

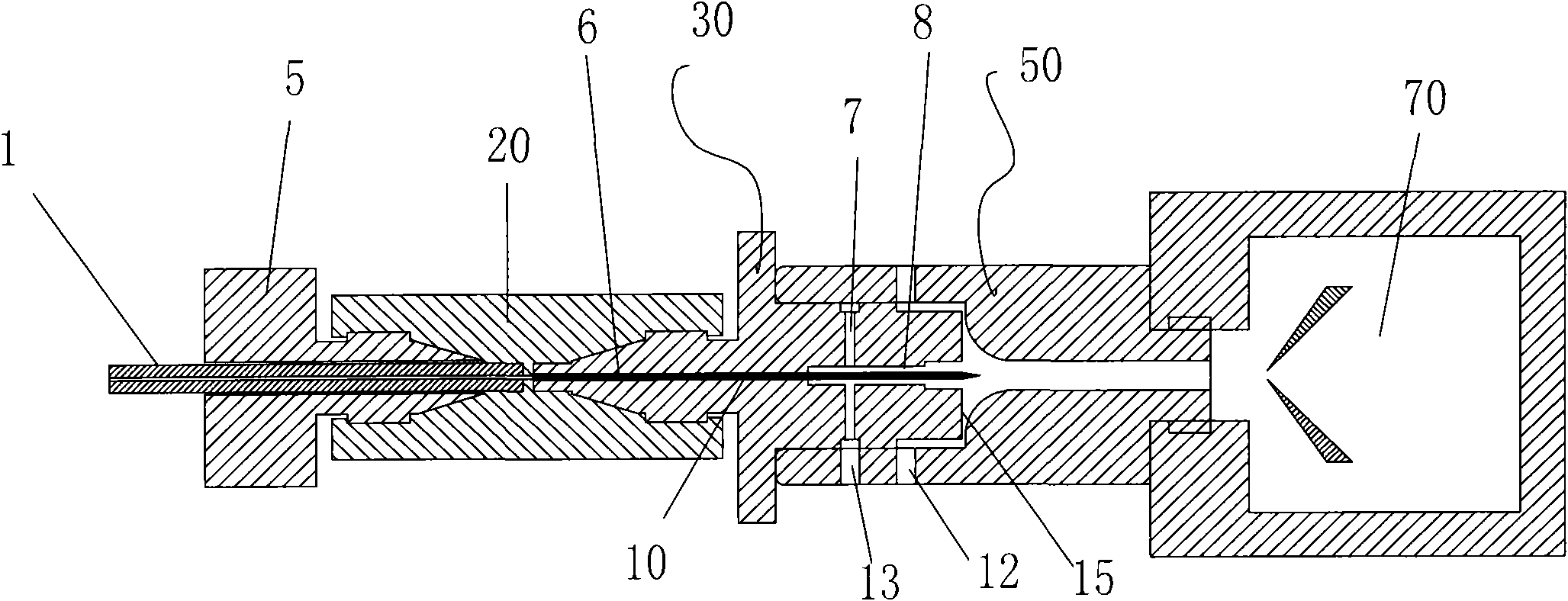

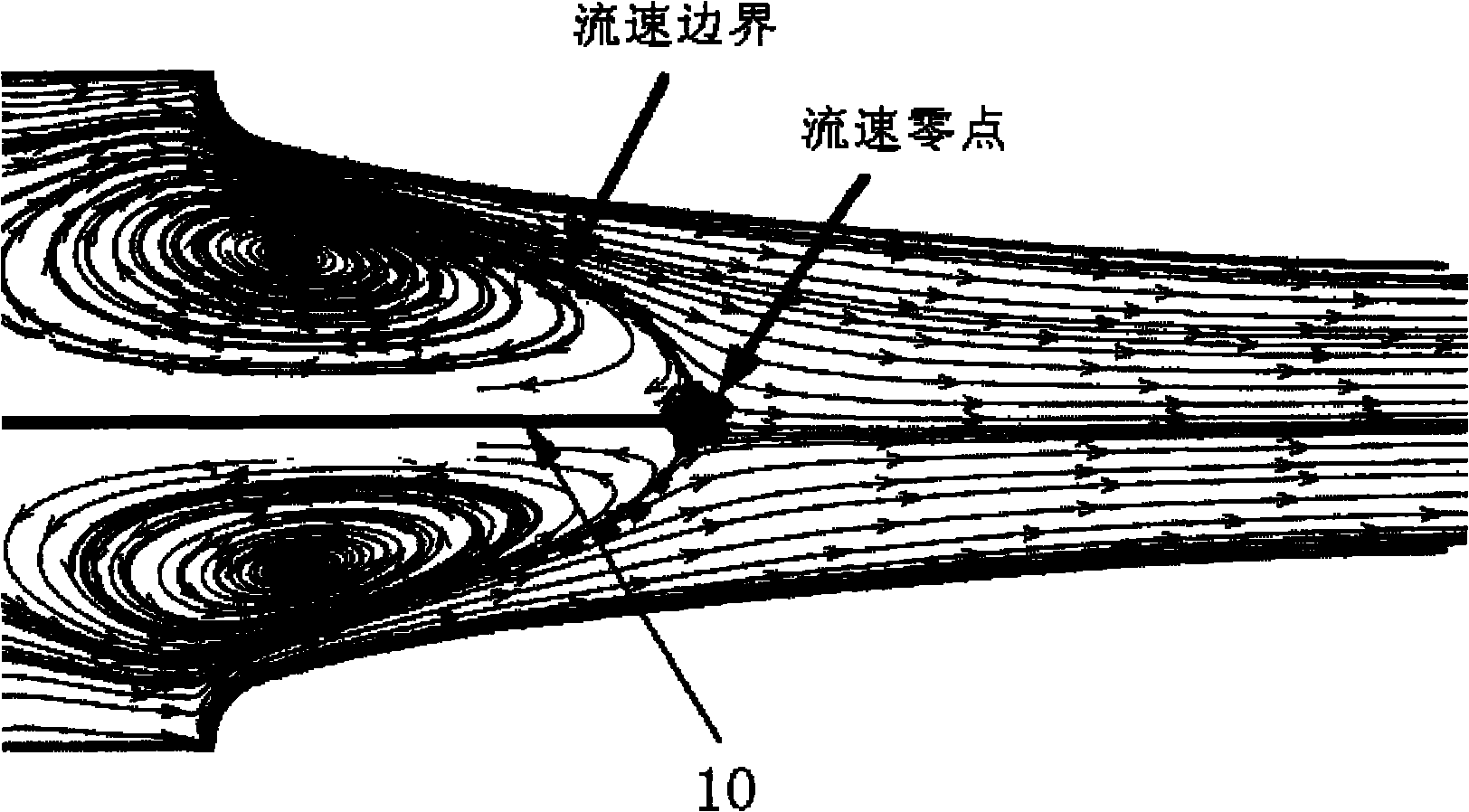

[0039] according to figure 1 , figure 2 , Figure 4 , Figure 5As shown in the structure, an electrospray ion generator is made, which includes a hollow capillary emitting needle 10, a high-voltage electrical connector 20, a hollow capillary emitting needle support 30, and one end of the fixing block 5 is located at the front section of the high-voltage electrical connector 20 cavity. And there is a through hole in the middle of the fixed block 5; the liquid chromatography connecting pipe 1 passes through the through hole in the fixed block 5, and is fixed in the high-voltage electrical connector 20, and the outer wall of the liquid chromatography connecting pipe 1 and the fixed block 5 The inner wall of the through hole is closely matched; the vacuum introduction capillary 50 and the high-voltage electrical connector 20 are matched and connected through the hollow capillary emitting needle bracket 30, and one end of the hollow capillary emitting needle bracket 30 is embedd...

Embodiment 2

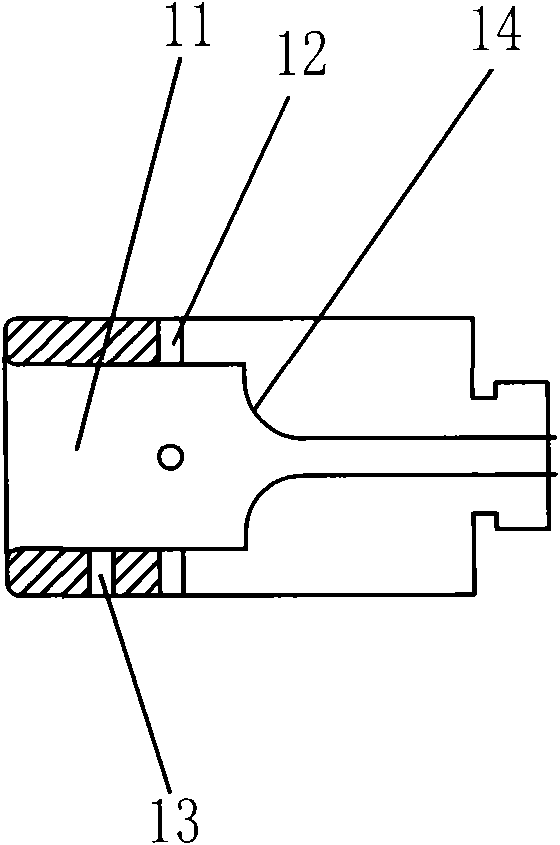

[0048] Adopt the same structure as embodiment 1, have the auxiliary hole 12 to the side of the vacuum introduction capillary 50 wherein, the auxiliary hole 12 is connected with the cavity 11; There are 4 auxiliary holes 12 on the side of the vacuum introduction capillary 50, the auxiliary hole 12 The inner gas is nitrogen; the tip of the hollow capillary emitting needle 10 exceeds the end face 15 of the hollow capillary emitting needle support 30 to be 2 millimeters; the hollow capillary emitting needle 10 is a hollow glass capillary; the vacuum leading capillary 50 is a metal material, and then the hollow capillary The emission needle 10, the vacuum introduction capillary 50, the liquid chromatography connection tube 1, the vacuum introduction capillary 50, the high voltage electrical connector 20, and the hollow capillary emission needle support 30 are on the same axis; the rear end cavity of the hollow capillary emission needle support 30 8 diameters are 1.3 times of the dia...

Embodiment 3

[0050] Adopt the same structure as embodiment 1, have the auxiliary hole 12 to the side of the vacuum introduction capillary 50 wherein, the auxiliary hole 12 is connected with the cavity 11; There are 8 auxiliary holes 12 on the side of the vacuum introduction capillary 50, the auxiliary hole 12 The internal gas is air; the tip of the hollow capillary emitting needle 10 exceeds the end face 15 of the hollow capillary emitting needle support 30 by 5 millimeters; the hollow capillary emitting needle 10 is a hollow metal capillary; the vacuum introduction capillary 50 is made of ceramic material, and then Put the hollow capillary launch needle 10, the vacuum introduction capillary 50, the liquid chromatography connection tube 1, the vacuum introduction capillary 50, the high voltage electrical connector 20, and the hollow capillary launch needle support 30 on the same axis; The diameter of the end cavity 8 is 1.4 times of the diameter of the hollow capillary emission needle 10; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com