Patents

Literature

43 results about "Porous media flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

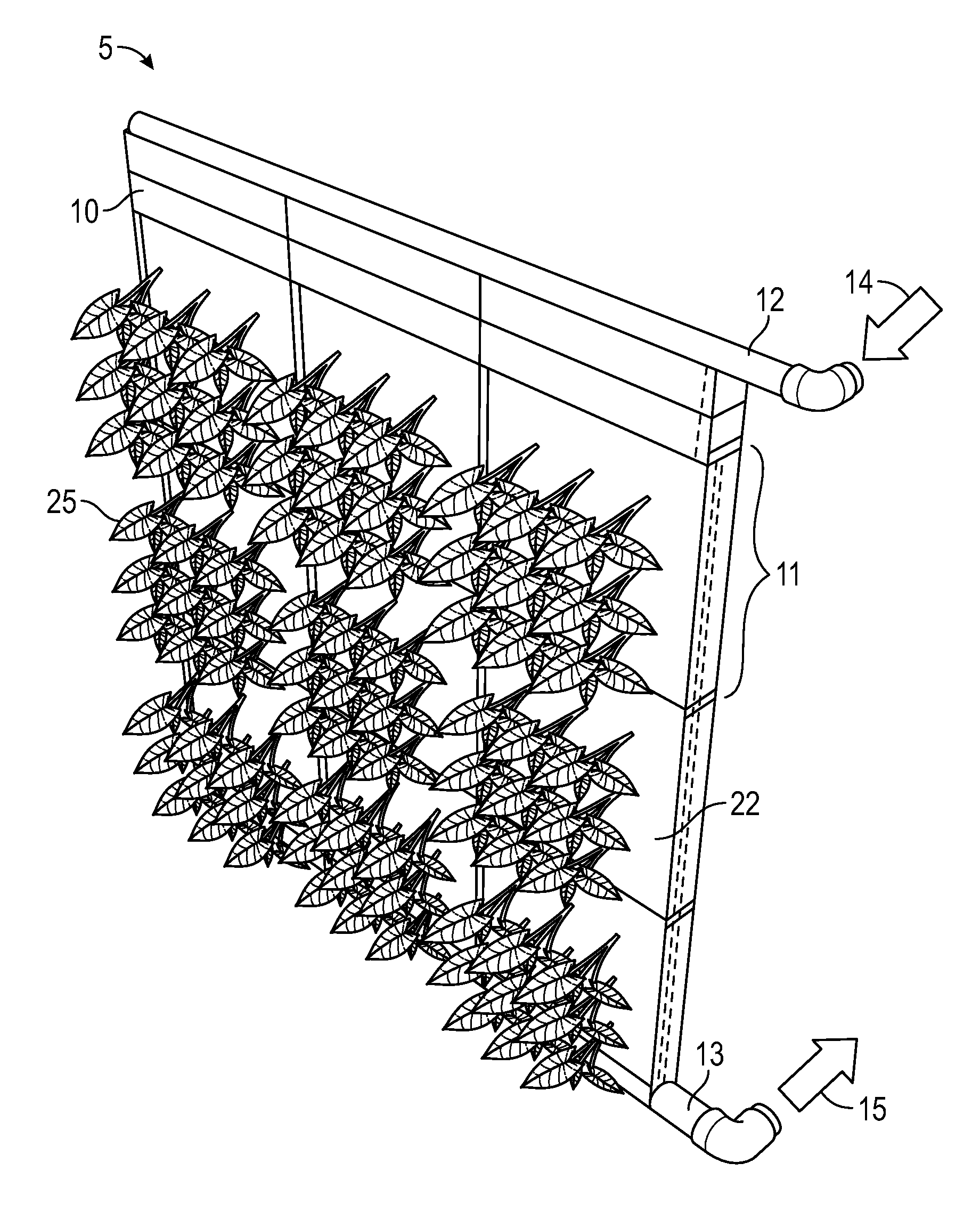

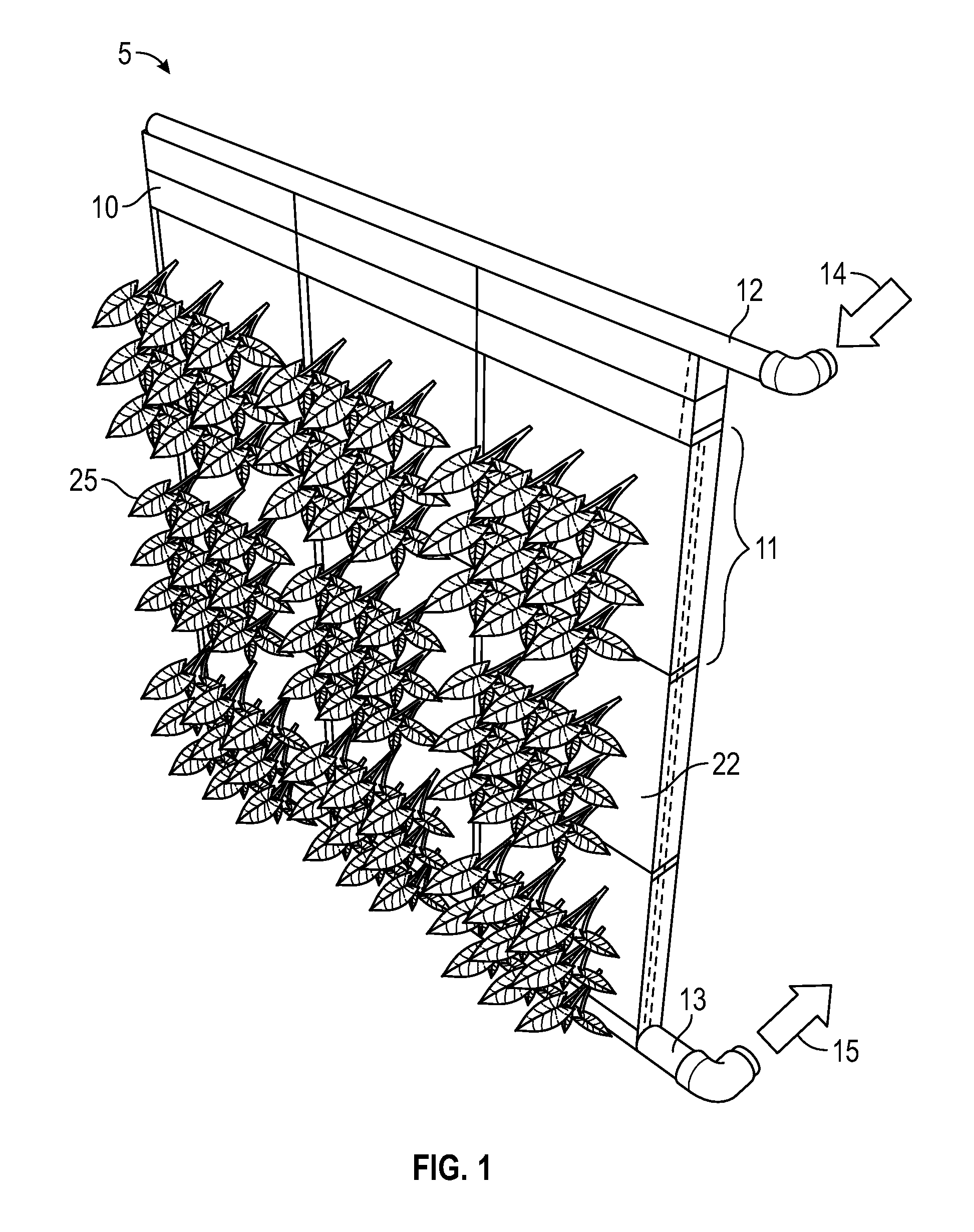

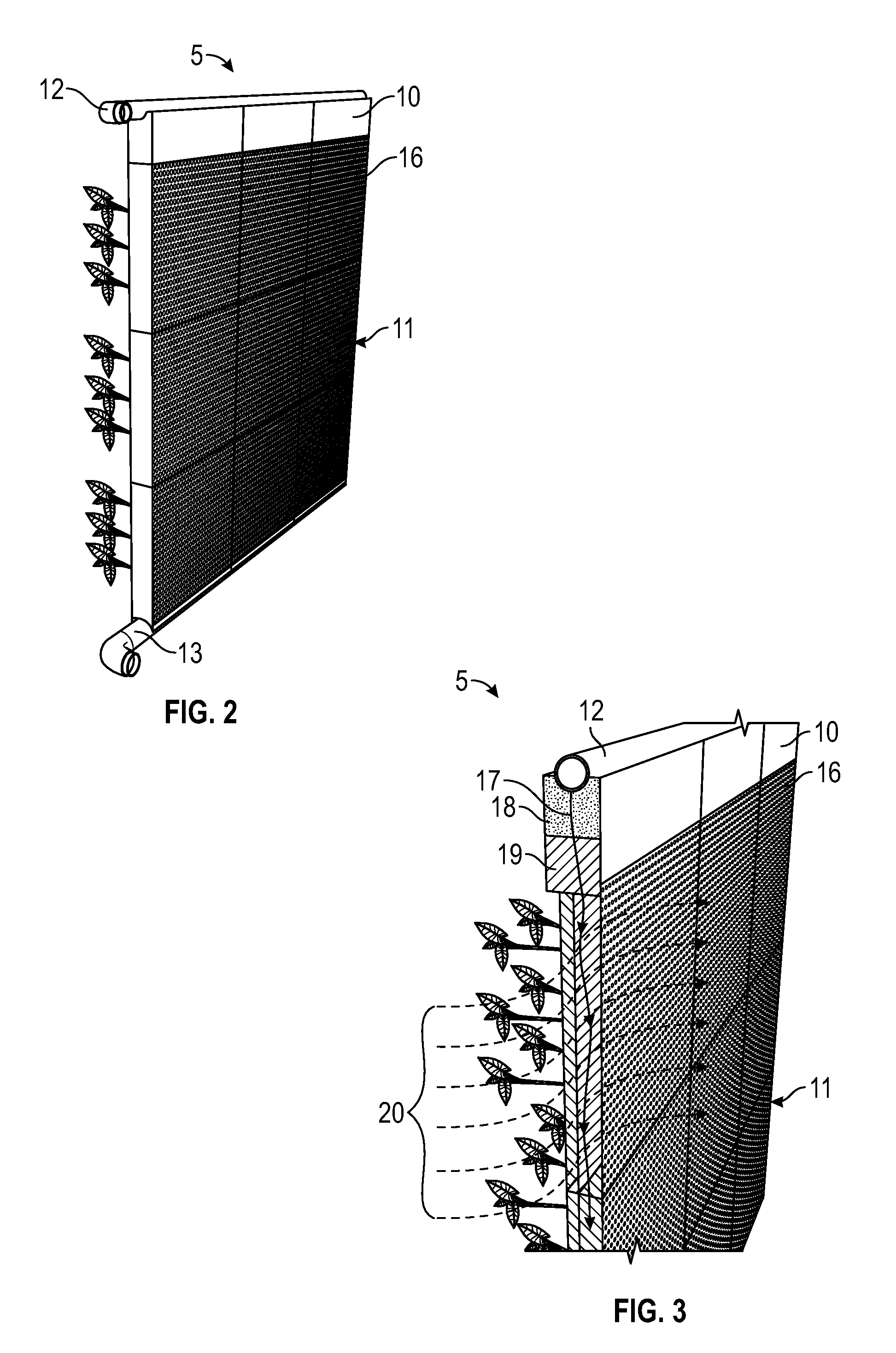

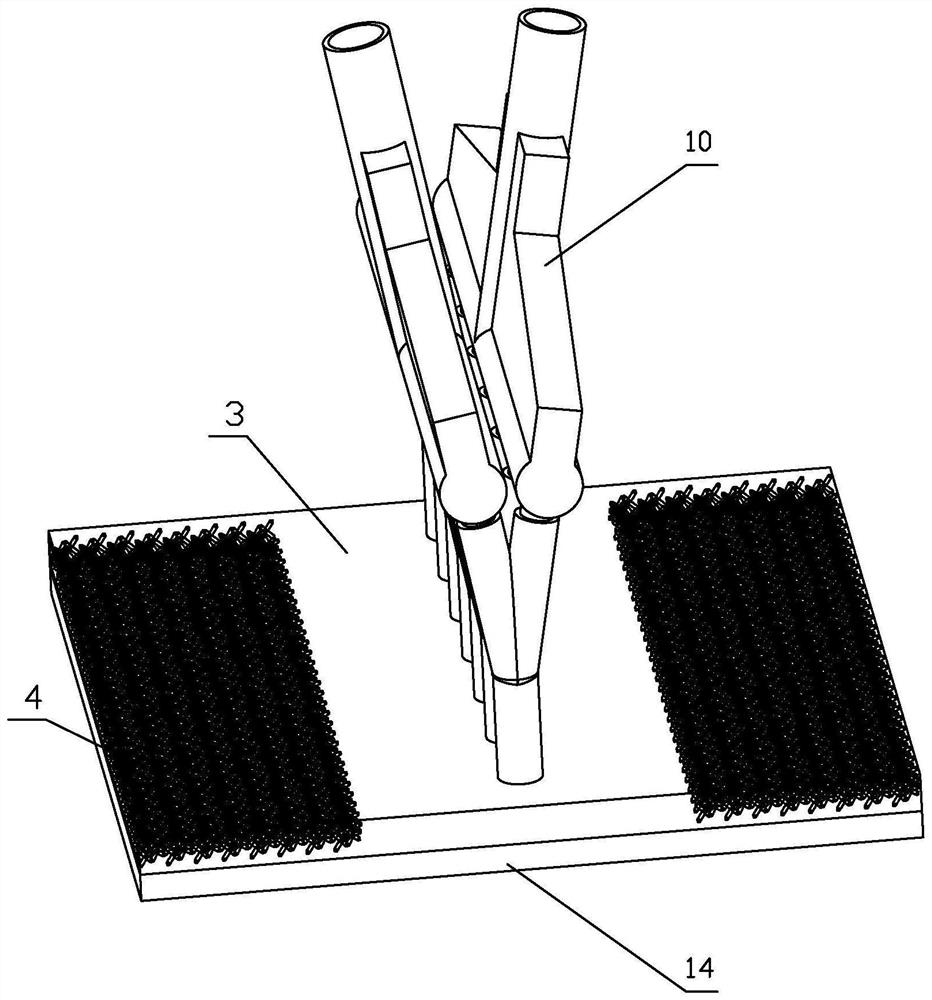

Modular Living Green Wall System to Provide Heat Rejection

InactiveUS20150289452A1Facilitates rejection/heat exchangeEasy maintenanceSelf-acting watering devicesWatering devicesPorous substrateWarm water

Modular living green wall systems are provided that supply water-cooled heat rejection for building cooling, power generation, industrial, chemical, and other processes that rely on heat rejection to the ambient environment for their efficient operation. Warm water from the process requiring heat rejection is circulated vertically through channels of porous media of the system and is cooled by evaporative and / or convective heat transfer to the ambient air that flows over and / or through the porous media across or counter to the water flow direction. Cool water leaving the system is piped to a heat exchanger of the process to provide the requisite cooling and is returned warm to the modular green wall system to complete the circulation loop. Modular living green wall systems may be assembled using plant modules and water treatment modules that are nested together to form continuous porous vertical water flow channels and a water recirculation system. The plant modules may consist of an inner porous media layer and an exposed porous substrate layer attached to each other and a stackable module housing. The water treatment module may be housed in a compatible stackable housing containing horizontal layers of filtration media. These modules are stacked in an interlocking manner and may be attached to an existing building support structure or alternatively be used to form a free standing living green wall.

Owner:YALE UNIV

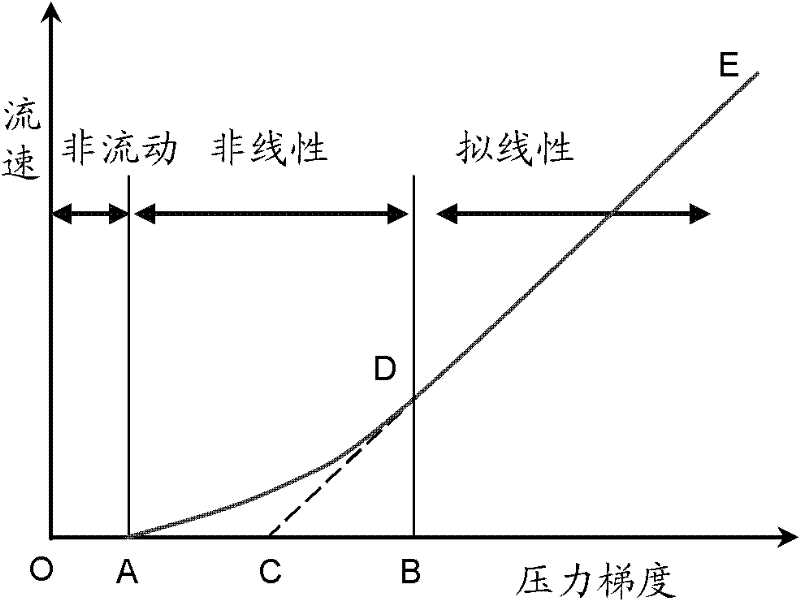

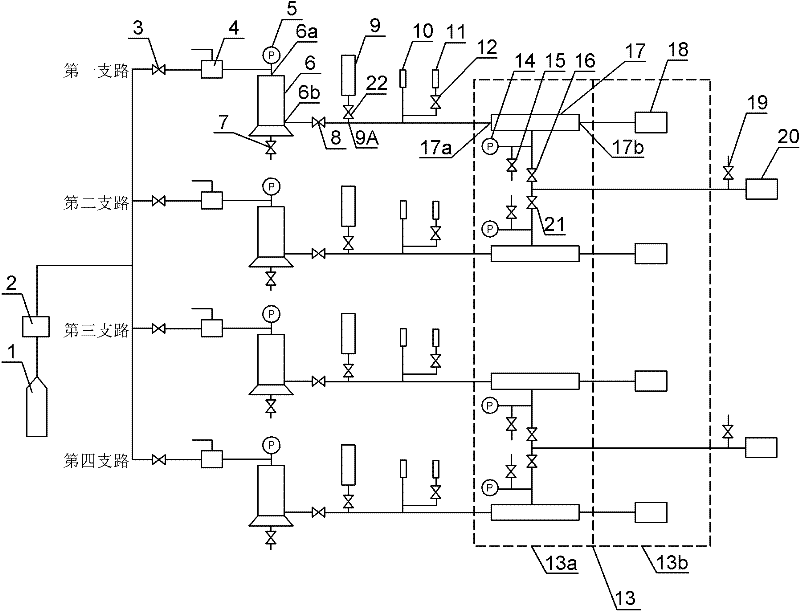

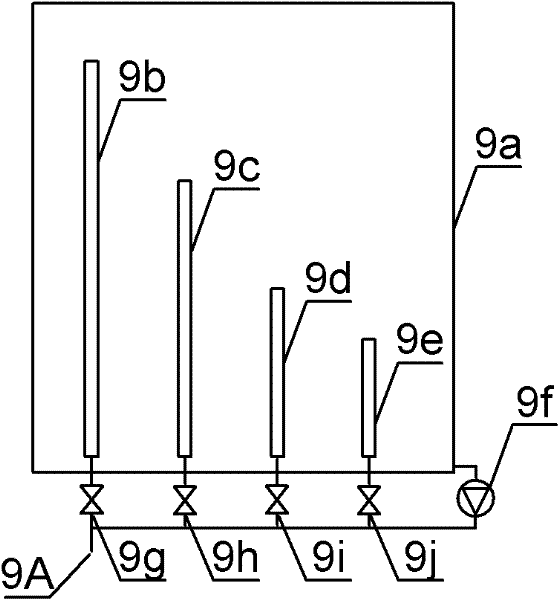

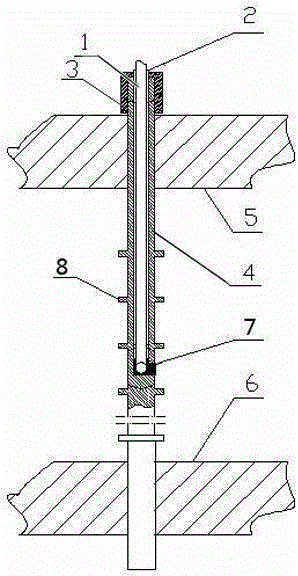

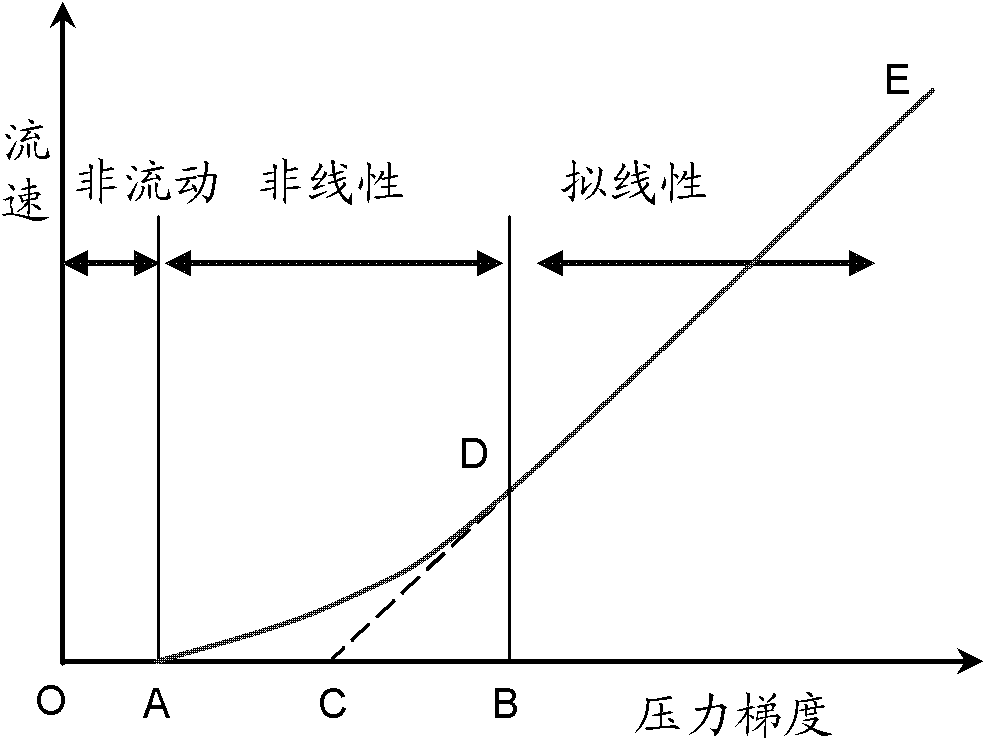

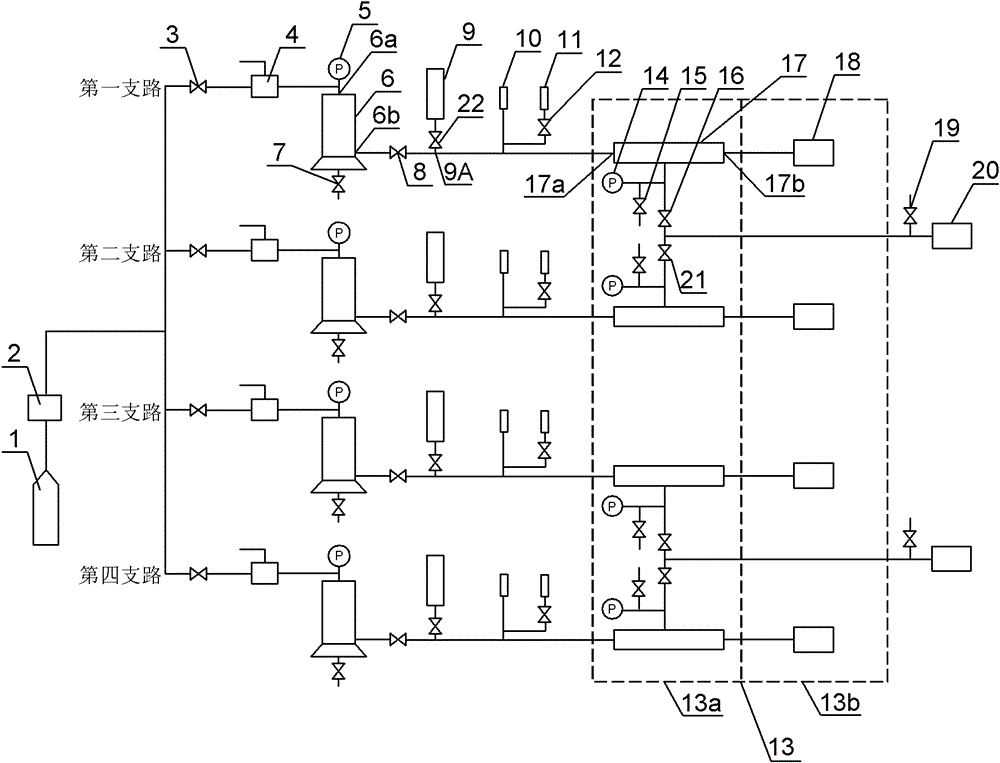

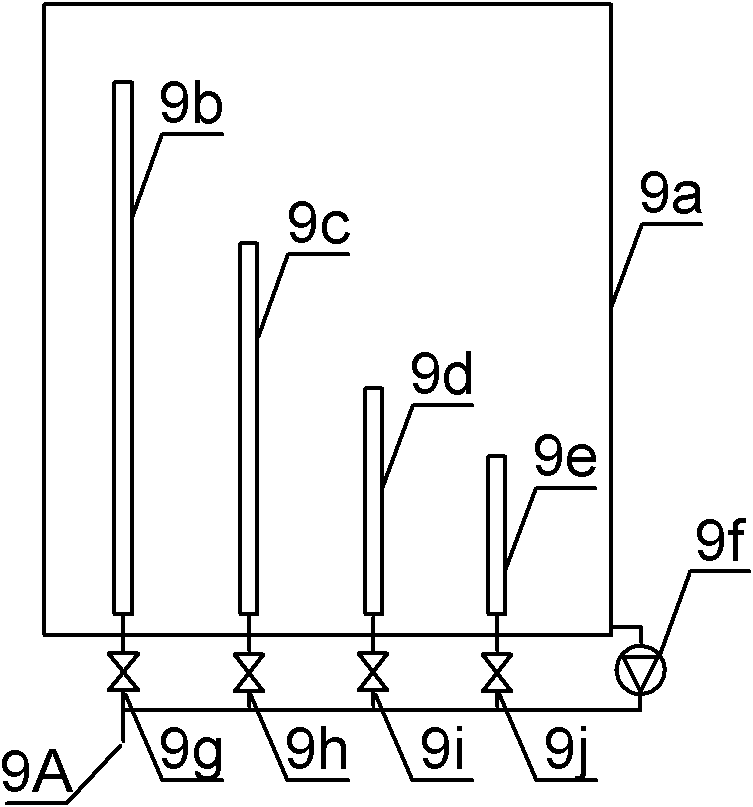

System and method for testing non-linear seepage characteristics of fluid in low-permeability porous media

ActiveCN102297830AEasy to measureLittle changePermeability/surface area analysisDischarge measurementsEngineering

The invention provides a test system and method of fluid non-linear percolation characteristics in a low-permeability porous media. The test system comprises a plurality of test branches, wherein, each test branch comprises a displacement pressure output unit for providing different pressures to transfer displacing fluid to a test core, a pressure measuring unit for the pressure of the displacingfluid output by the displacement pressure output unit, a flowing unit for accommodating the test core and providing ring crush to the test core, a flow measuring unit for measuring the flow of the displacing fluid flowing through the test core, and a thermostatically control unit for providing a constant ambient temperature for the flowing unit and the flow measuring unit. By adopting the thermostatically control unit, the influence of variation in temperature to the test results is eliminated, so that the test results are accurate.

Owner:PETROCHINA CO LTD

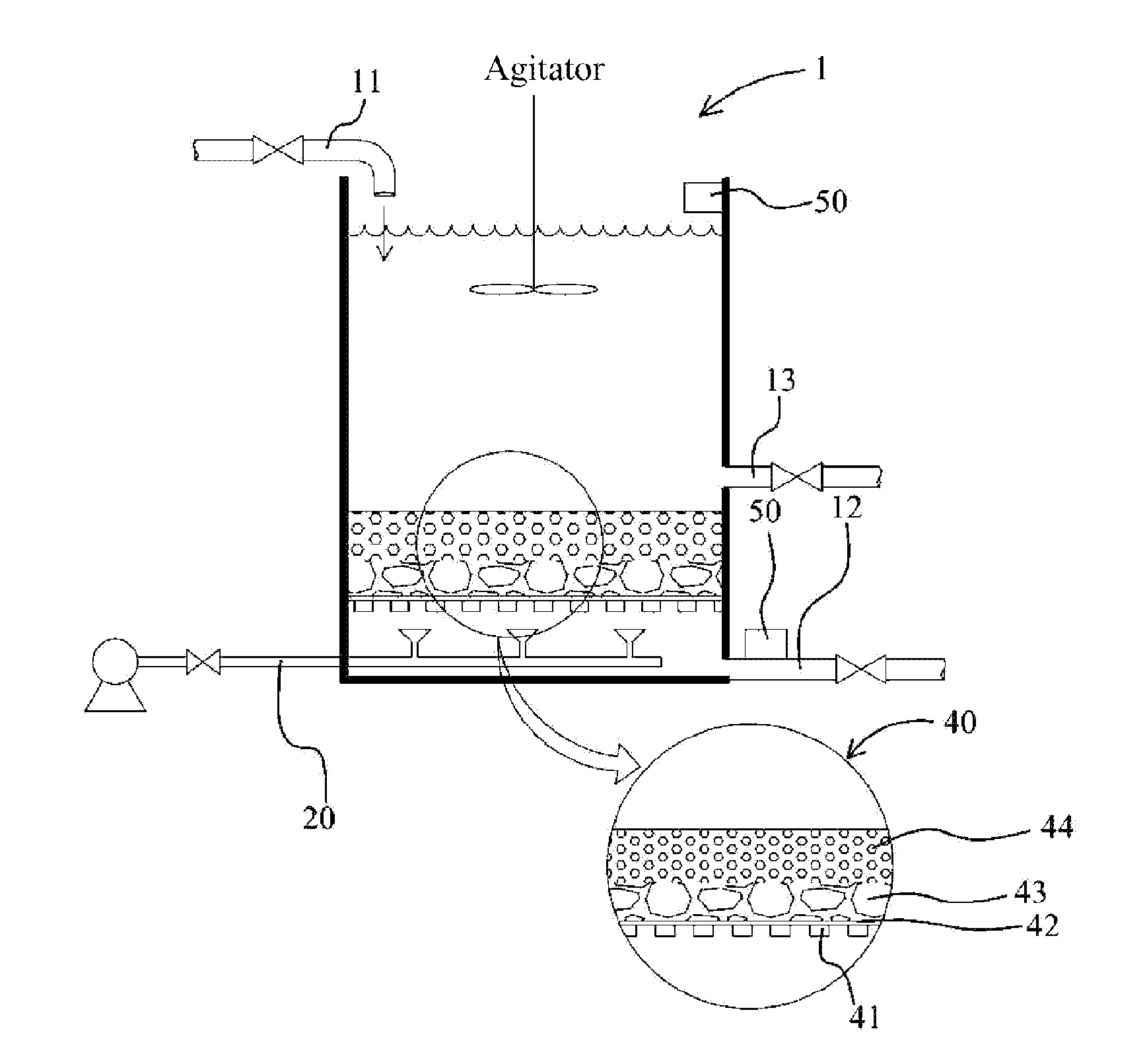

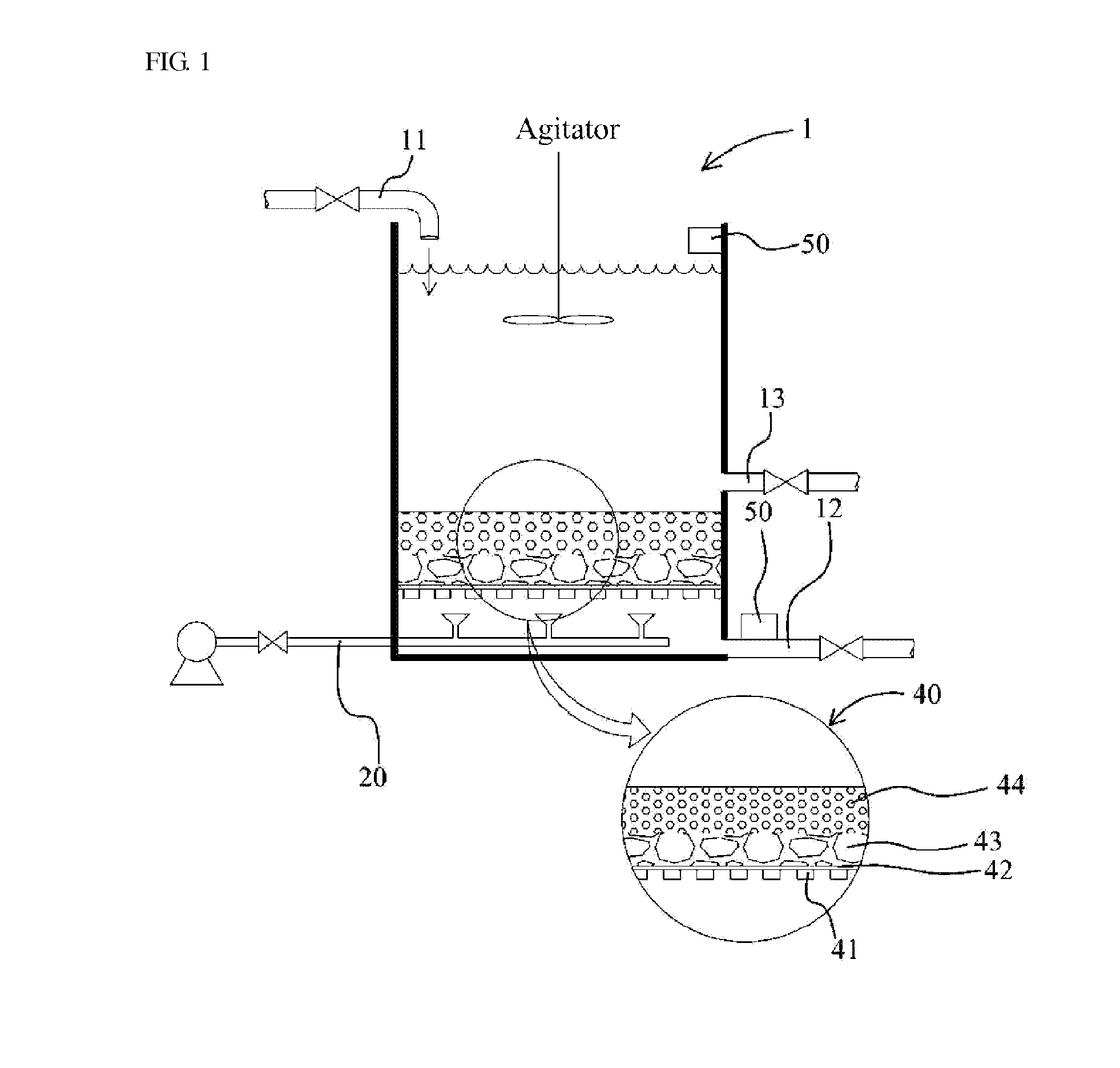

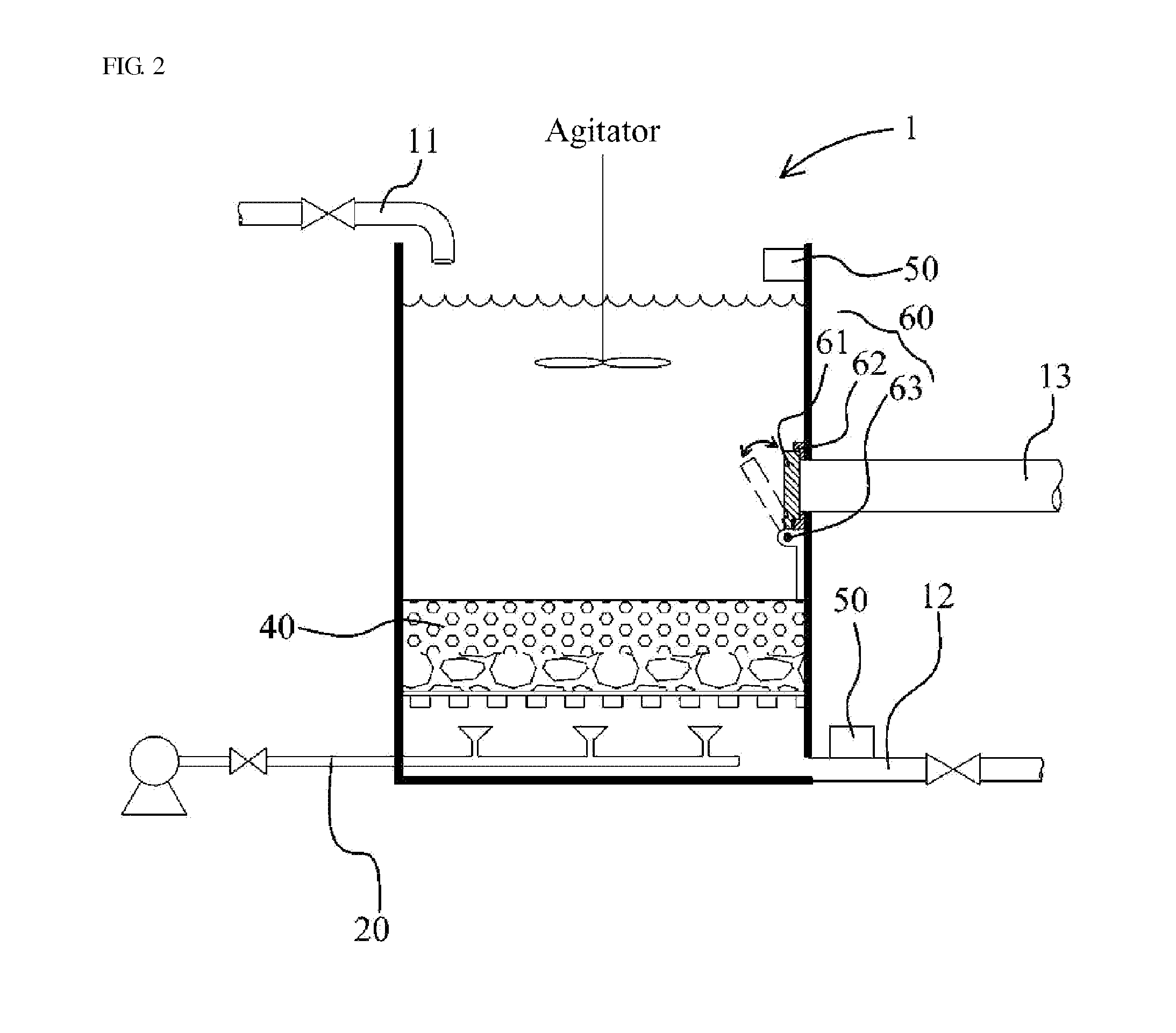

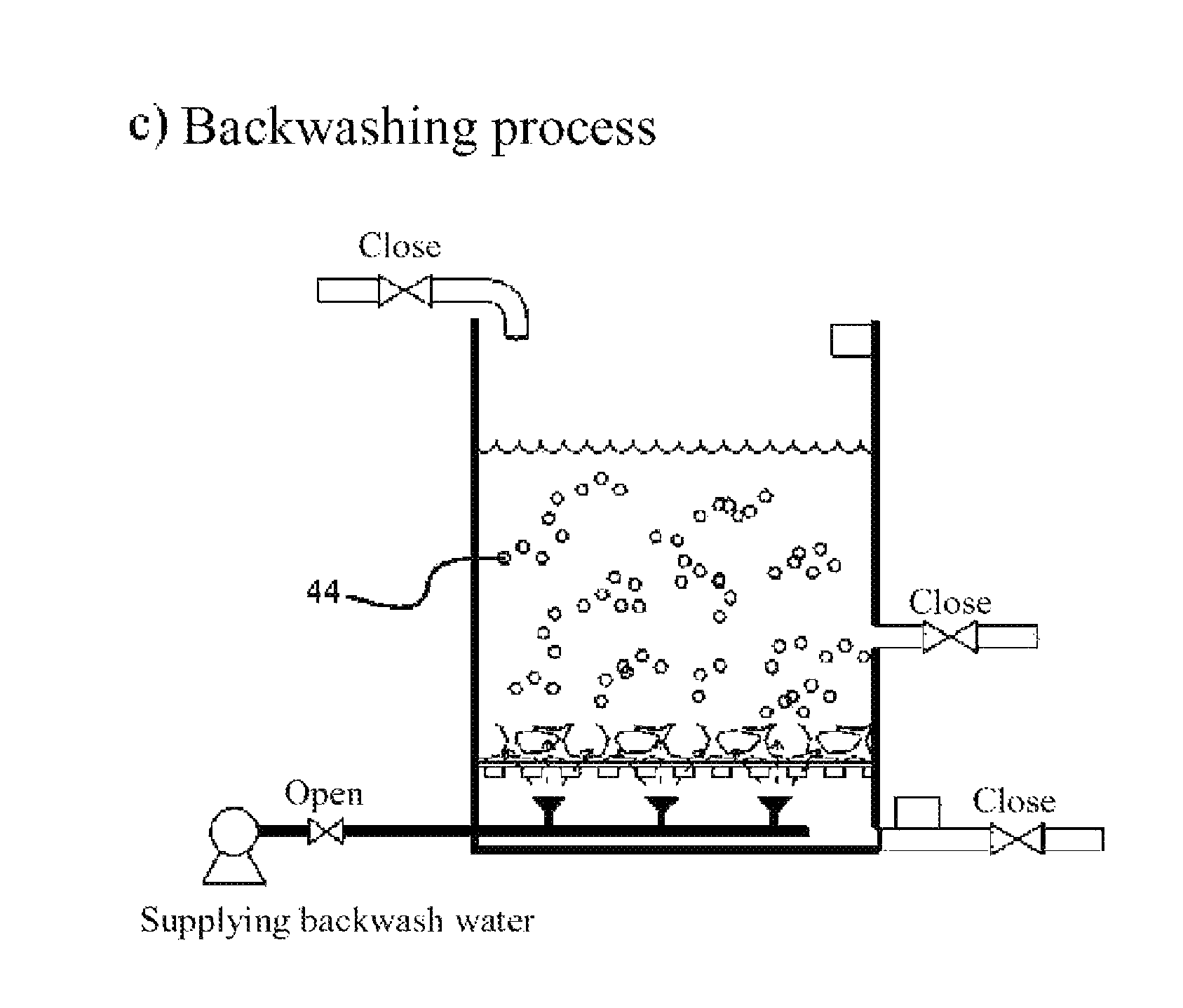

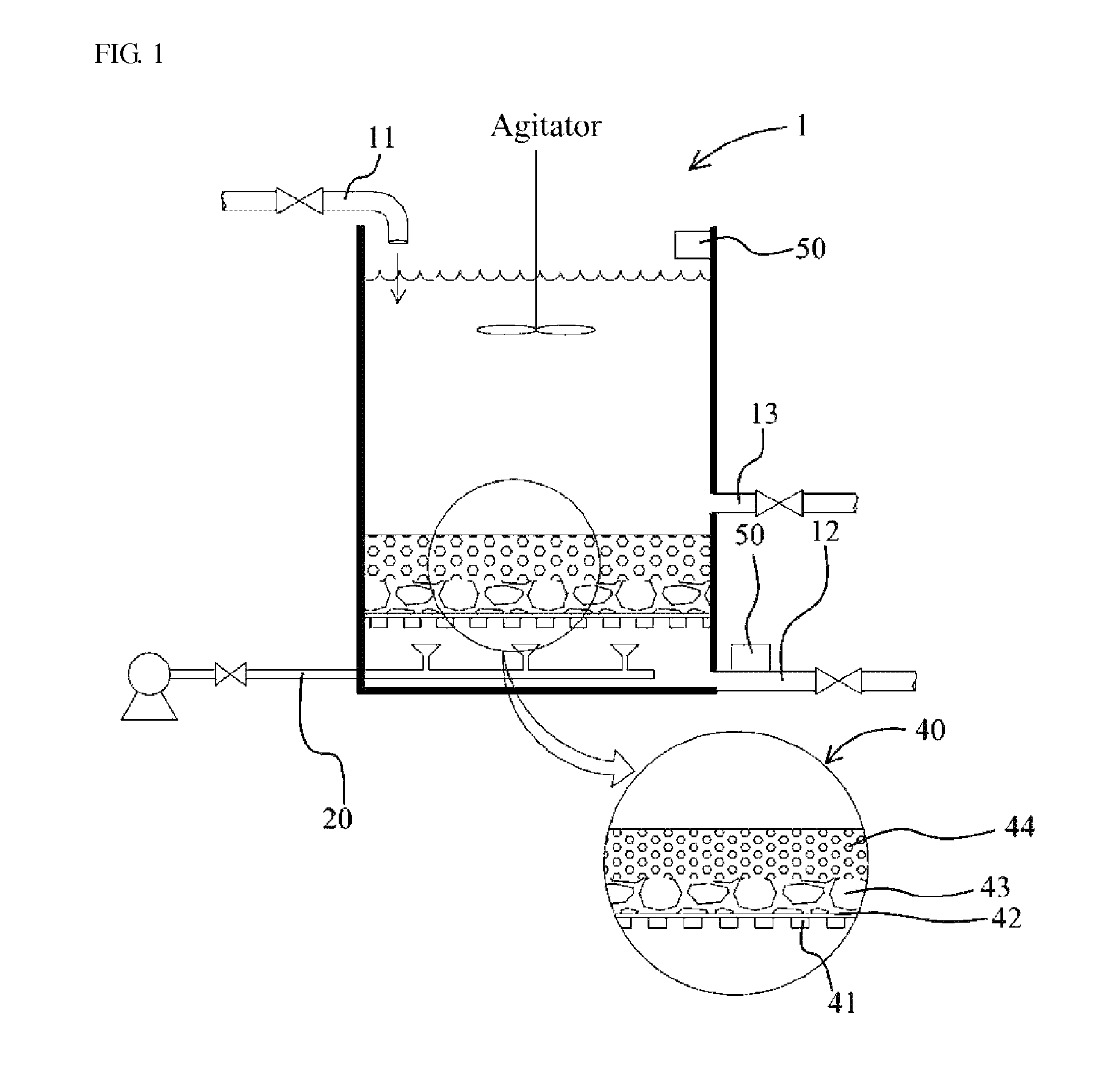

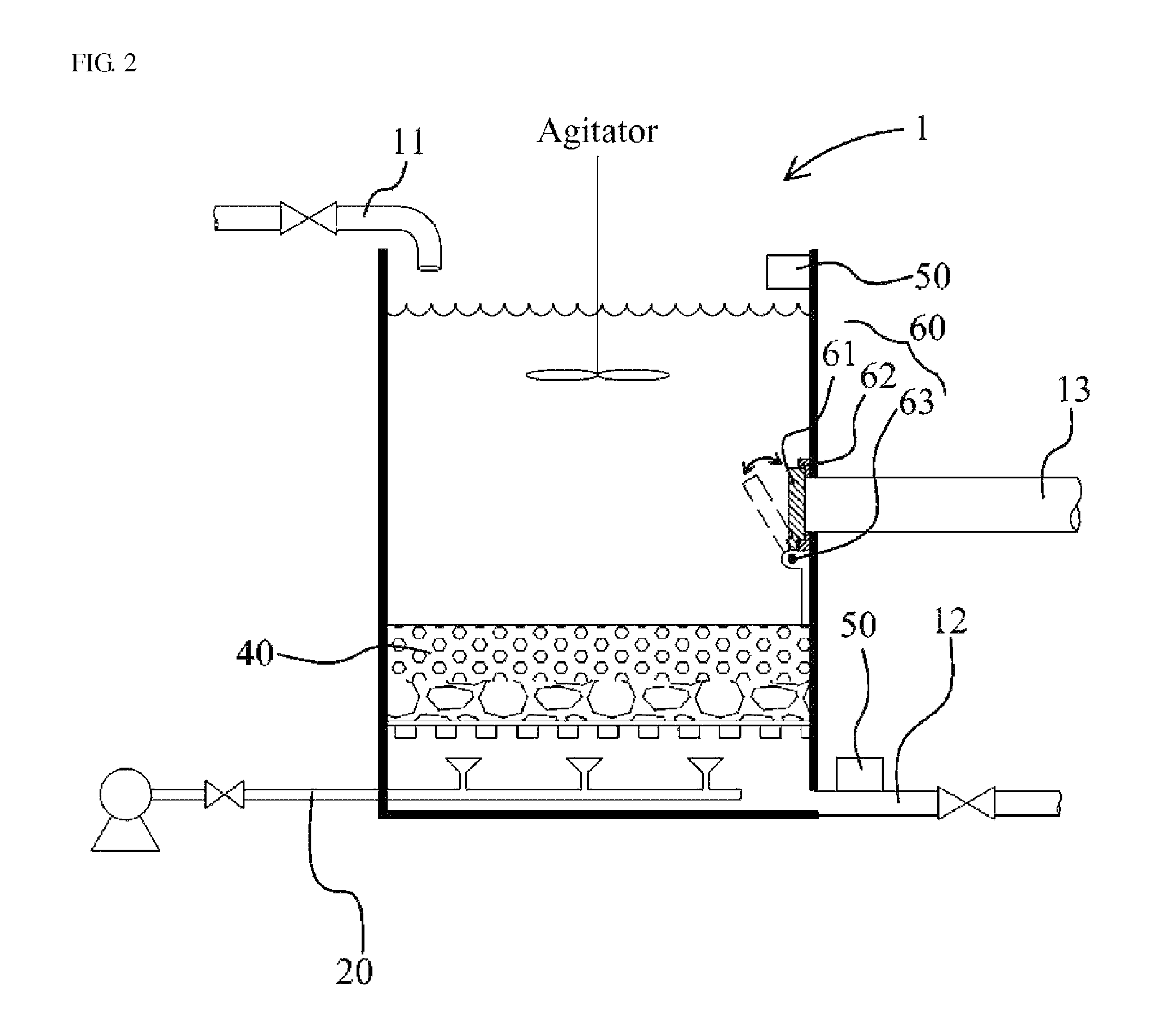

High speed filtration device using porous media, and backwash method thereof

ActiveUS20120211430A1Improve filtration efficiencyReducing unnecessary excessive consumptionGeneral water supply conservationSpecific water treatment objectivesFiltrationWater flow

The present invention relates to a porous media-mediated high speed filtration device for easy backwash, wherein the inflow water to be filtered is guided to an upper portion of the high speed filtration device and is filtered by downflow and porous media are backwashed for maintaining optimum filter efficiency by blocking the flow of inflow water and water to be treated after sensing the level of the inflow water or the change in the flux of the water to be treated, supplying backwash water and / or air by upflow through a backwash equipment to separate pollutants in the porous media by the collision and friction between the porous media by flowing of the porous media through the stream of the backwash water, placing the porous media in a stationary location, and discharging the pollutants through a discharge pipe of the high speed filtration device before the pollutants settle. In addition, the present invention comprises a backwash method of the high speed filtration device using porous media.

Owner:SUNG PIL CHOI

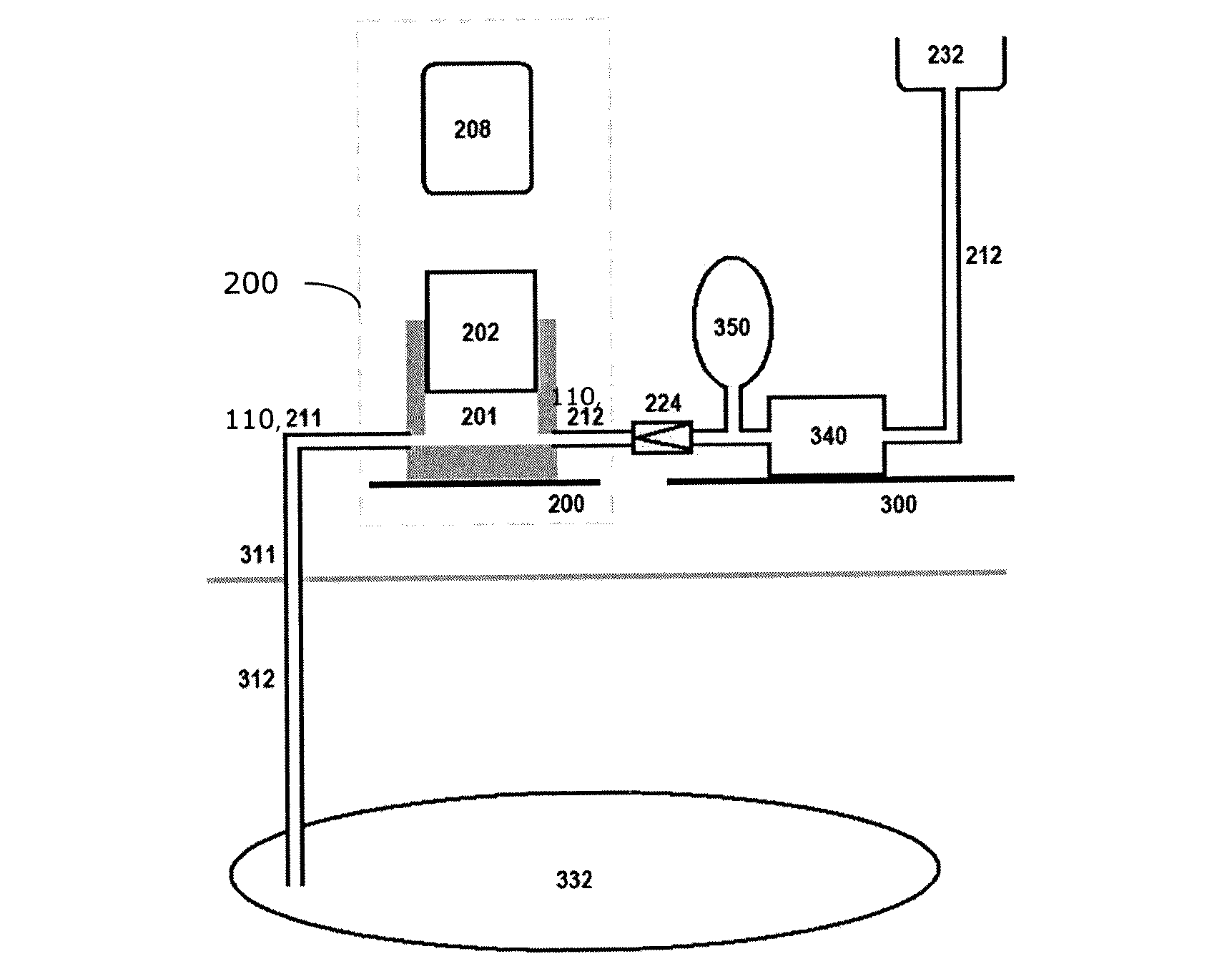

Method for recovery of hydrocarbon fluid

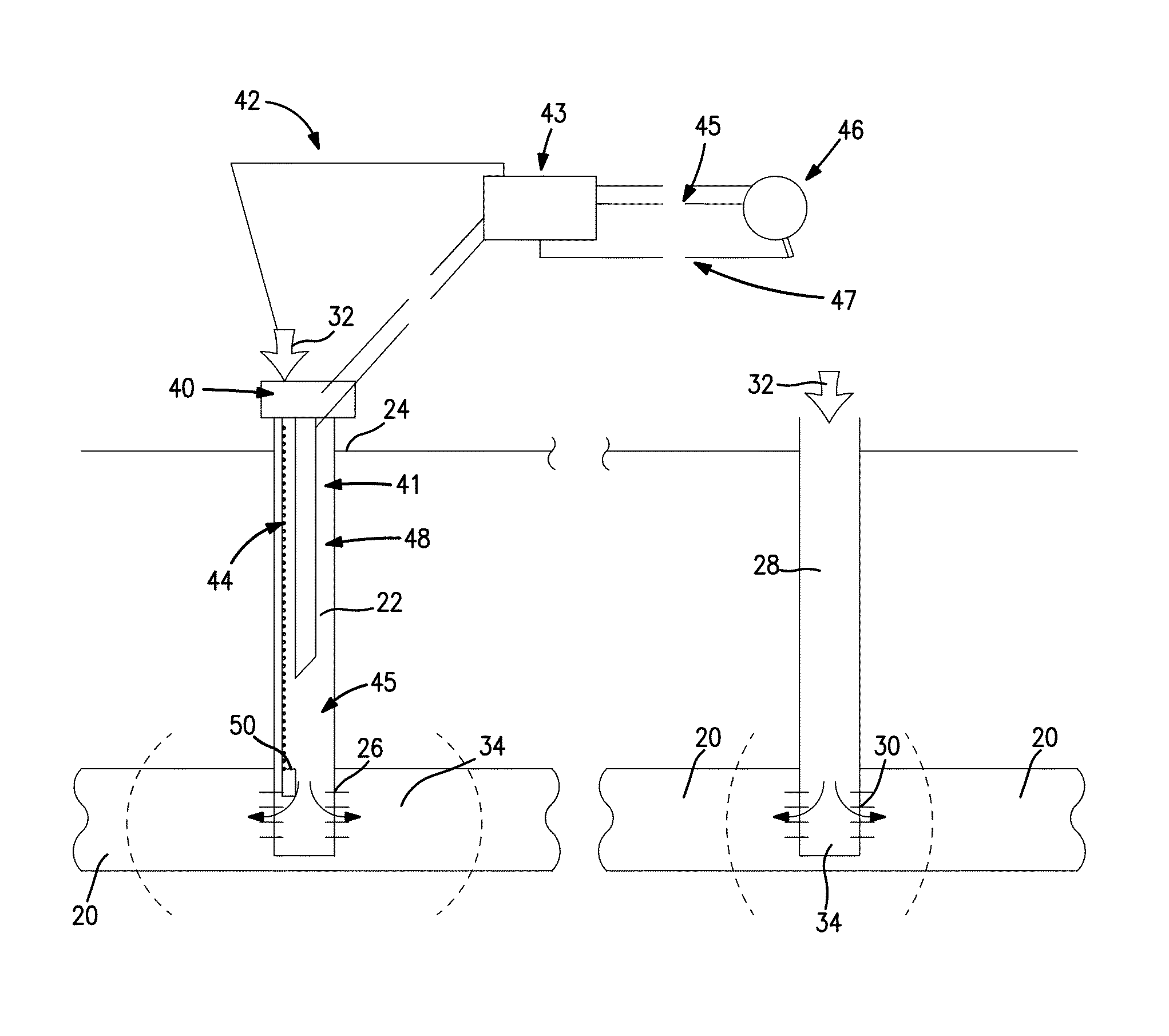

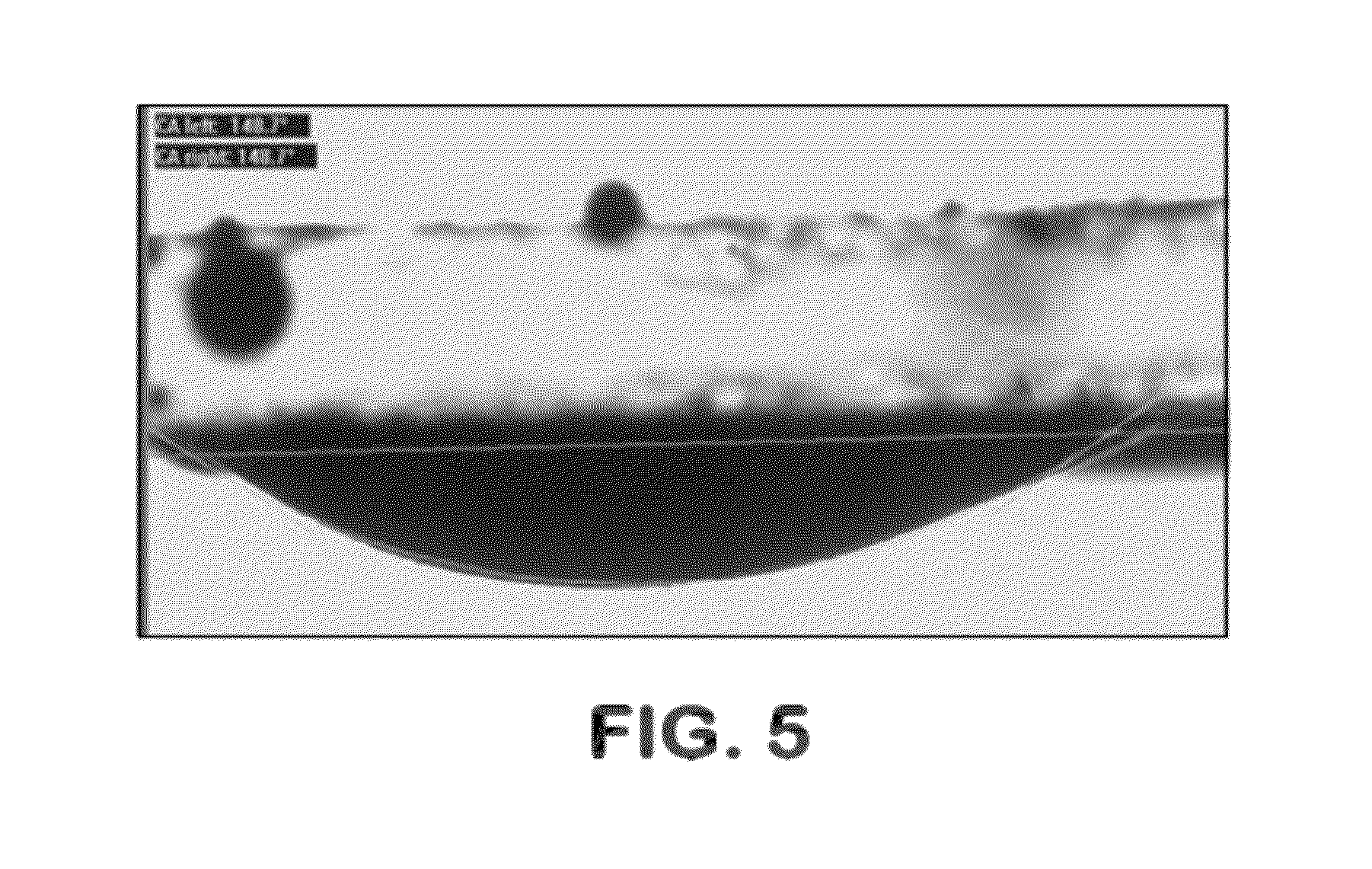

InactiveUS20140338895A1Increase hydrocarbon recovery factorPromote recoverySurveyFluid removalPressure risePressure amplitude

A method is described for recovery of a hydrocarbon fluid from a porous medium by injection of a fluid into the porous medium. The method includes determining a Rayleigh time on the basis of the density of the fluid and the hydrocarbon fluid, the median pore diameter of the porous medium, and surface tension between the fluid and the hydrocarbon fluid. Further, pressure stimulation is provided in the fluid and generated by a collision process with a collision contact rise time which is of the range of 1-100 times the Rayleigh time. Alternatively or additionally, the providing a pressure stimulation in the fluid include generating an impact pressure with a pressure amplitude I and a pressure rise time Δt, where the pressure amplitude is larger than the relation γcΔt / a2, where γ is the surface tension between the fluid and the hydrocarbon fluid, and c is the speed of sound in the porous media. In aspects of the invention, the method includes arranging a chamber in fluid communication with the porous medium via at least one conduit, and having the chamber comprising first and second wall parts movable relative to each other. The pressure stimulation includes providing an impact pressure in the fluid to propagate to the porous medium via the conduit, and where the impact pressure is generated by the collision process between an object arranged outside of the fluid and the first wall parts for the first wall part to impact on the fluid in the chamber.

Owner:IMPACT TECH SYST

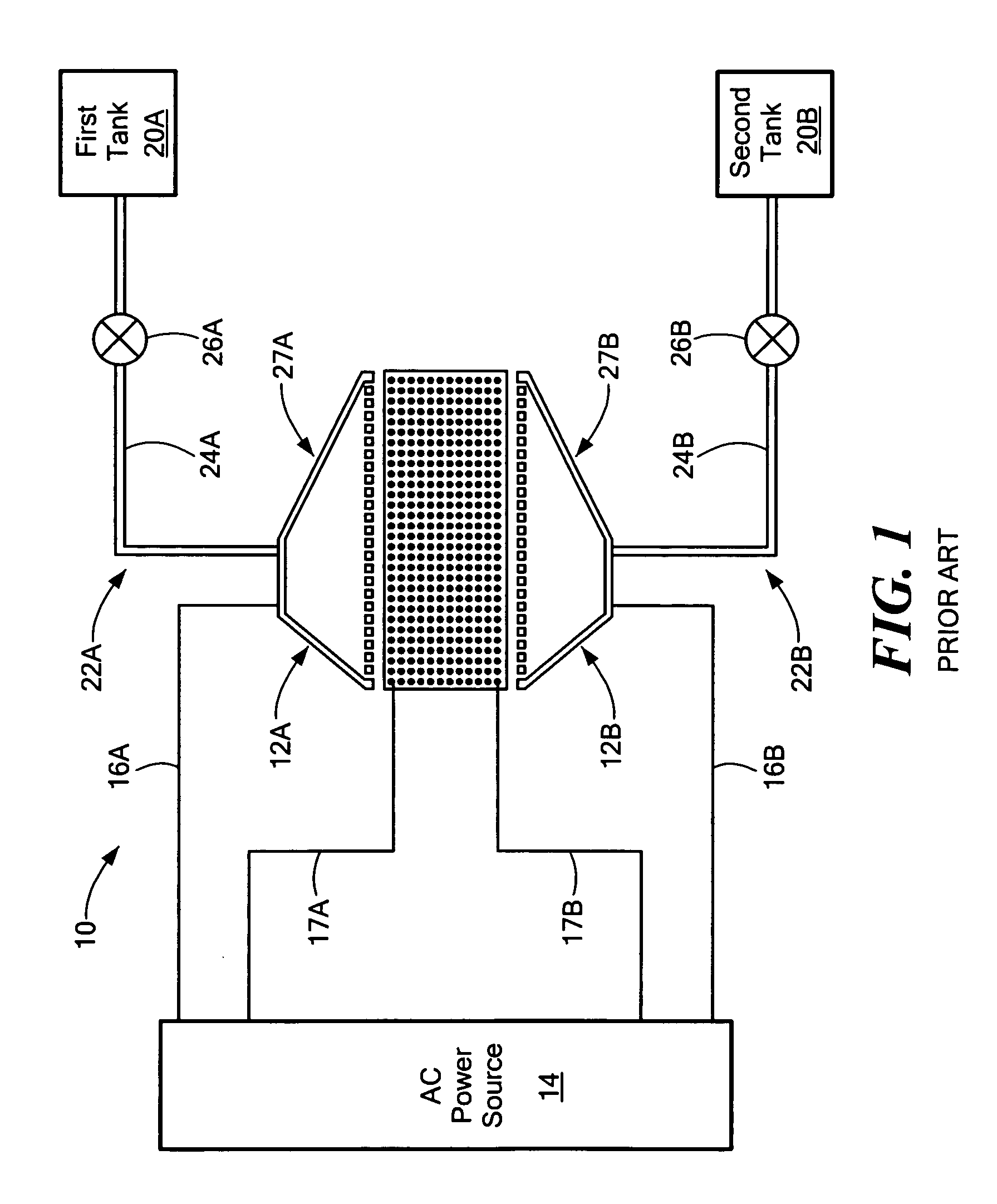

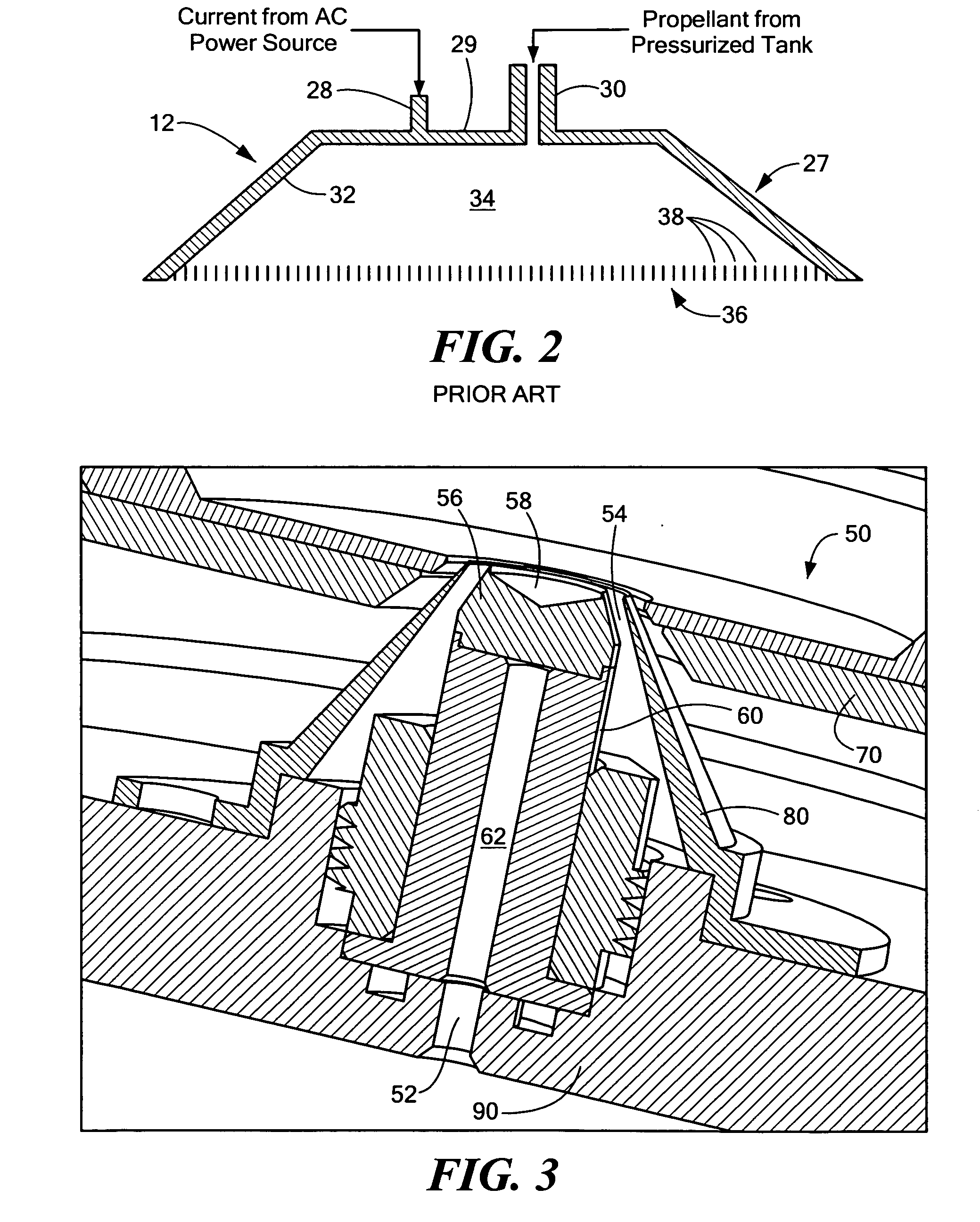

Electrospray source

ActiveUS20090113872A1Easy to manufactureReduce manufacturing costCosmonautic vehiclesCosmonautic propulsion system apparatusWorking fluidEngineering

An electrospray source useful for a variety of applications and including an emitter with a porous media flow distributor having a surface forming multiple Taylor cones. A casing about the porous media flow distributor controls the direction of a working fluid through the porous media. An extractor is at a potential different than the emitter for forming the Taylor cones. A guard electrode is disposed between the emitter and the extractor and is at or above the potential of the emitter for shaping the electric field formed between the emitter and the extractor.

Owner:BUSEK

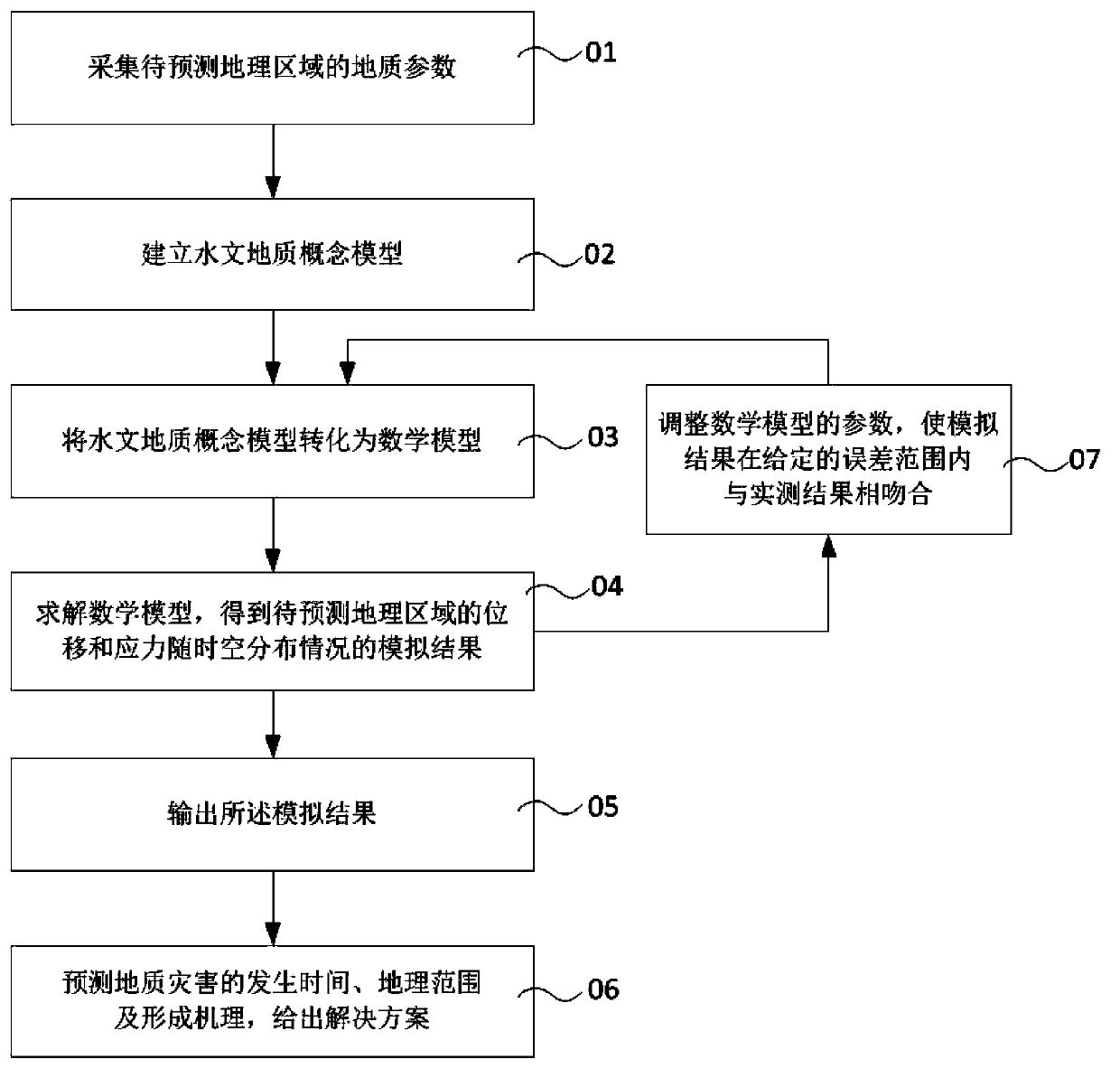

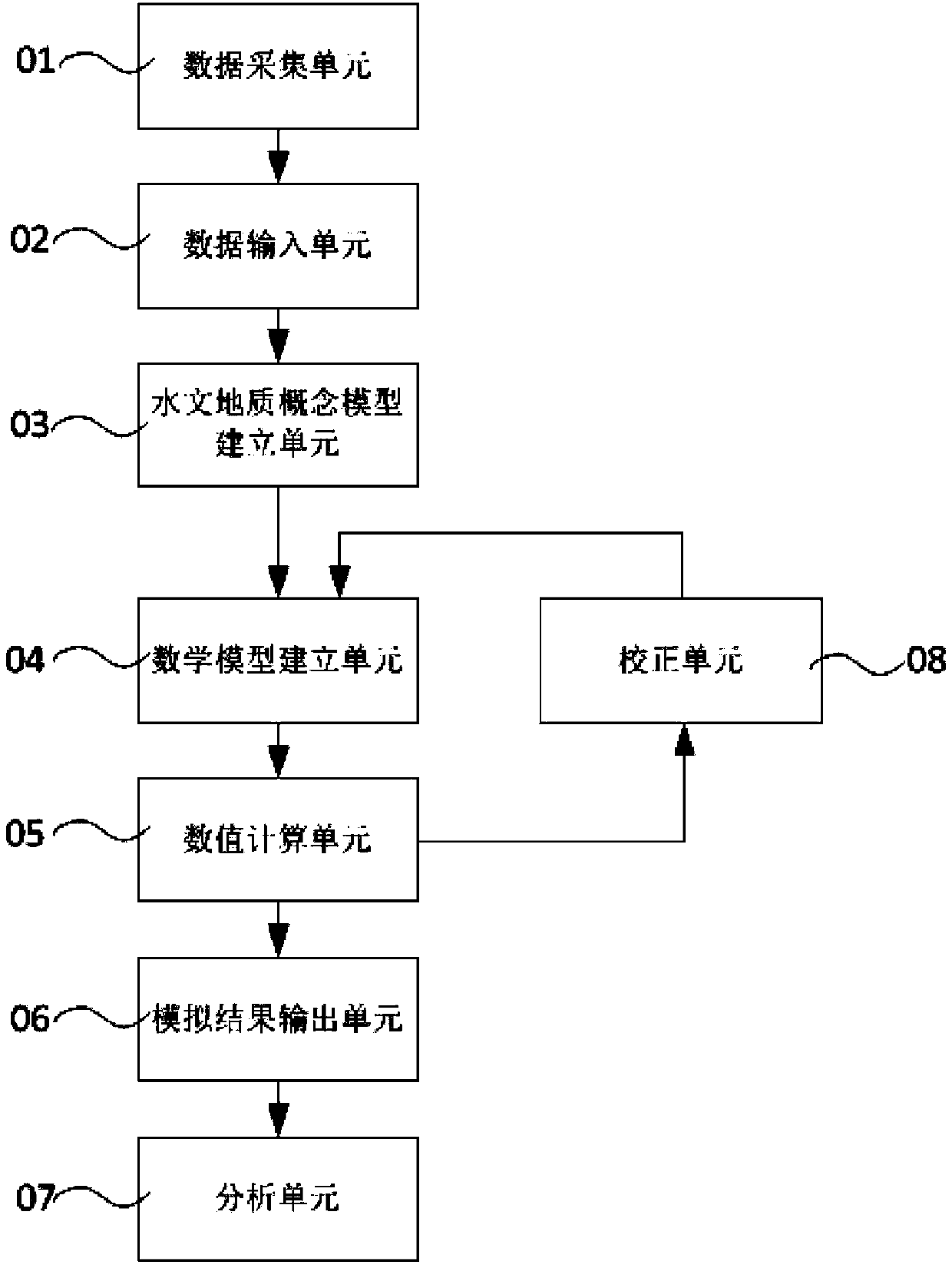

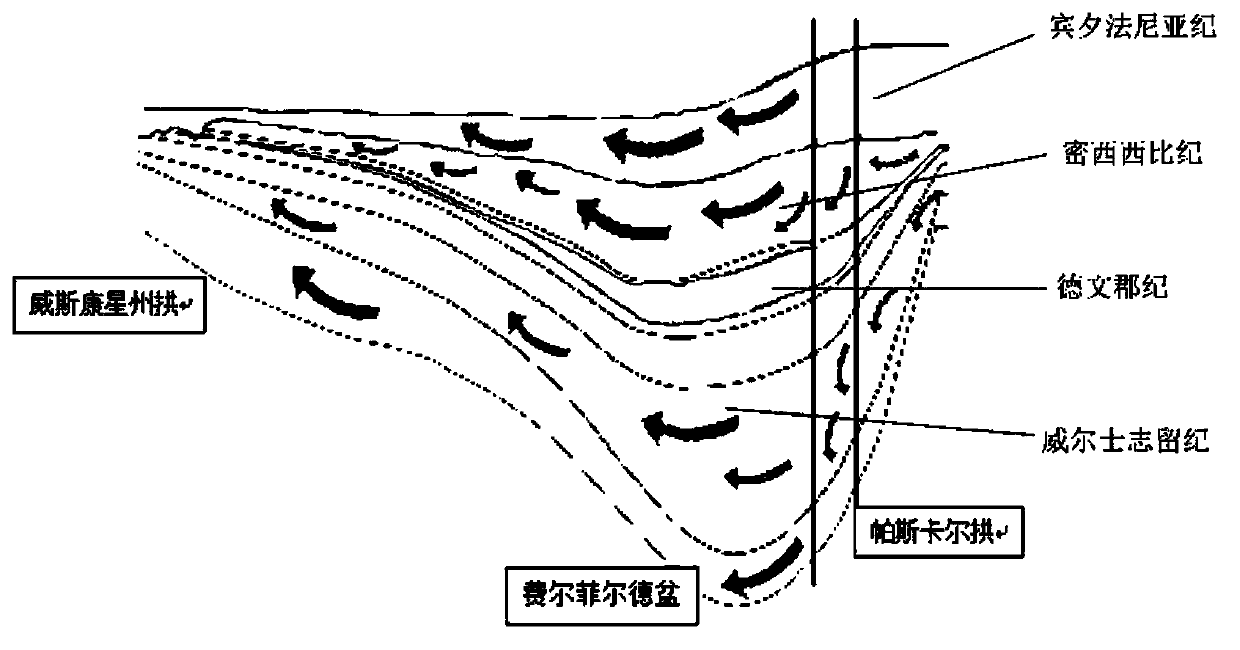

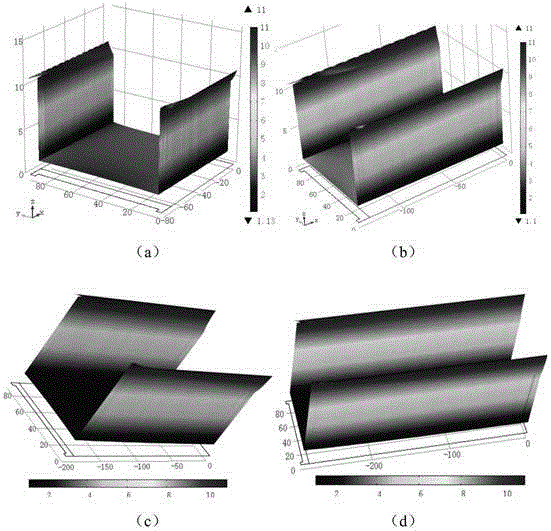

Geological disaster prediction system and method based on porous media fluid-structure interaction model

InactiveCN103425877AAccurate predictionDivide at willSpecial data processing applications3D modellingGeographic featureFluid–structure interaction

The invention relates to a geological disaster prediction system and method based on a porous media fluid-structure interaction model. The geological disaster prediction system and method based on the porous media fluid-structure interaction model comprises the following steps that geological parameters of a geological area to be predicted are collected; according to the geological characteristics and geological parameters of the geological area to be predicted, a hydrogeology concept model is built; according to the geological disaster type to be predicted and the geological characteristics of the area to be predicted, a finite element method is adopted to convert the hydrogeology concept model into a corresponding three-dimensional underground water mathematic model, and the displacement of the geological area to be predicted and the simulation result of distribution situation of stress along with space and time are obtained; the simulation result is output in the mode of image and / or data characters, and the simulation result is used for describing flowing of water among gap media and the sedimentation situation of underground soil; the occurrence time, the geological range and the forming mechanism of the geological disaster are predicted, and a solution scheme is given. The geological disaster predication system and method based on the porous media fluid-structure interaction model can predict geological disasters such as land subsidence, foundation settlement, landslide, debris flow, operation speed is high and accuracy is good.

Owner:HUBEI THINGO TECH DEV

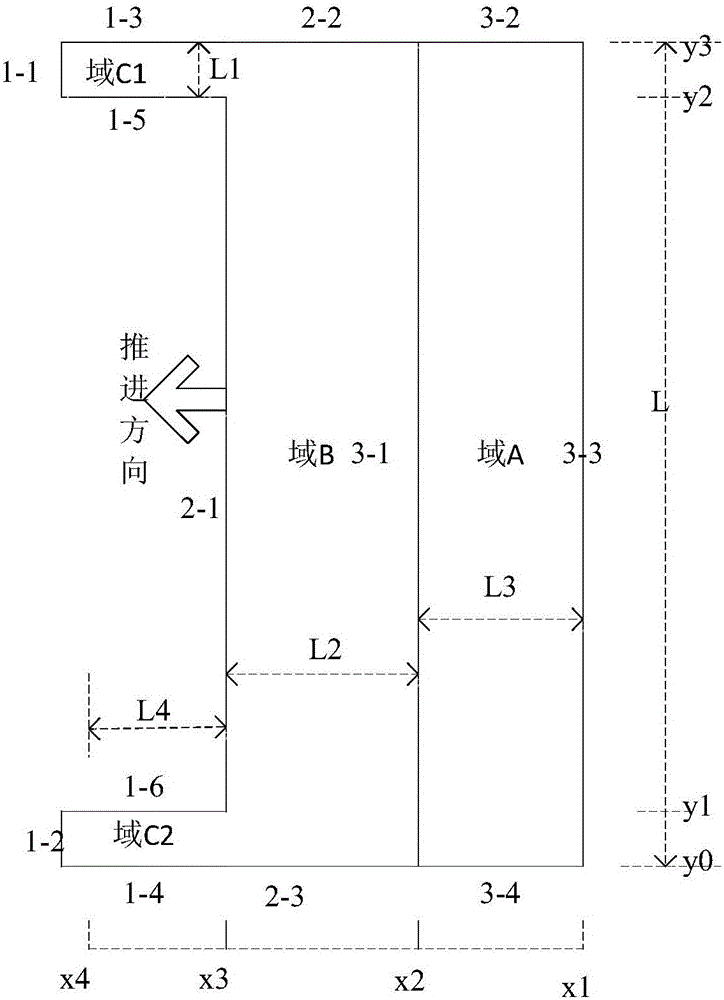

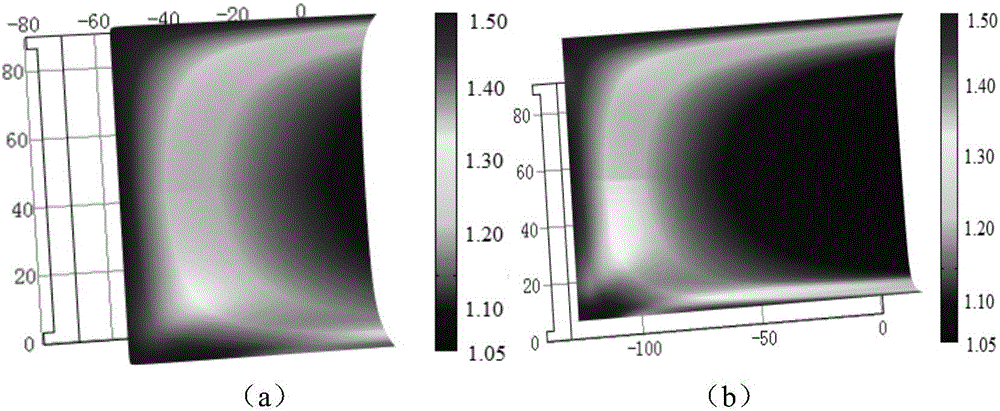

Gob air leakage flow field dynamic numerical simulation method based on deformation geometry

ActiveCN105868472AIn line with the actual project siteImprove the level of theoretical calculationSpecial data processing applicationsCAD numerical modellingStop timeGeometric modeling

The invention provides a gob air leakage flow field dynamic numerical simulation method based on deformation geometry. The method comprises the steps that an initial gob geometric model for mining on a coal face is established according to a gob formed after mining is conducted for one day at the daily average promoting speed; a free deformation area, a fixed boundary and a moving boundary of the gob are arranged; a gob air leakage flow field is arranged; the initial gob geometric model is divided into boxes, and gob air leakage flow field numerical simulation calculation is carried out; the gob geometric model is promoted step by step at the daily average promoting speed and is divided into boxes again, and gob air leakage flow field numerical simulation calculation is carried out till the gob geometric model is promoted to a stop line or the gob geometric model does not arrive at the stop line but the set calculation stop time is up. According to the method, deformation geometry is adopted for controlling the dynamic evolution process of boundary movement and area changes of the coal face and the gob, and a free and porous medium fluid flow control working face and the flow field of the gob are coupled to calculate and describe the dynamic change and distribution law of the gob air leakage flow field.

Owner:LIAONING TECHNICAL UNIVERSITY

A numerical simulation method for sand control screen pipe erosion in deep water gas well

PendingCN109543290AAccurate control of erosion and wearShorten the timeGeometric CADDesign optimisation/simulationGas solidThroat

A numerical simulation method for sand control screen pipe erosion in deep water gas well includes dividing the erosion and wear process into gas-solid two-phase coupling flow and erosion and wear ofsand particle on wall surface according to the erosion and wear mechanism of sand particle on screen pipe. For the gas-solid two-phase coupled flow problem, firstly, the physical model of screen-pipebasin is constructed, because the gravel layer and screen-pipe filter unit are solid porous media, it is simplified to a porous media basin with certain pore throat size, permeability and porosity inthe physical model. Then, the gas-solid coupling motion model is introduced to describe the turbulent flow pattern of two-phase flow, and the two-phase flow field distribution is obtained. For the problem of sand erosion and wear on the screen filter unit, the physical model of screen hole and crevice basin is established, and the wide angle screen pipe erosion model of discrete particles is established. The boundary conditions of gas-solid two phases at the entrance of the screen hole and crevice basin are determined by combining the flow field distribution. The numerical simulation of sand erosion and wear rate is carried out.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

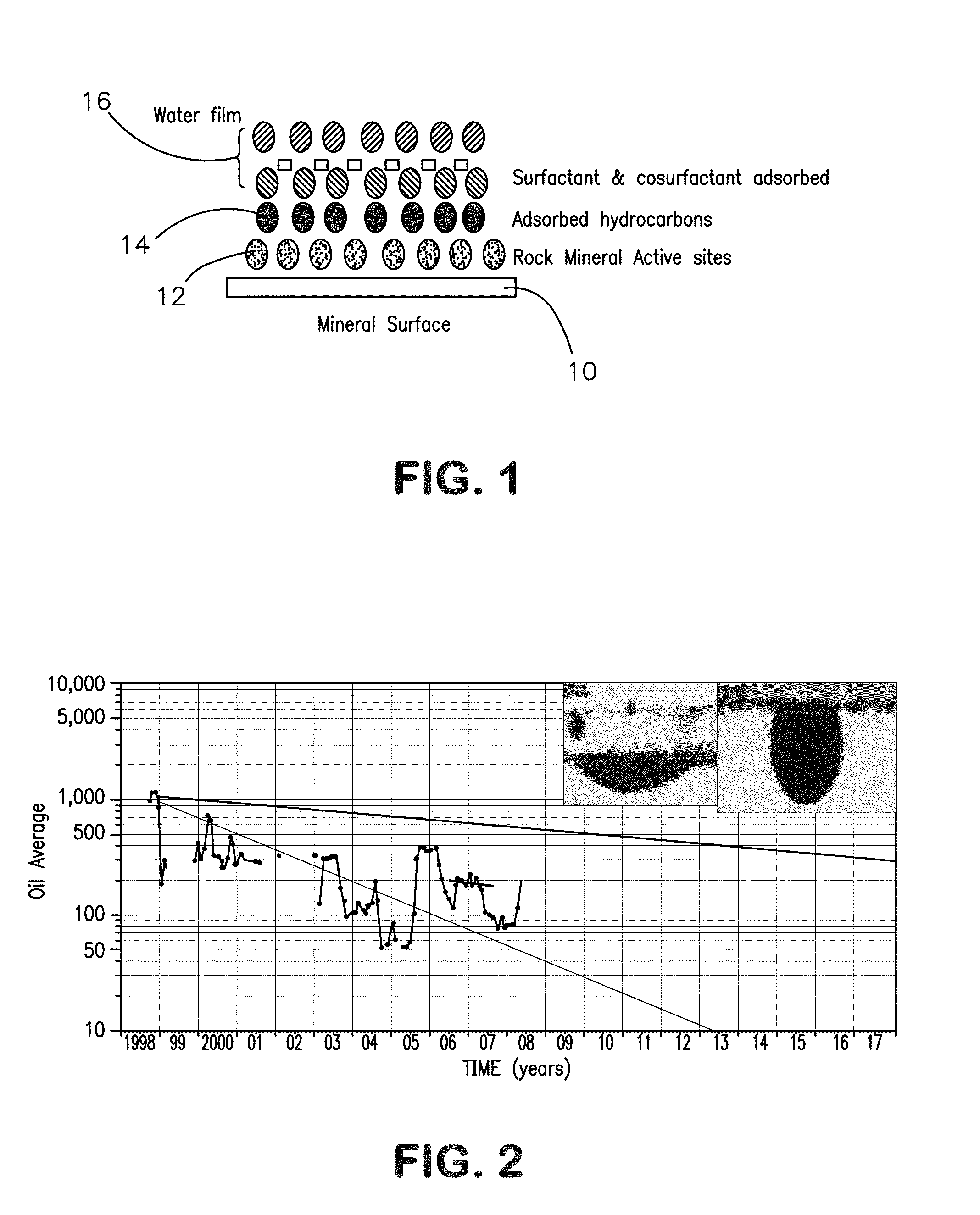

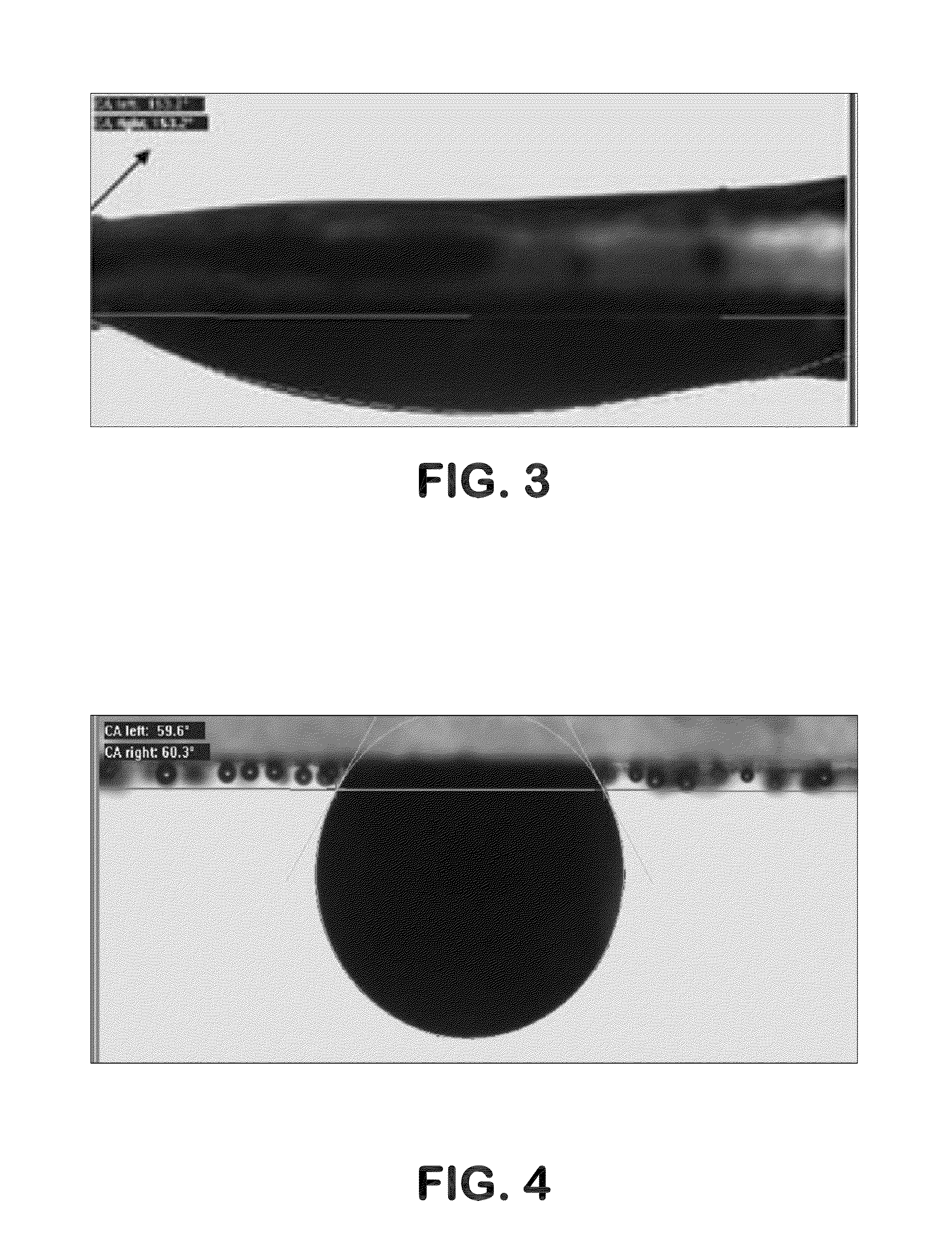

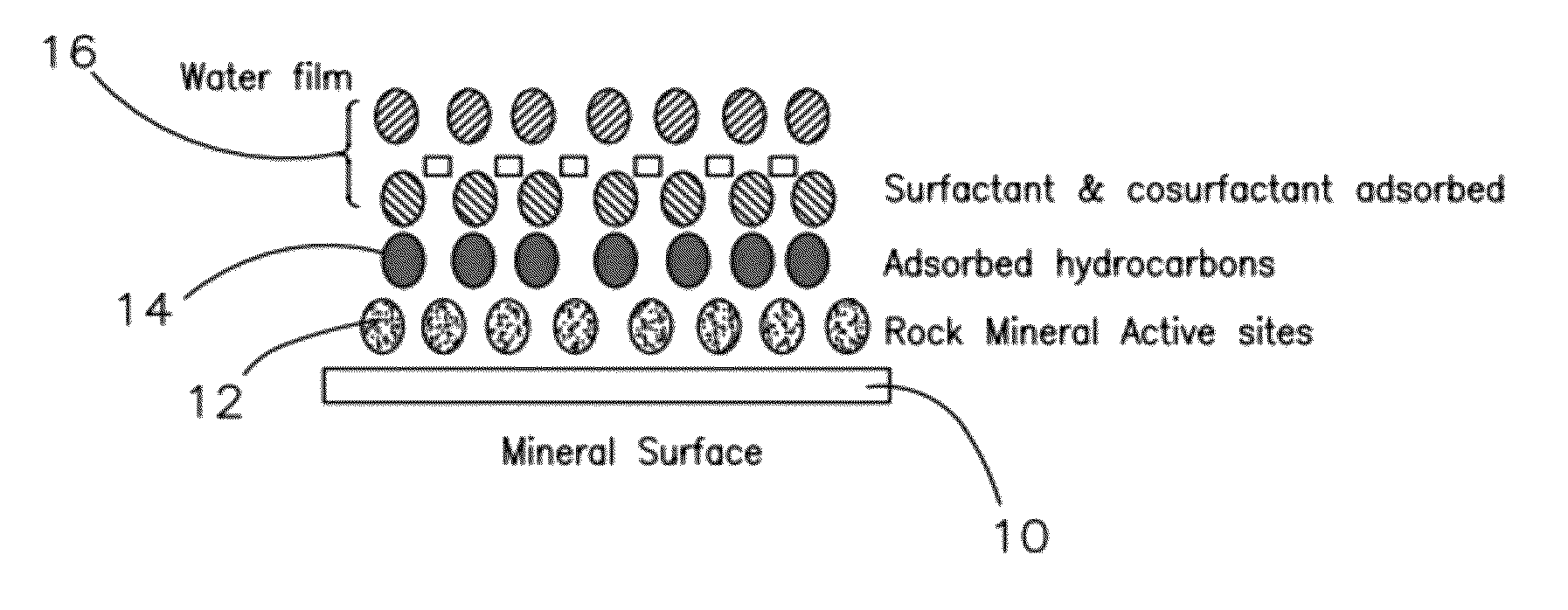

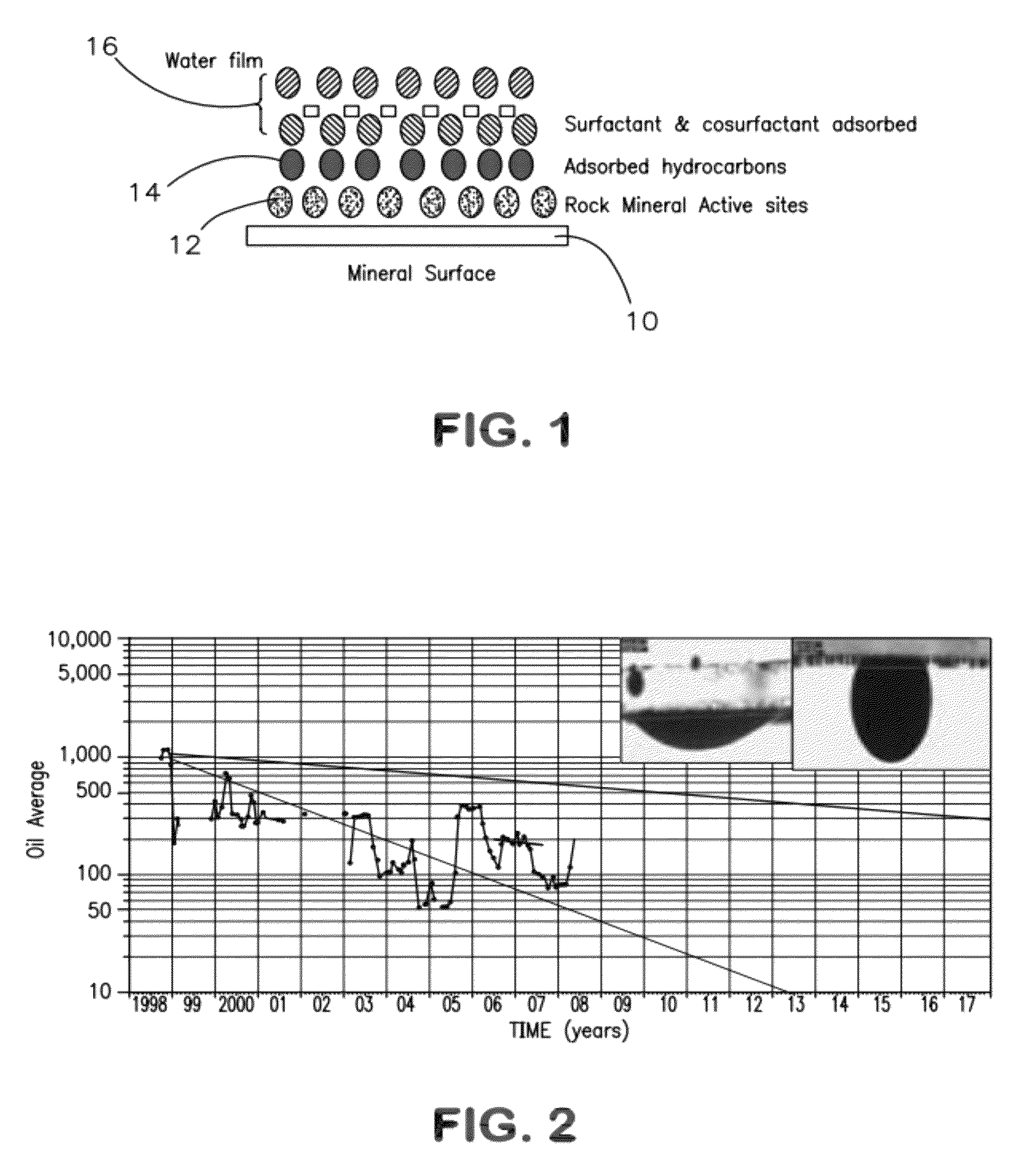

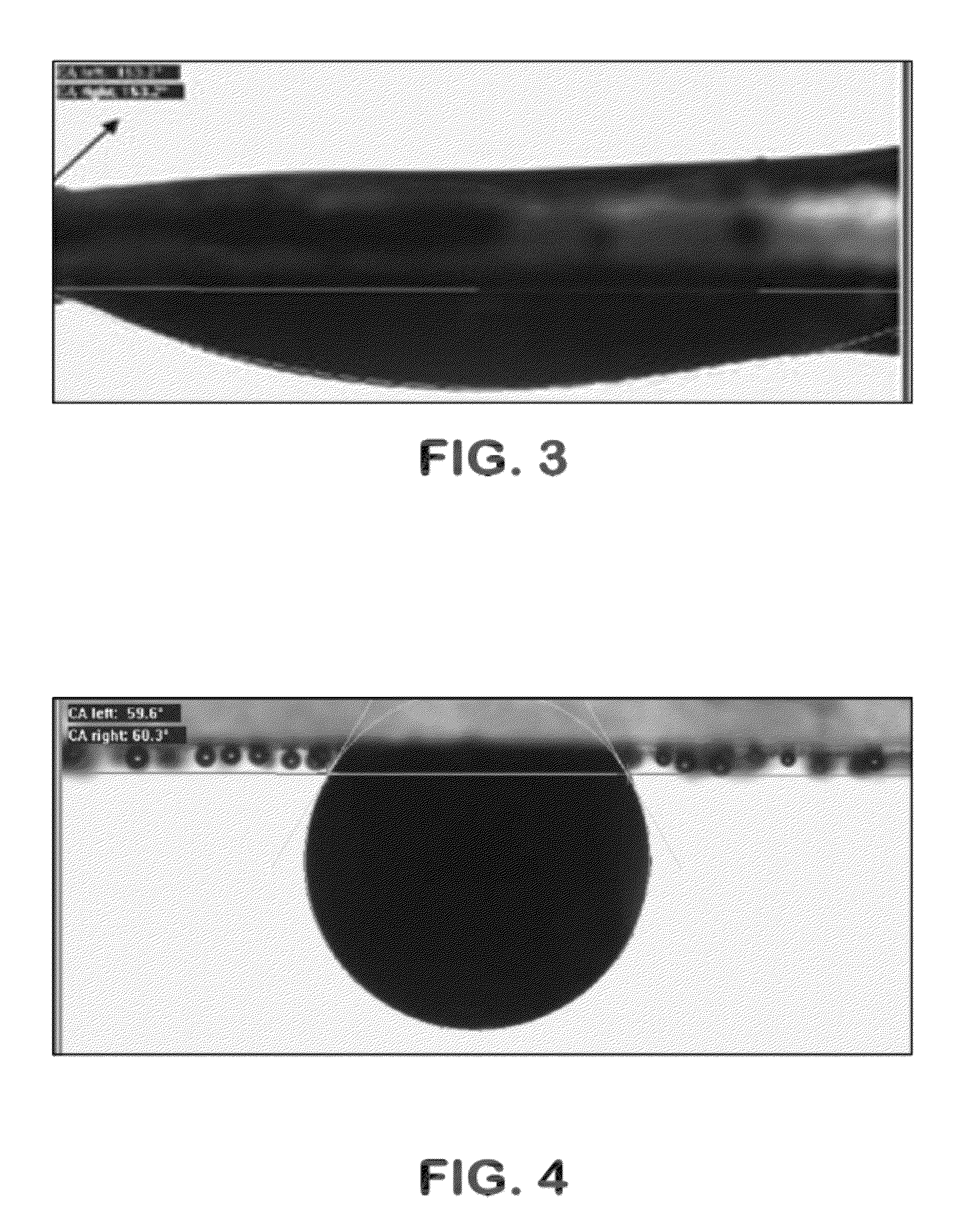

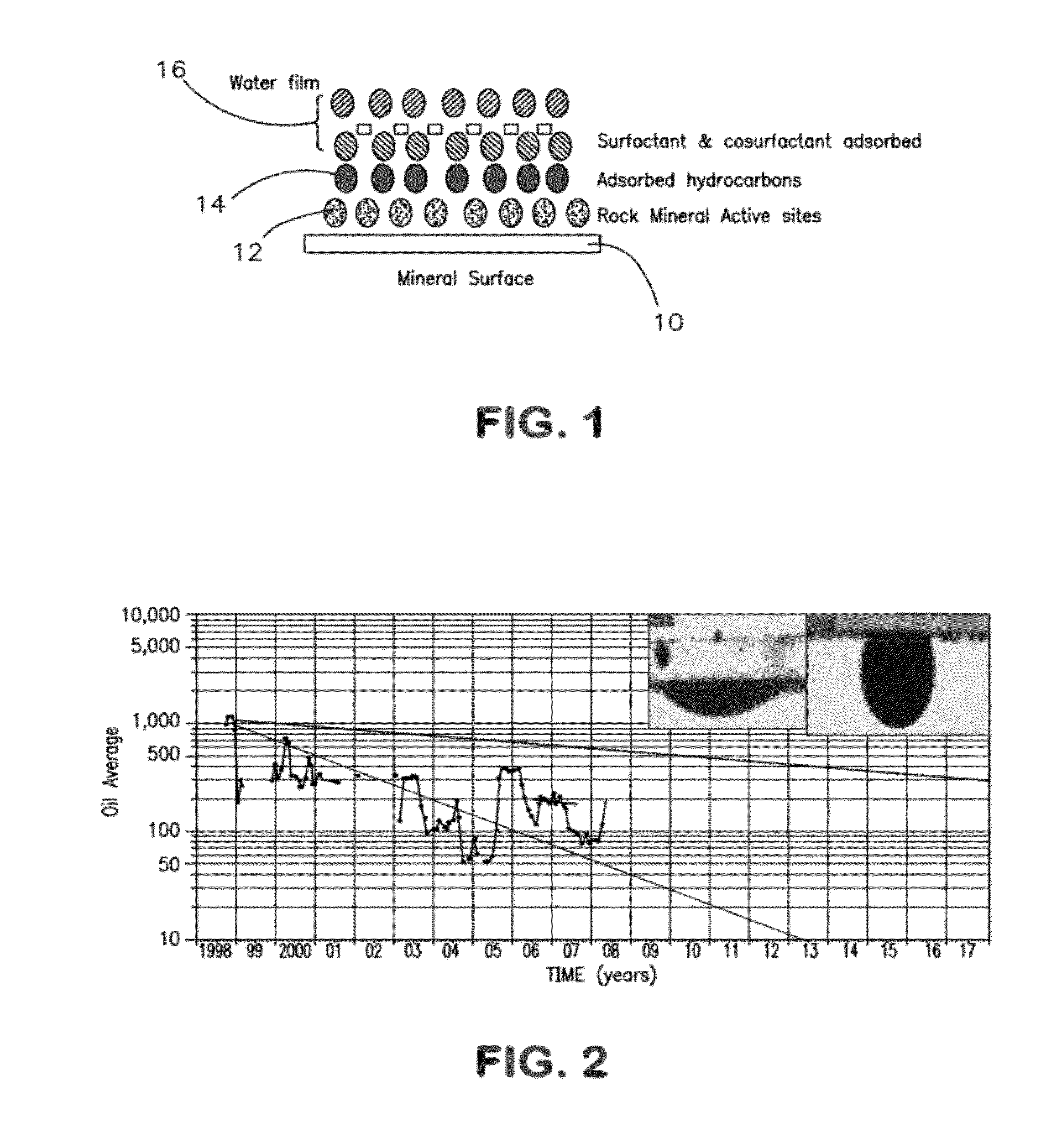

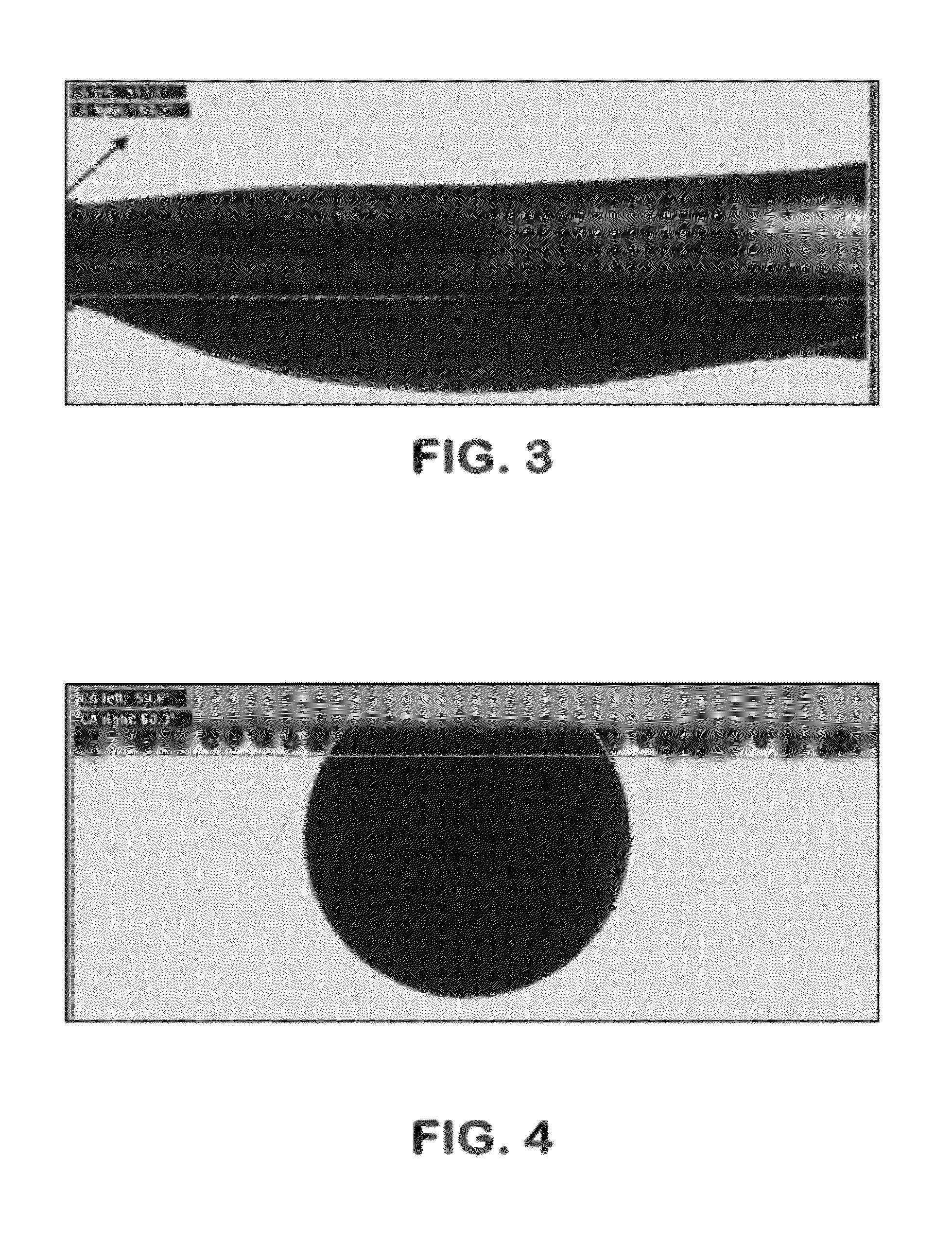

Formulation and method of use for exploitation and transport of heavy and extra heavy oil wells

Combined injection, production and transportation method for a production well and an injection well of a hydrocarbon-bearing formation and flow line system for surface transportation of a product stream includes introducing a mixture of surfactant, co-surfactant and carrier fluid into each of the wells so that the mixture flows into porous media surrounding the wells; holding the reservoir mixture in the production well in the presence of water for a time sufficient to form water film on surfaces of the porous media surrounding the production well; injecting injection fluid into the injection well while producing from the production well, whereby hydrocarbons flow from the porous media around the injection well toward the production well, introducing an injection mixture of a surfactant and carrier fluid into a desired point in tubing of the production well so that the tubing injection mixture mixes with the production stream forming an emulsion, and producing the emulsion.

Owner:INTREVEP SA

High speed filtration device using porous media, and backwash method thereof

InactiveUS9149746B2Enhance effective removalConstant efficiencyGeneral water supply conservationSpecific water treatment objectivesFiltrationWater flow

The present invention relates to a porous media-mediated high speed filtration device for easy backwash, wherein the inflow water to be filtered is guided to an upper portion of the high speed filtration device and is filtered by downflow and porous media are backwashed for maintaining optimum filter efficiency by blocking the flow of inflow water and water to be treated after sensing the level of the inflow water or the change in the flux of the water to be treated, supplying backwash water and / or air by upflow through a backwash equipment to separate pollutants in the porous media by the collision and friction between the porous media by flowing of the porous media through the stream of the backwash water, placing the porous media in a stationary location, and discharging the pollutants through a discharge pipe of the high speed filtration device before the pollutants settle. In addition, the present invention comprises a backwash method of the high speed filtration device using porous media.

Owner:SUNG PIL CHOI

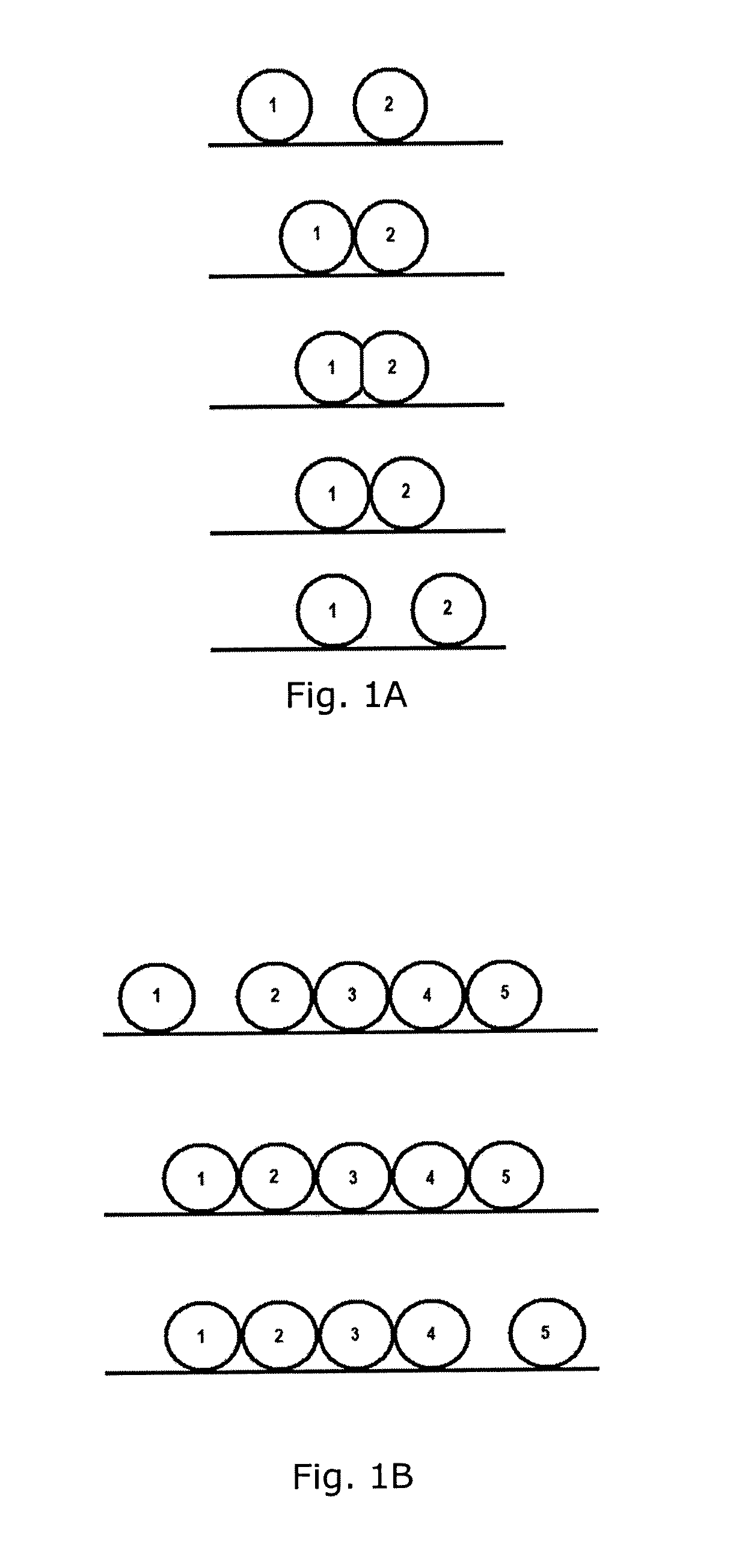

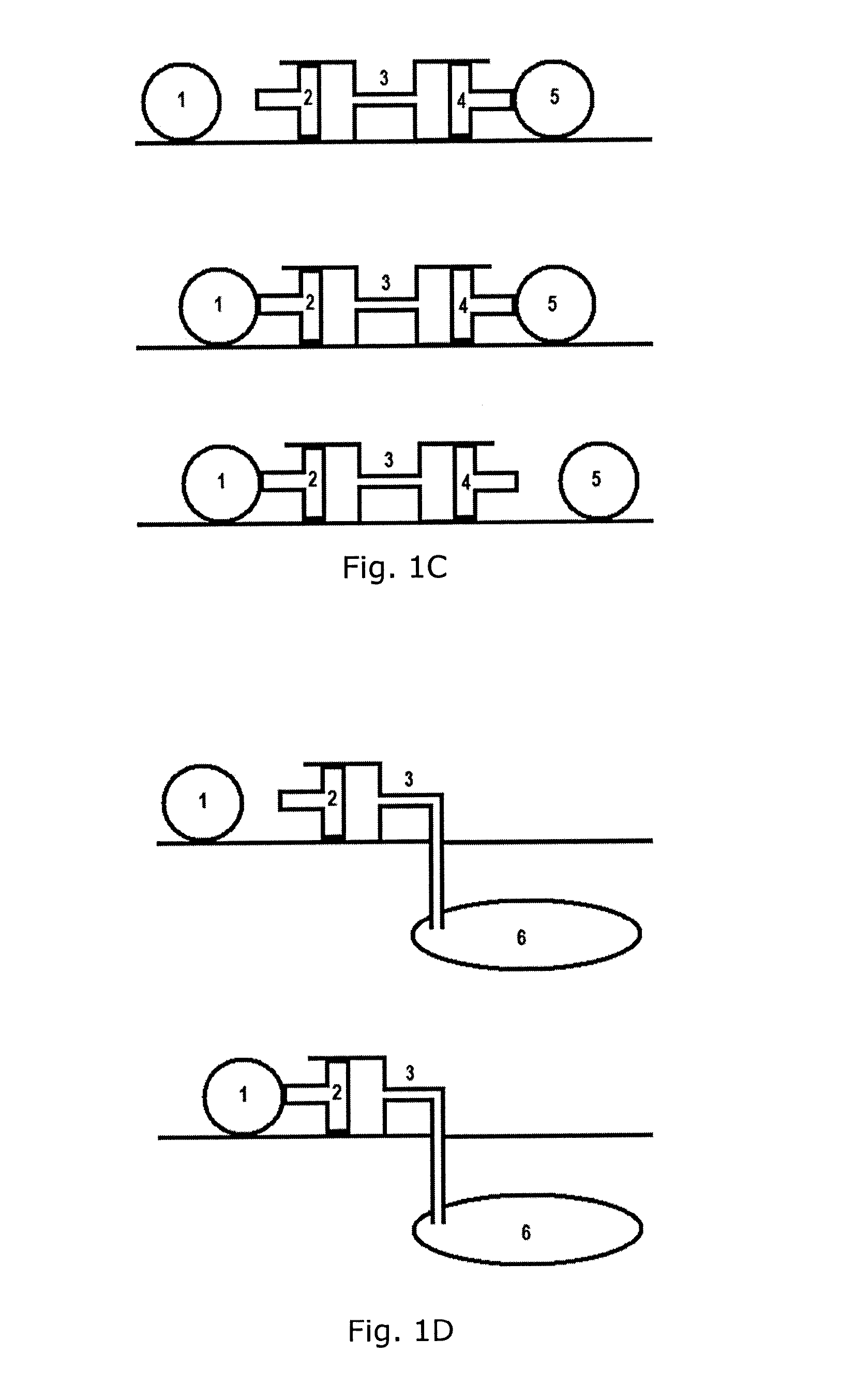

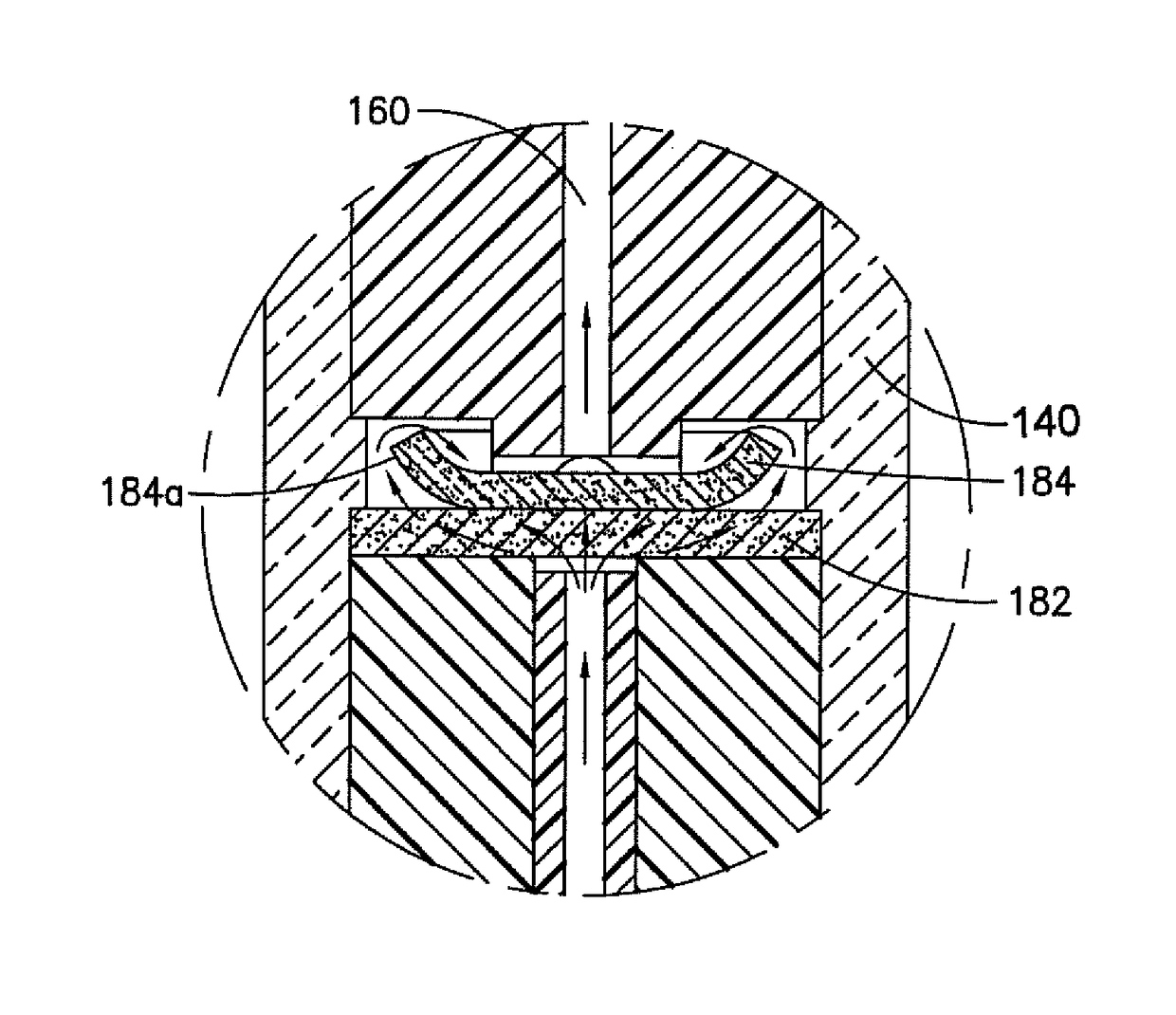

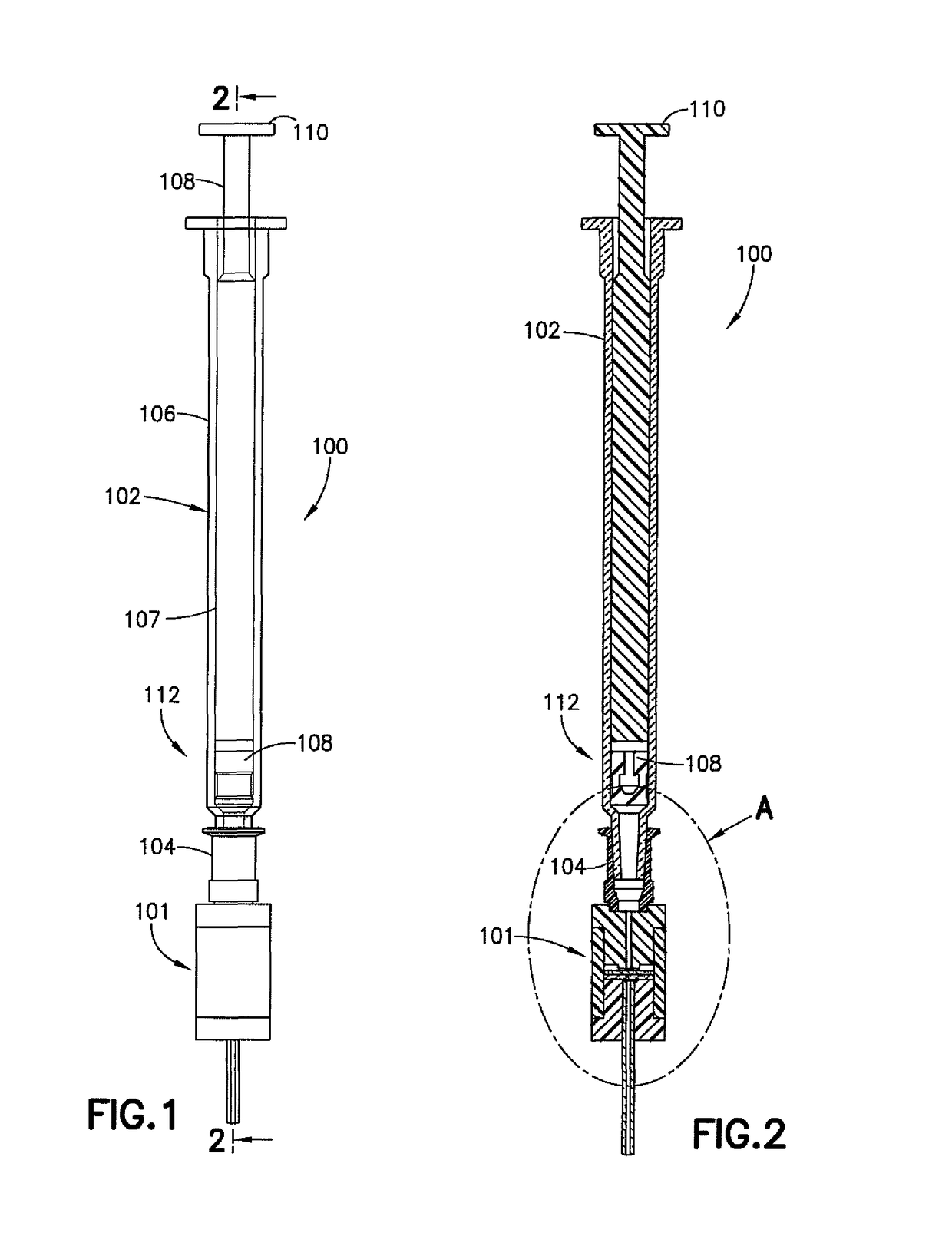

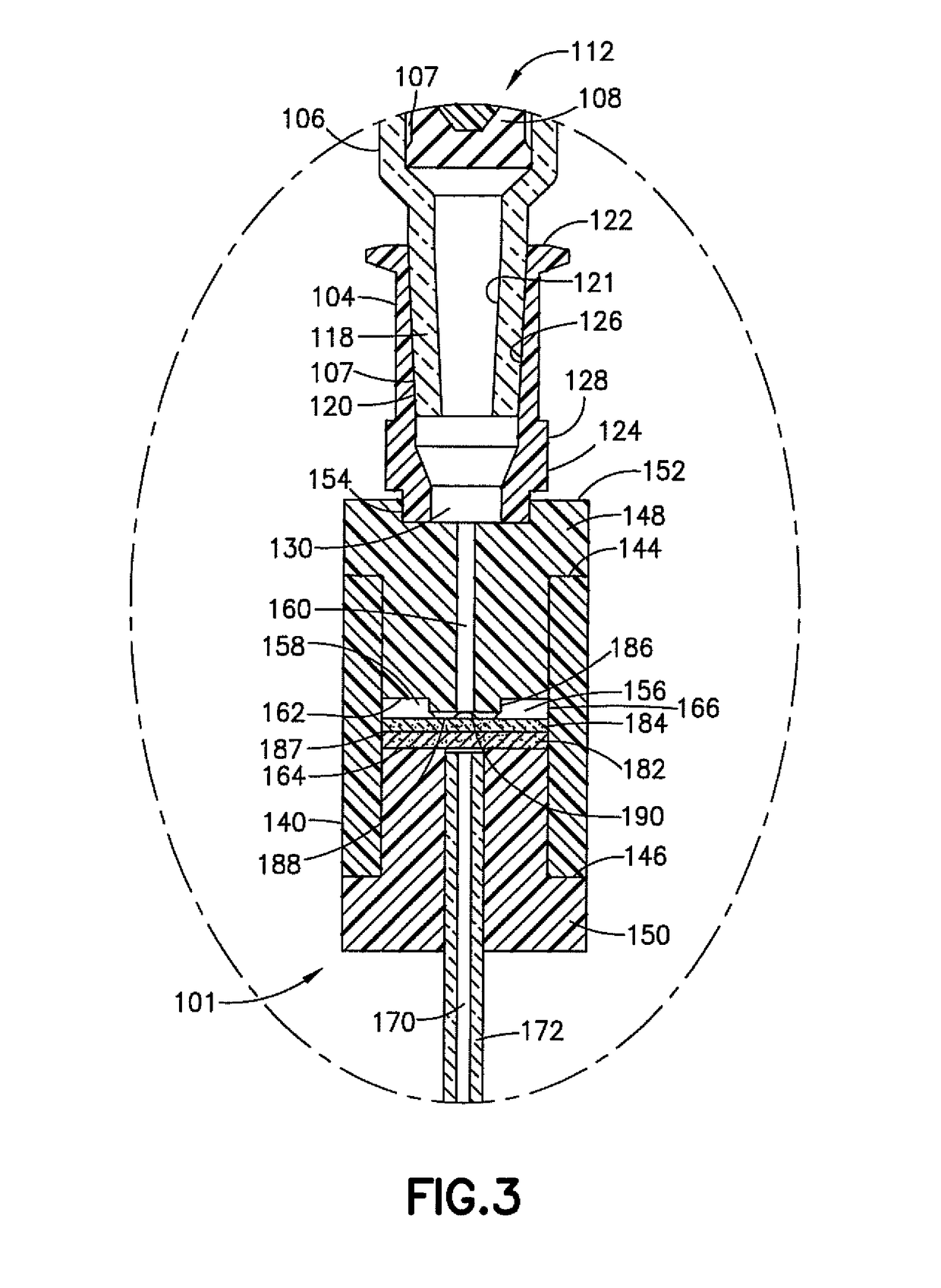

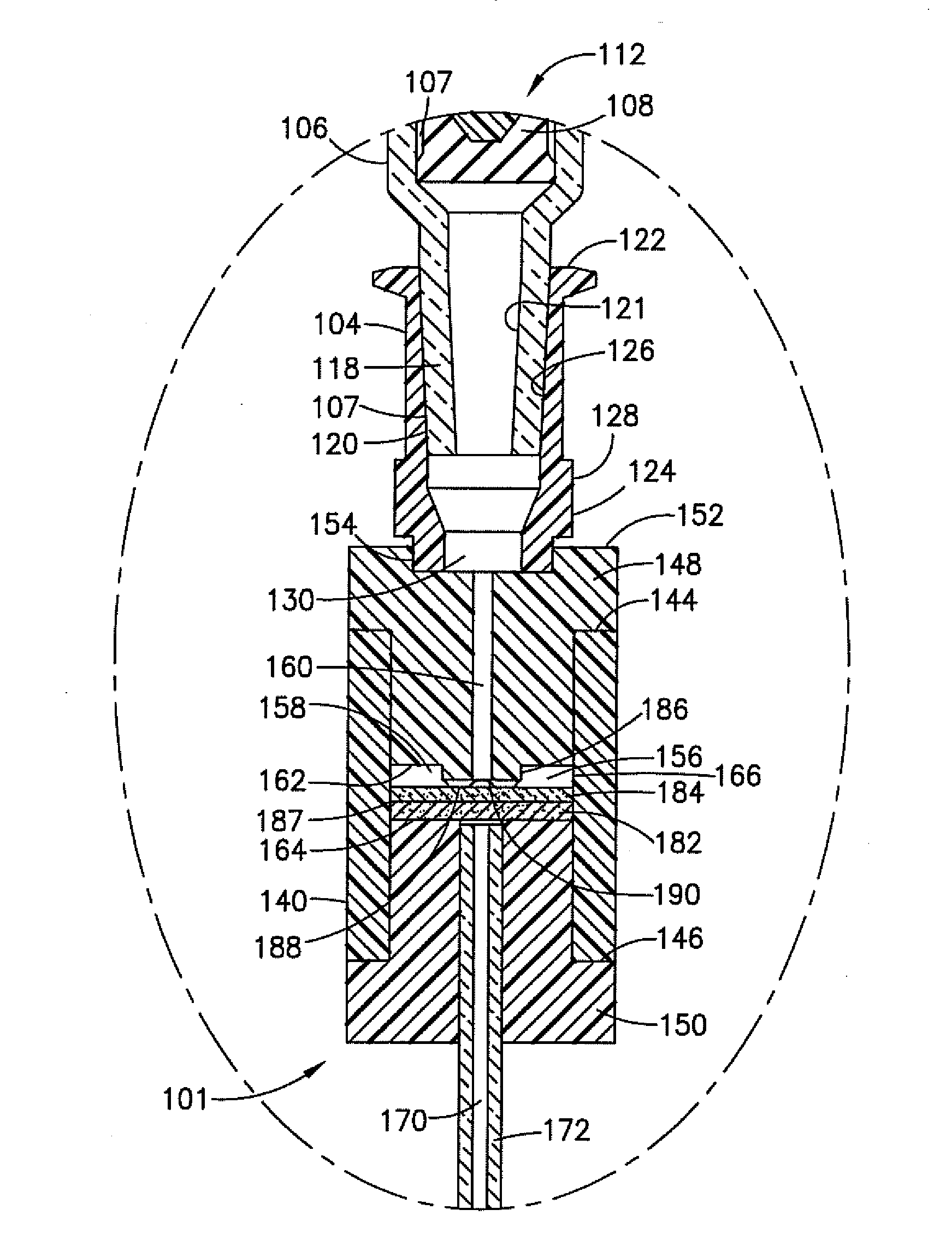

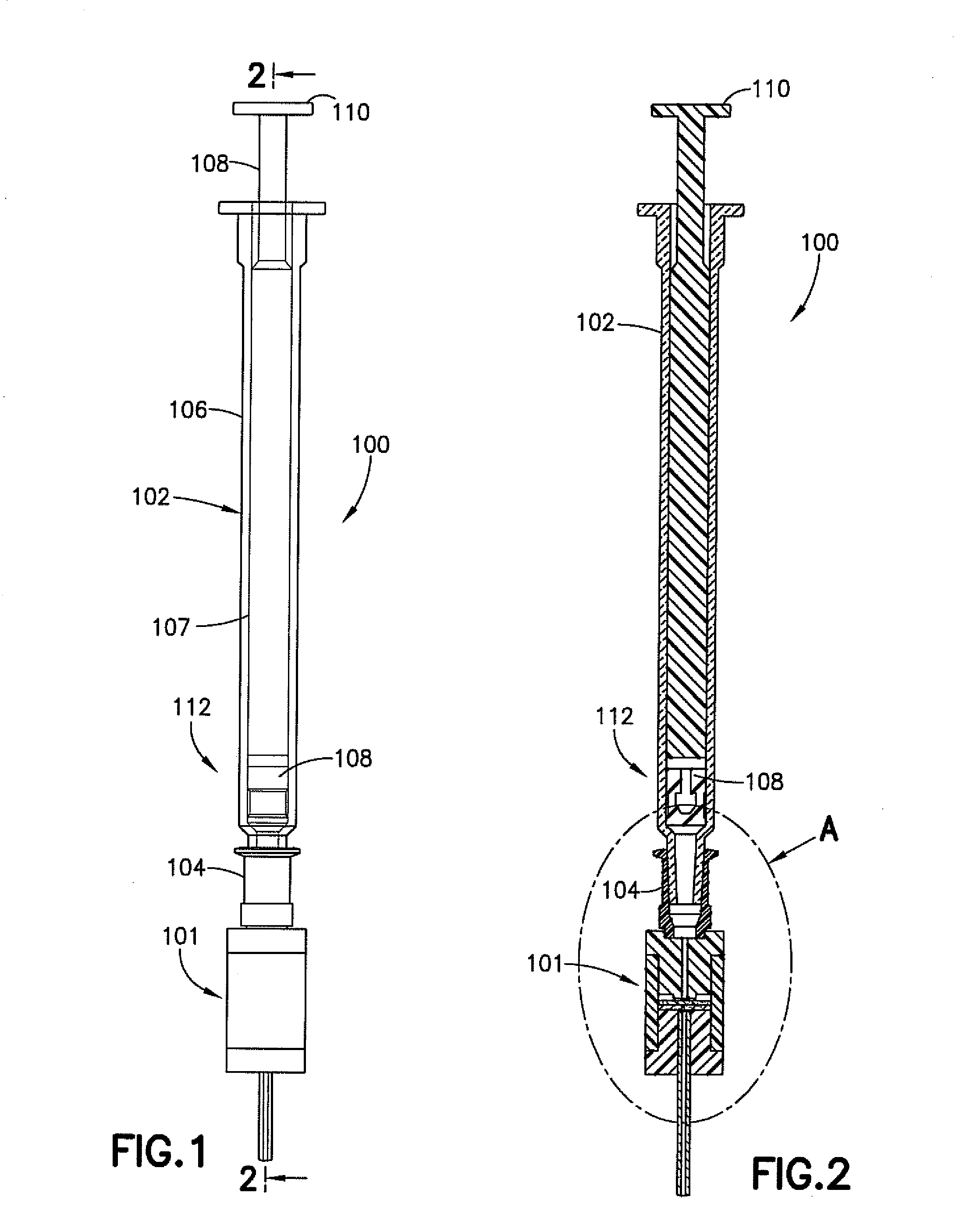

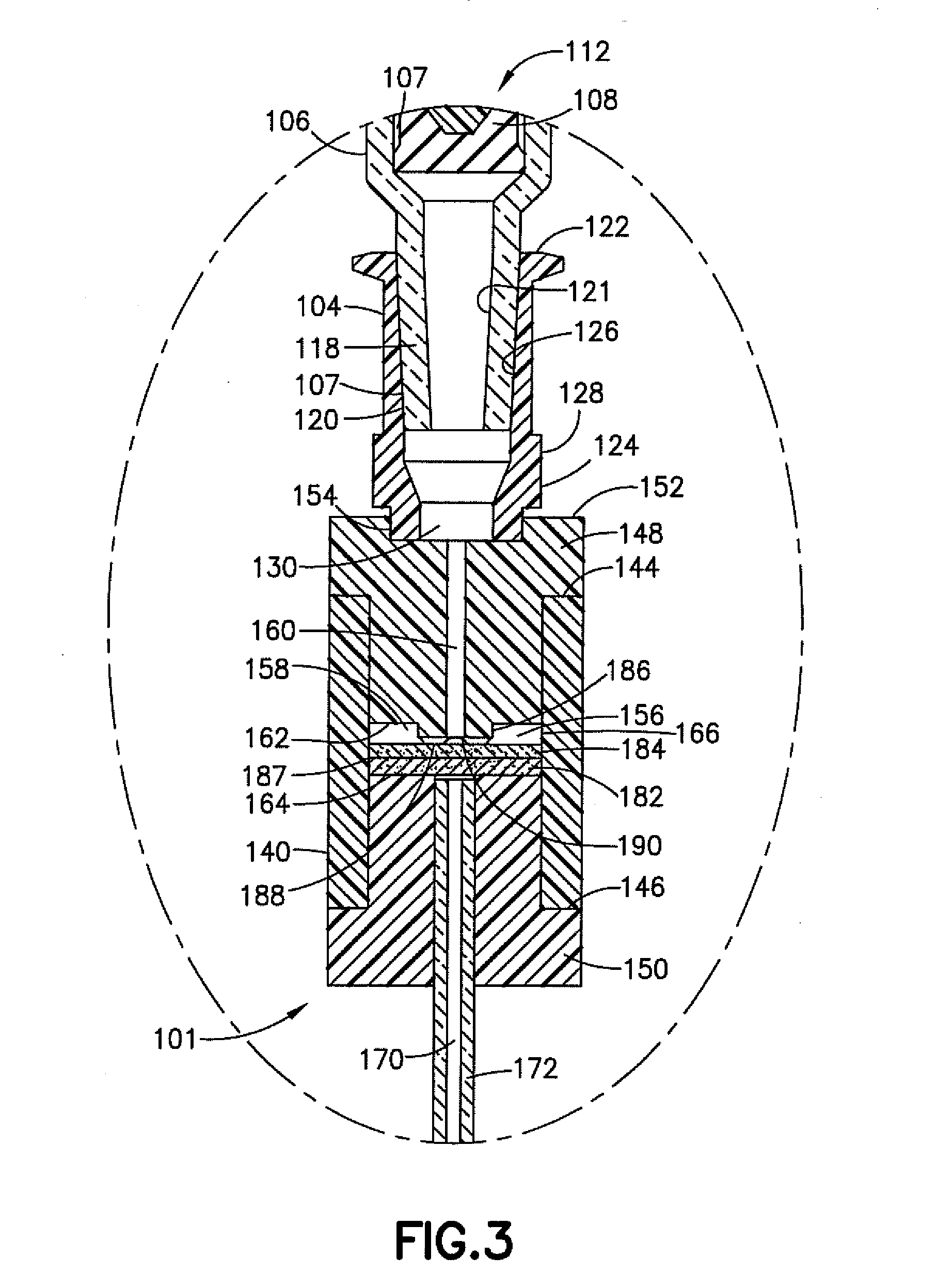

Sample extraction and preparation device

ActiveUS9926553B2Inexpensive and rapid for capturingBurettes/pipettesDNA preparationMedicineEngineering

A fluid sample extraction device is disclosed comprising a housing defining an internal fluid passage having a distal open end and a proximal open end and a porous medium within the fluid passage, between the distal open end and proximal open end. The porous medium, which may be glass, is configured to allow fluid flow in the fluid passage to flow around the porous medium, toward the proximal open end of the housing, when fluid is drawn from the distal open end toward the proximal open end, and to allow fluid in the fluid passage to flow toward the distal open end of the housing, through the porous medium when the fluid is forced toward the distal open end. The porous medium is also configured to capture nucleic acids in the porous medium from the fluid when fluid is forced through the porous medium. Devices and kits are also disclosed.

Owner:BIOMEME

Sample extraction and preparation device

ActiveUS20150126724A1Inexpensive and rapid for capturingSugar derivativesLaboratory glasswaresEngineeringSample extraction

A fluid sample extraction device is disclosed comprising a housing defining an internal fluid passage having a distal open end and a proximal open end and a porous medium within the fluid passage, between the distal open end and proximal open end. The porous medium, which may be glass, is configured to allow fluid flow in the fluid passage to flow around the porous medium, toward the proximal open end of the housing, when fluid is drawn from the distal open end toward the proximal open end, and to allow fluid in the fluid passage to flow toward the distal open end of the housing, through the porous medium when the fluid is forced toward the distal open end. The porous medium is also configured to capture nucleic acids in the porous medium from the fluid when fluid is forced through the porous medium. Devices and kits are also disclosed.

Owner:BIOMEME

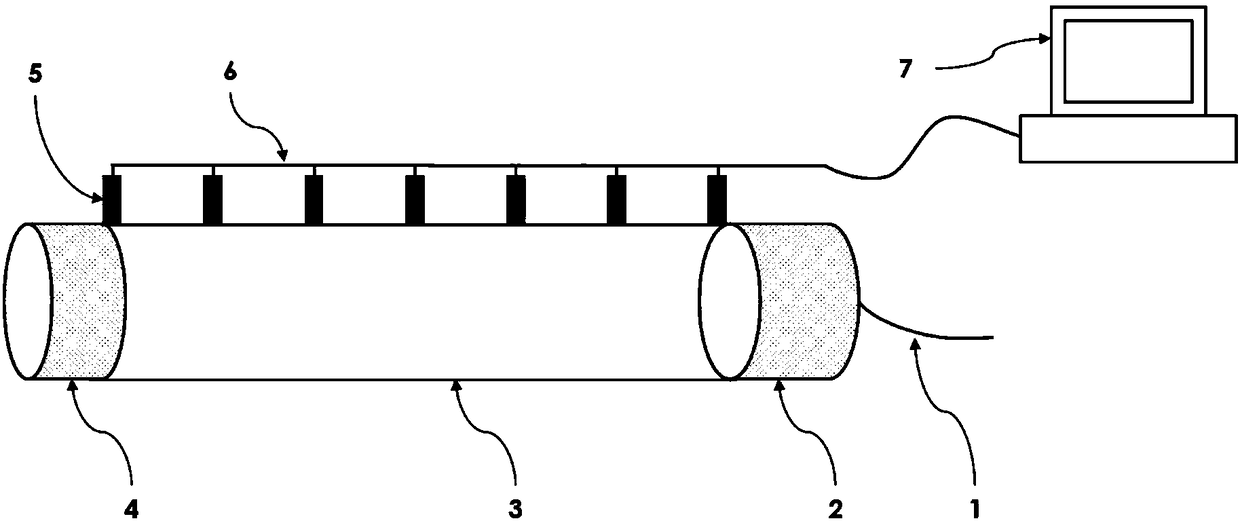

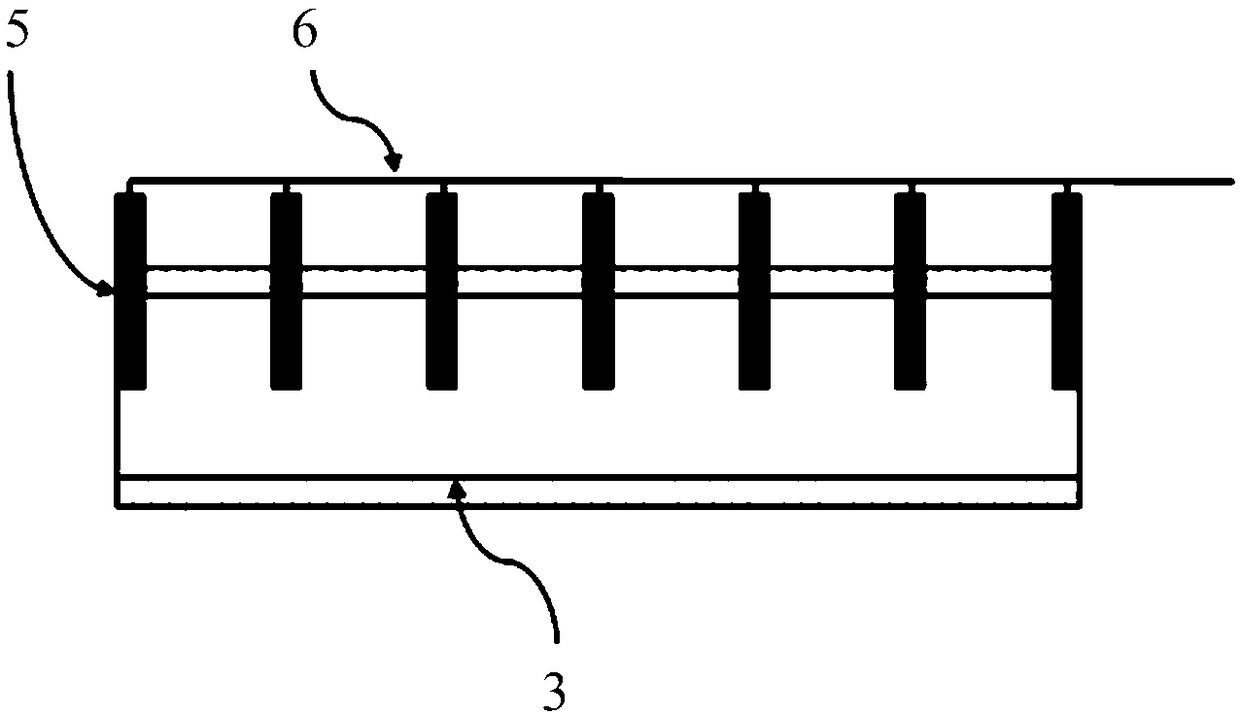

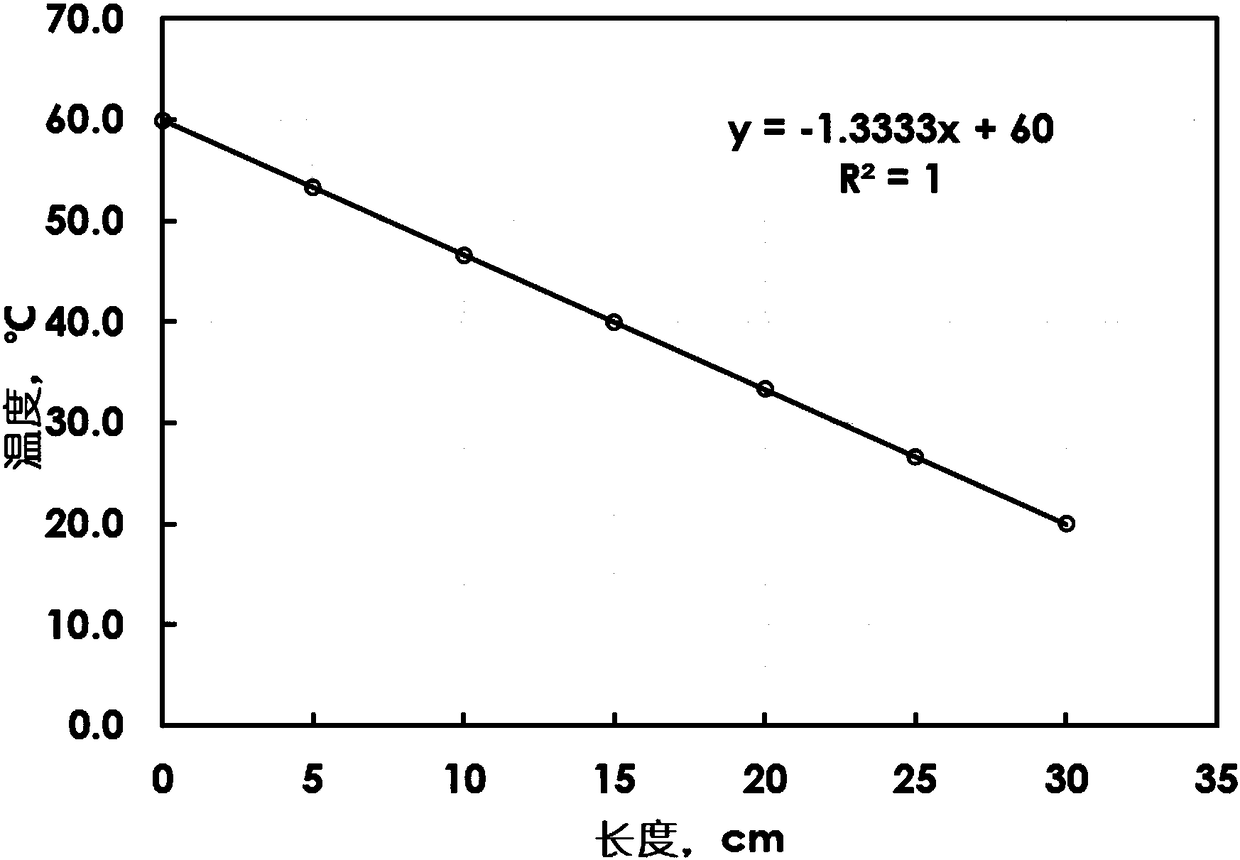

Porous medium fluid seepage simulation system and porous medium fluid seepage simulation method

ActiveCN108226004ASimple structureMaterial heat developmentPermeability/surface area analysisThermal insulationHeat conducting

The embodiment of the application provides a porous medium fluid seepage simulation system and a porous medium fluid seepage simulation method. The system comprises a sealed thermal insulation container, a heat source, a plurality of temperature sensors, and a data processing device; heat-conducting medium for simulating fluid in porous medium to be simulated fills the sealed thermal insulation container; the heat source is used for supplying heat energy to the heat-conducting medium; the plurality of temperature sensors are used for keeping the constant heat output of the heat source, and when temperature data which are acquired by the plurality of temperature sensors at the same sampling time are in a linear relation, temperature data of the heat-conducting medium at different positionsin the sealed thermal insulation container are acquired; the data processing device is used for determining seepage parameters of the porous medium to be simulated according to the temperature data and a preset similarity proportion coefficient; and the similarity proportion coefficient is a proportion coefficient between heat transfer parameter and similar seepage parameter. The embodiment of theapplication is simple in structure and low in cost.

Owner:PETROCHINA CO LTD

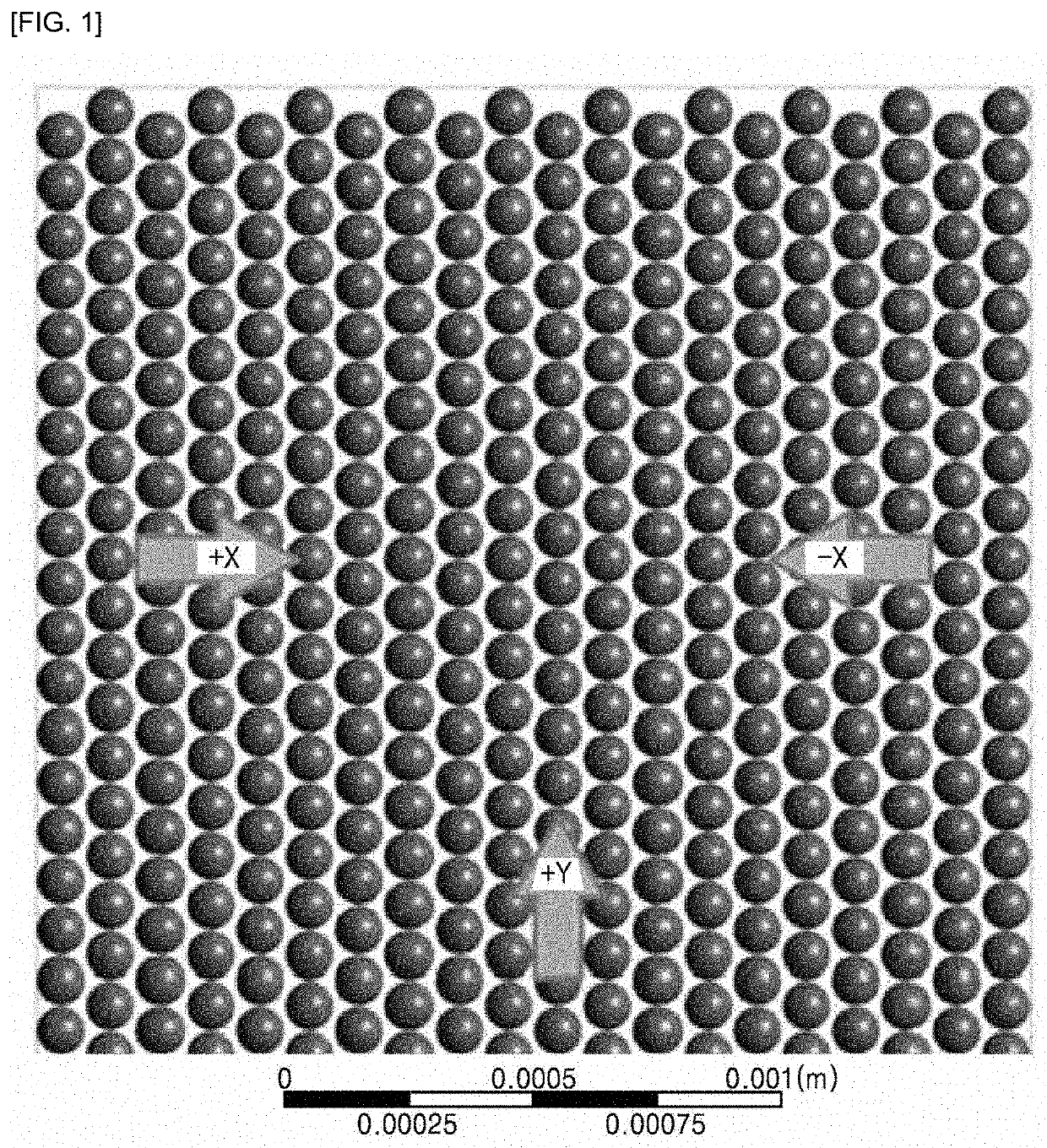

Method for calculating tortuous hydraulic diameter of porous medium and method for analyzing flow in porous medium using same

ActiveUS20200025668A1Reduce error rateLarge error ratePermeability/surface area analysisStrength propertiesFriction lossEngineering

Provided is a method of calculating a tortuous hydraulic diameter of a porous medium for laminar flow and turbulent flow considering a geometric feature and a friction loss feature. A method of calculating a tortuous hydraulic diameter of a porous medium, according to an embodiment of the present invention, includes providing porosity and a specific surface area of a porous medium, calculating a hydraulic diameter of the porous medium by using the porosity and the specific surface area, calculating tortuosity of the porous medium, and calculating a tortuous hydraulic diameter corresponding to a function of tortuosity, by using the hydraulic diameter and the tortuosity of the porous medium.

Owner:KOREA GAS CORPORATION

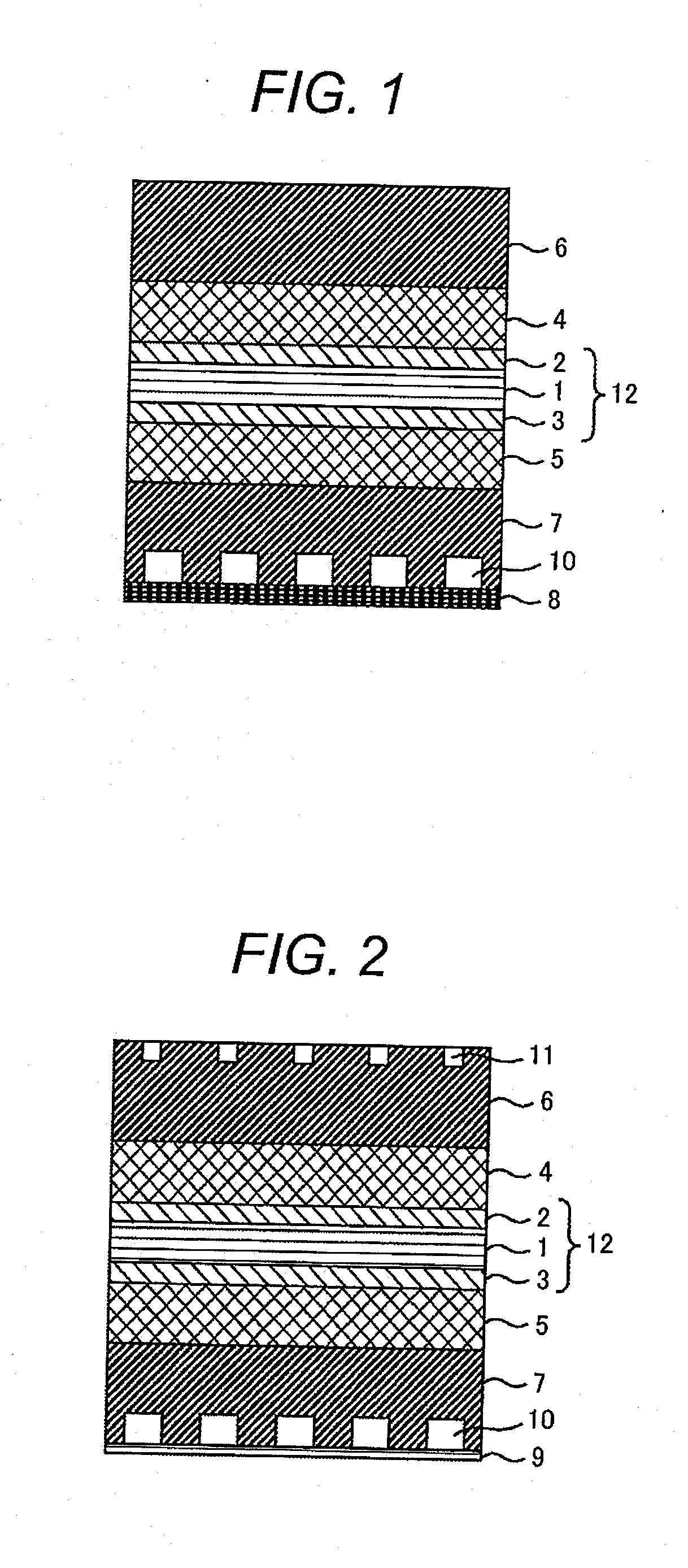

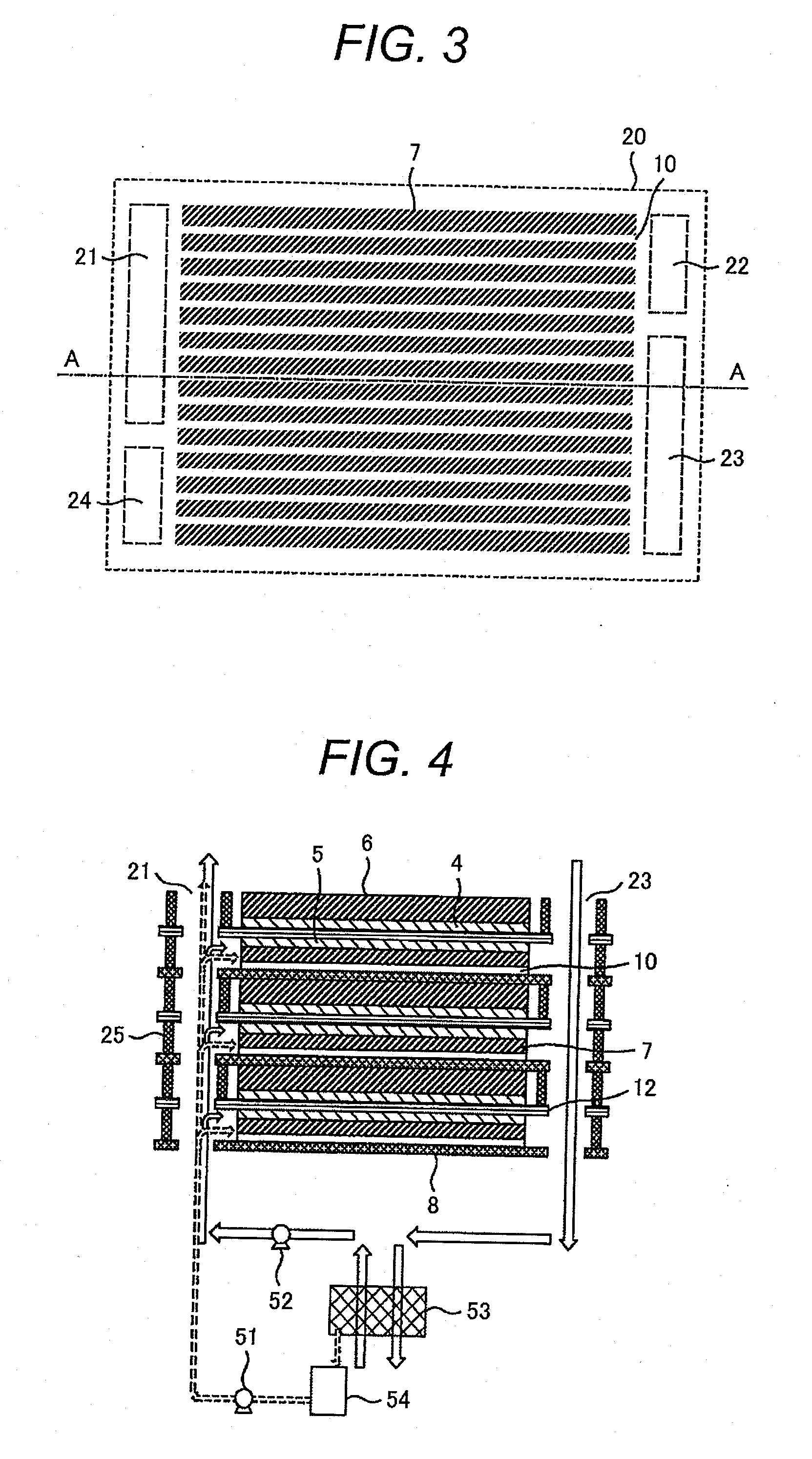

Proton exchange membrane fuel cell stack

InactiveUS20110229787A1Simple cooling structureDownsizing the fuel cell stackFuel cells groupingFuel cell auxillariesLiquid waterEngineering

A proton exchange membrane fuel cell stack comprises a plurality of stacked unit cells, the unit cells each including: a membrane electrode assembly; an anode side-conductive gas diffusion layer and an anode side-fuel gas flow field to feed a fuel gas to an anode of the membrane electrode assembly; and a cathode side-conductive gas diffusion layer and a cathode side-oxidant gas flow field to feed an oxidant gas to a cathode of the membrane electrode assembly; and a bipolar plate for separating between the anode side-fuel flow field and the cathode side-oxidant gas flow field. Then, the fuel gas flow field and the oxidant gas flow field are constituted by respective porous media flow fields each which is a conductive porous medium, and the porous media flow field for the oxidant gas flow field is configured so that liquid water is supplied mixedly together with the oxidant gas thereto.

Owner:HITACHI LTD

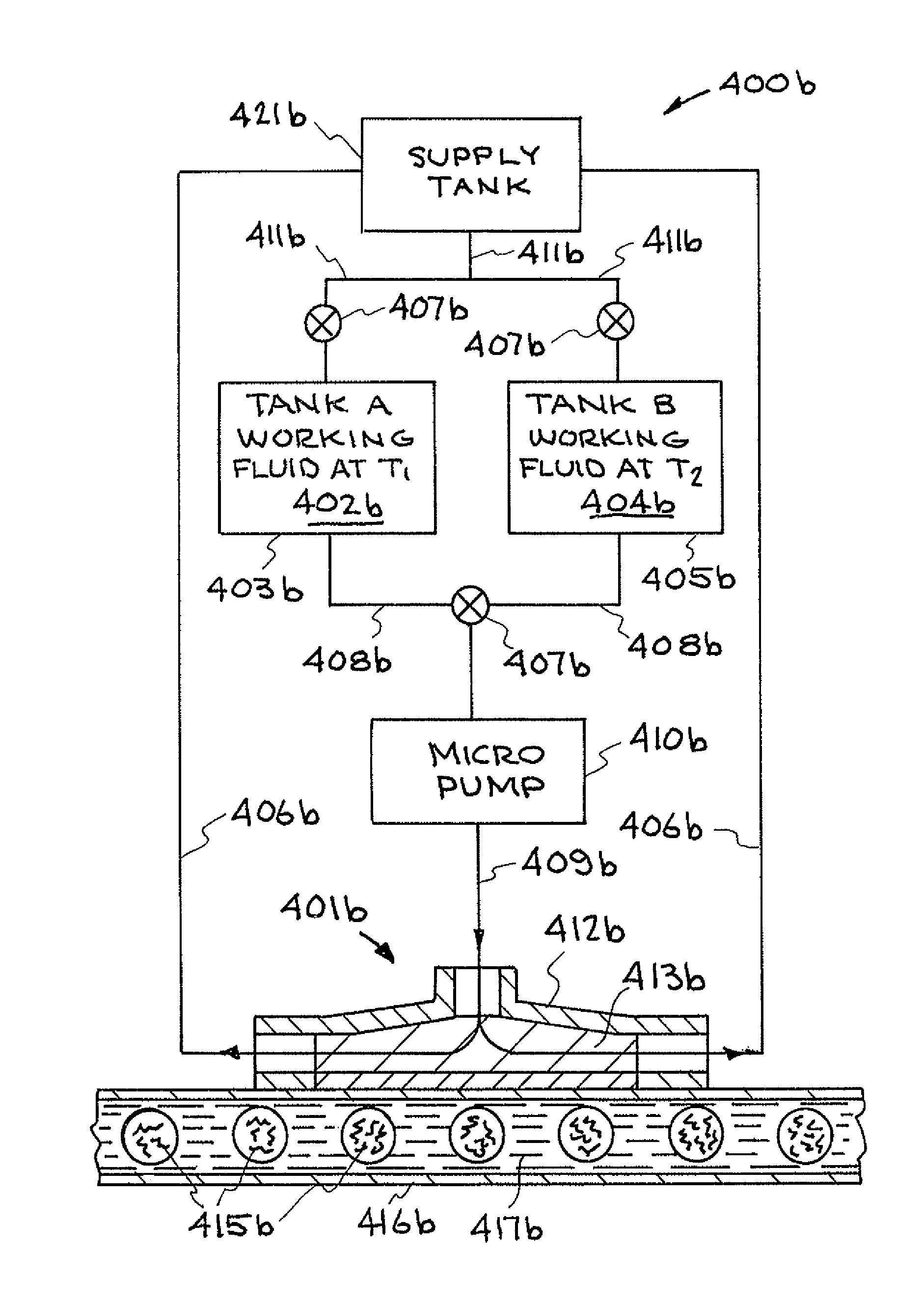

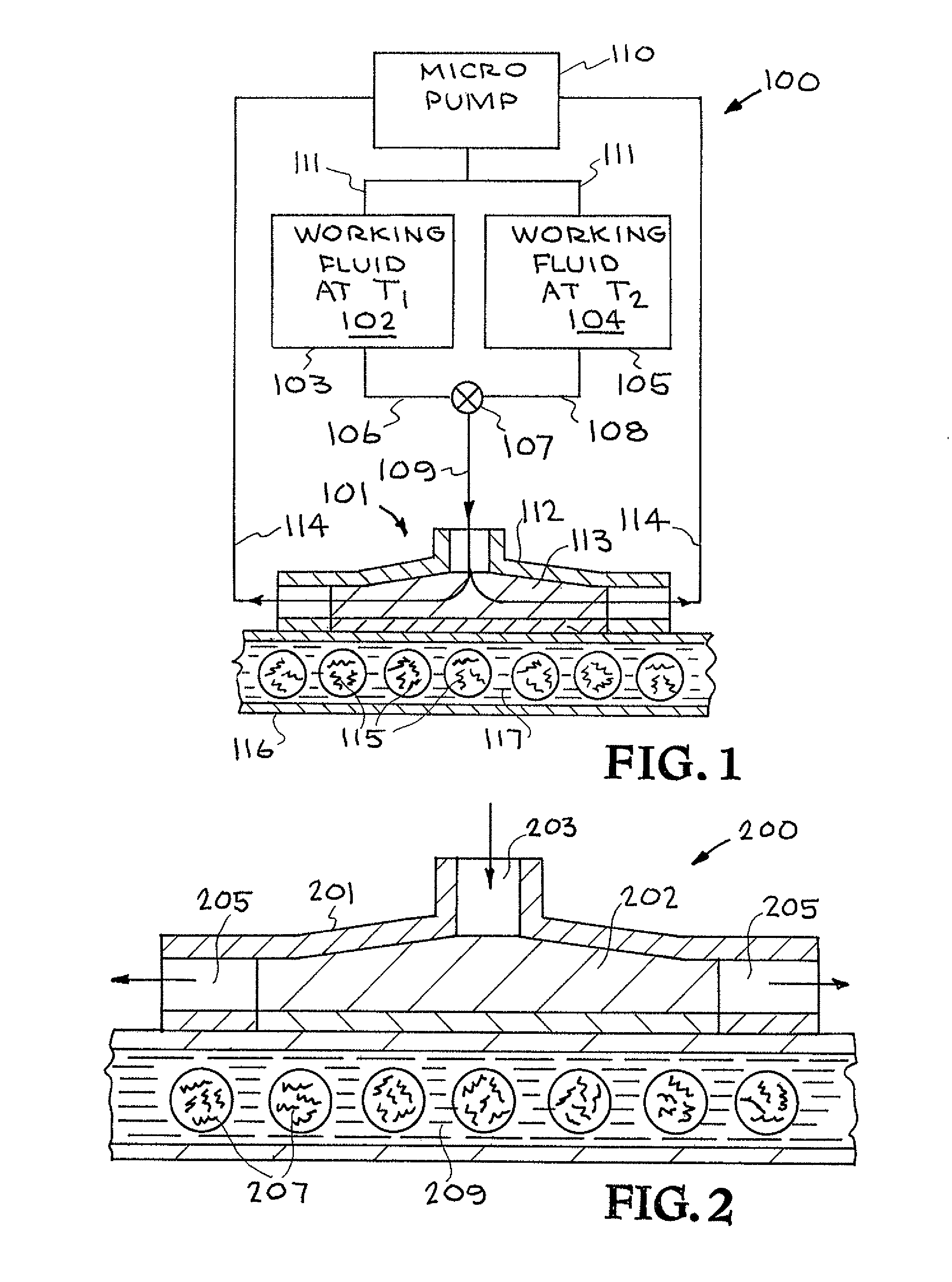

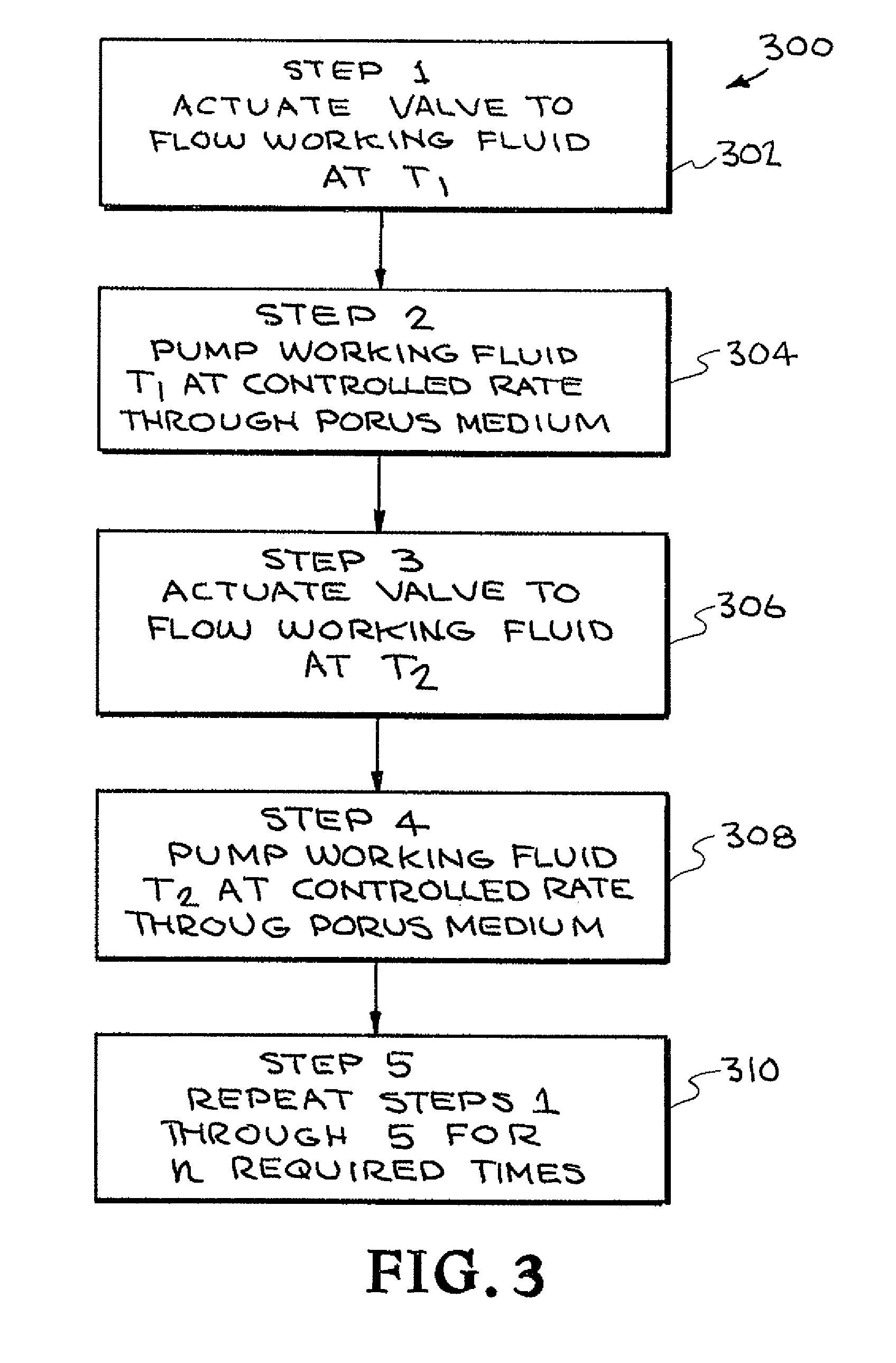

Rapid microfluidic thermal cycler for nucleic acid amplification

ActiveUS9170060B2Bioreactor/fermenter combinationsBiological substance pretreatmentsWorking fluidEngineering

A system for thermal cycling a material to be thermal cycled including a microfluidic heat exchanger; a porous medium in the microfluidic heat exchanger; a microfluidic thermal cycling chamber containing the material to be thermal cycled, the microfluidic thermal cycling chamber operatively connected to the microfluidic heat exchanger; a working fluid at first temperature; a first system for transmitting the working fluid at first temperature to the microfluidic heat exchanger; a working fluid at a second temperature, a second system for transmitting the working fluid at second temperature to the microfluidic heat exchanger; a pump for flowing the working fluid at the first temperature from the first system to the microfluidic heat exchanger and through the porous medium; and flowing the working fluid at the second temperature from the second system to the heat exchanger and through the porous medium.

Owner:RGT UNIV OF CALIFORNIA +1

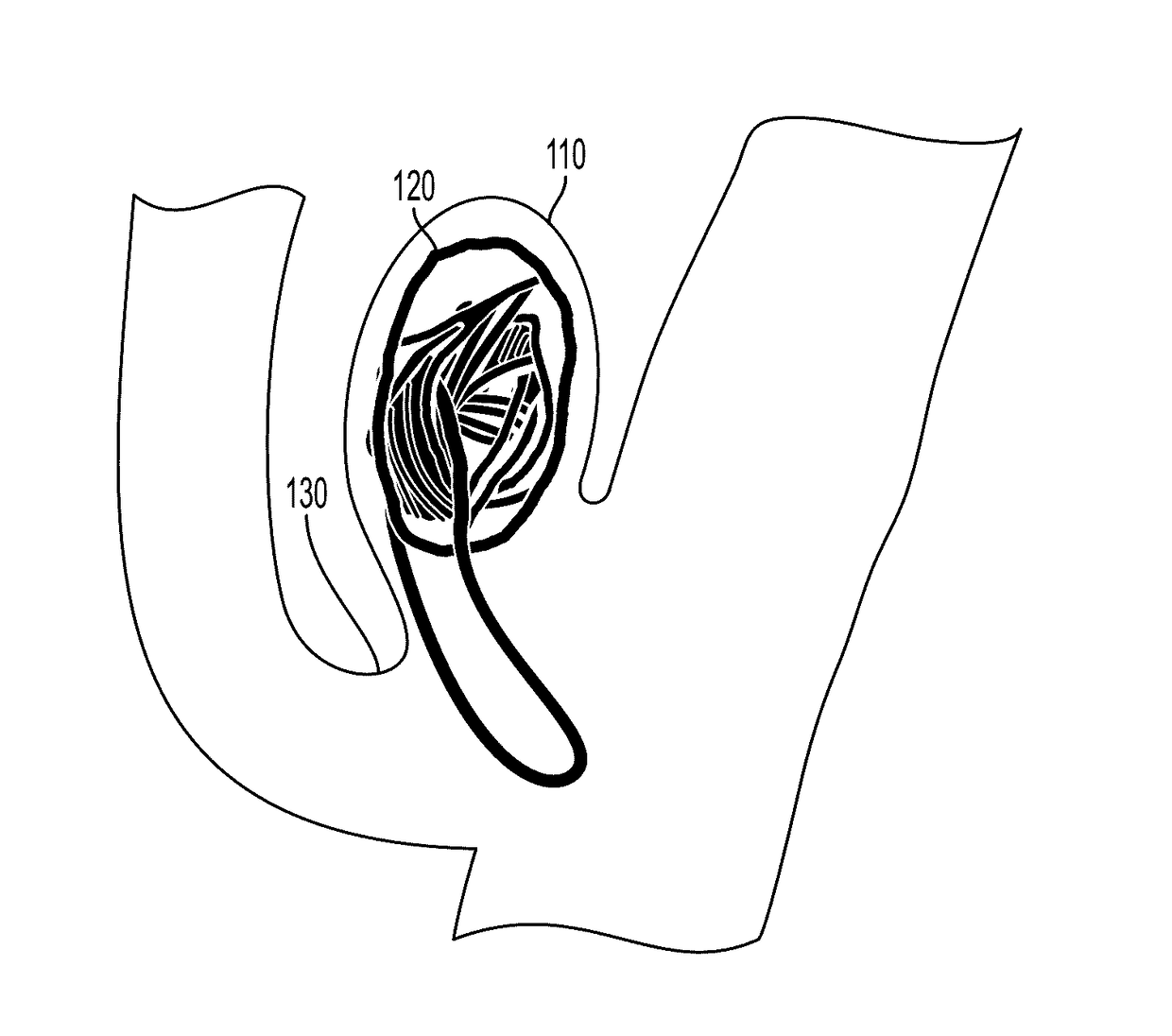

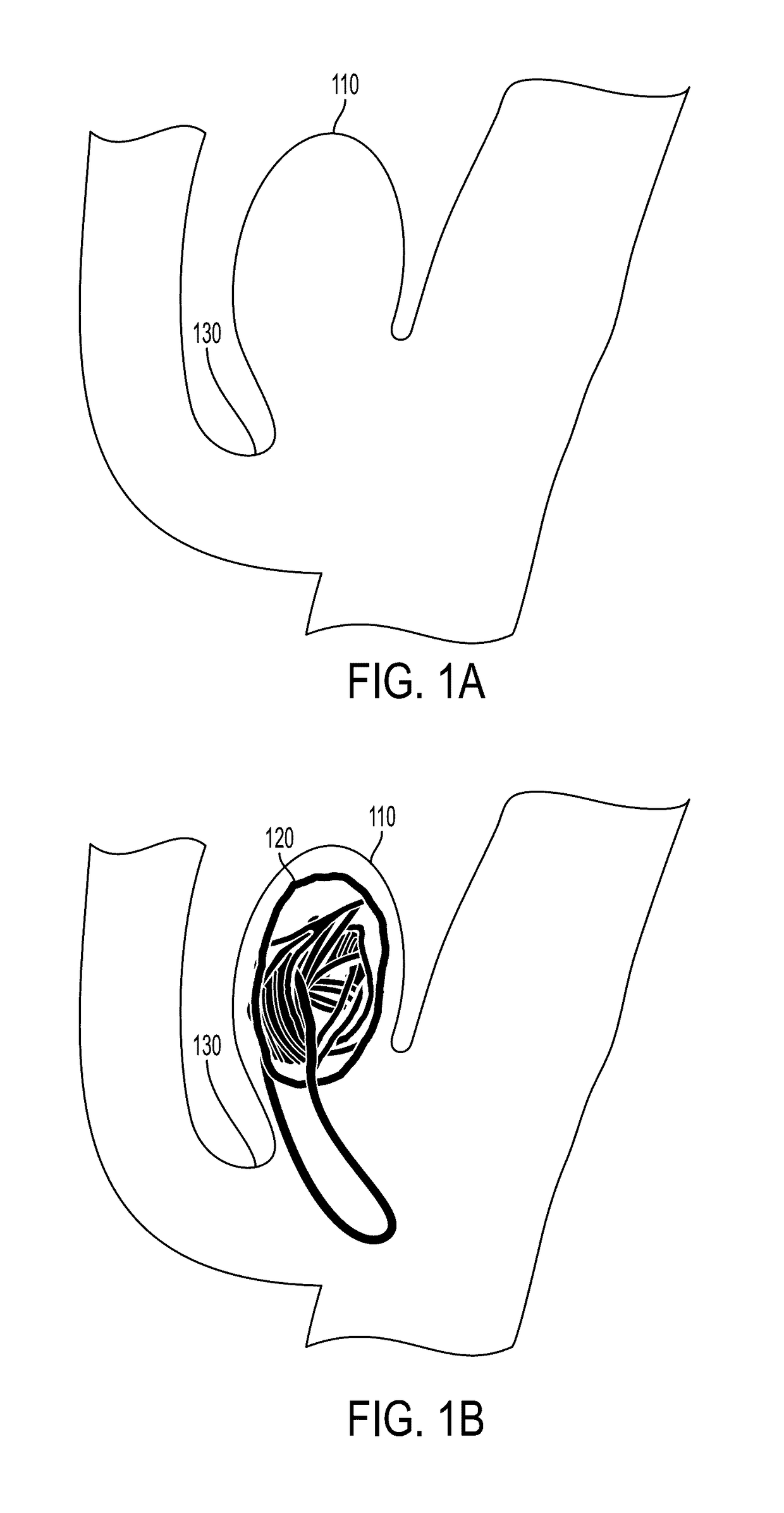

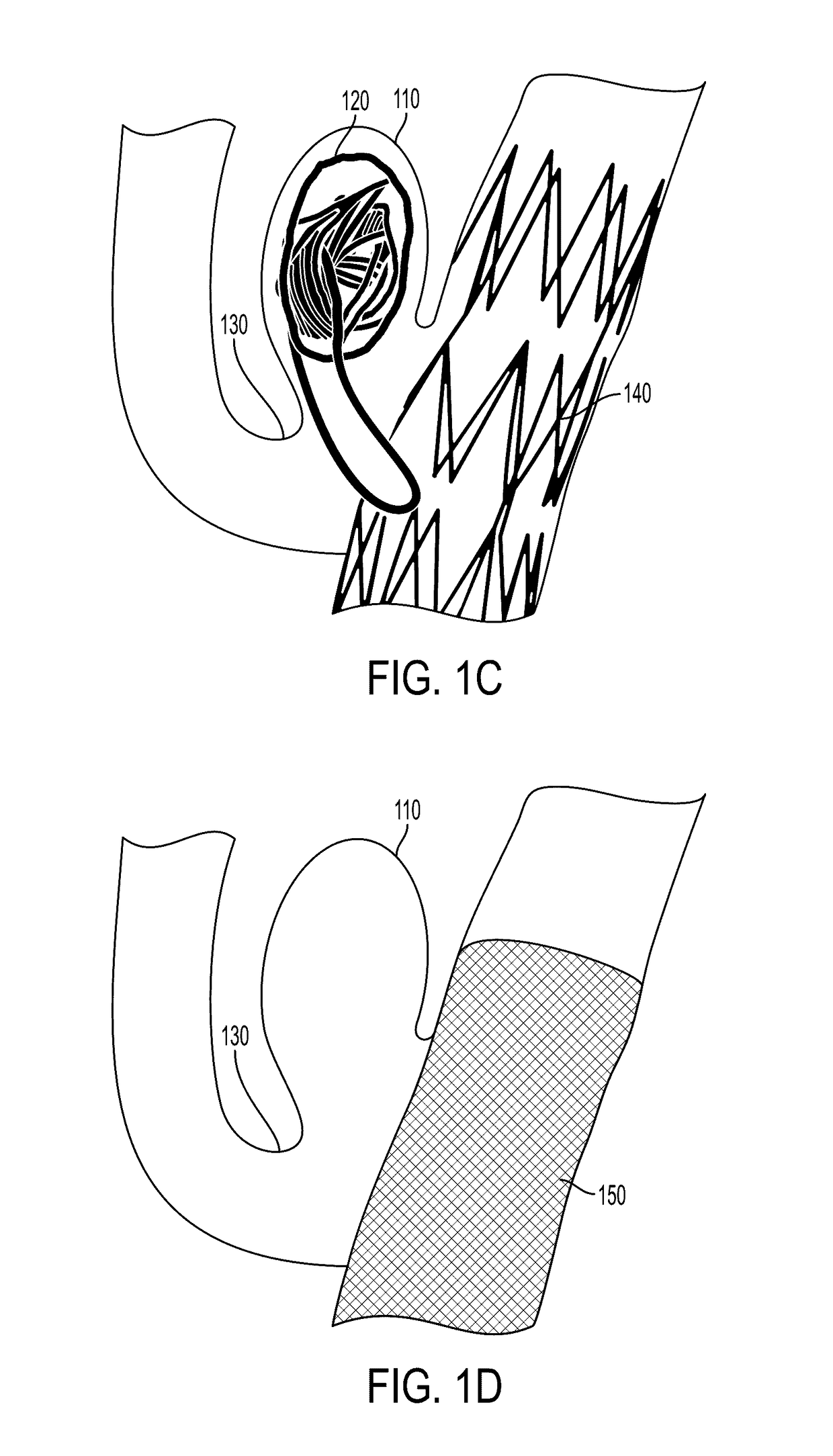

Geometry Based Method for Simulating Fluid Flow Through Heterogeneous Porous Media

ActiveUS20170098019A1Limit accuracyCalculation intensiveStentsVolume measurement apparatus/methodsModel systemHeart disease

A profile of porosities and permeabilities calculated from several sample volumes in a system can speed up computational fluid dynamics (CFDs). Heterogeneous fluid flow paths can be calculation intense, limiting the accuracy of fluid-path models. Further, allowing a user to define a number of sample volumes in a model system allows pre-calculation of porosities and permeabilities for use in Navier-Stokes formulas for modeling fluid flow and gives the user control over calculation time and accuracy. This is helpful, for example, in modeling endovascular interventions where fluid dynamics are determinative in the efficacy or method of treatment for various vascular disorders, such as aneurysms, and heart disease. This is also beneficial in other healthcare contexts, like blood filters, embolic gels, endografts, web devices, and atrial appendage occluders, among others. This disclosure is also relevant to fluid dynamics generally, such as in consumer products; and oil and gas exploration, recovery, and production.

Owner:ARIZONA STATE UNIVERSITY

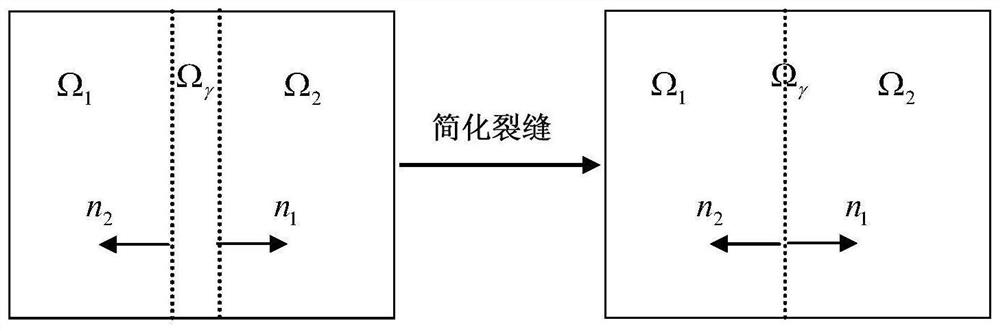

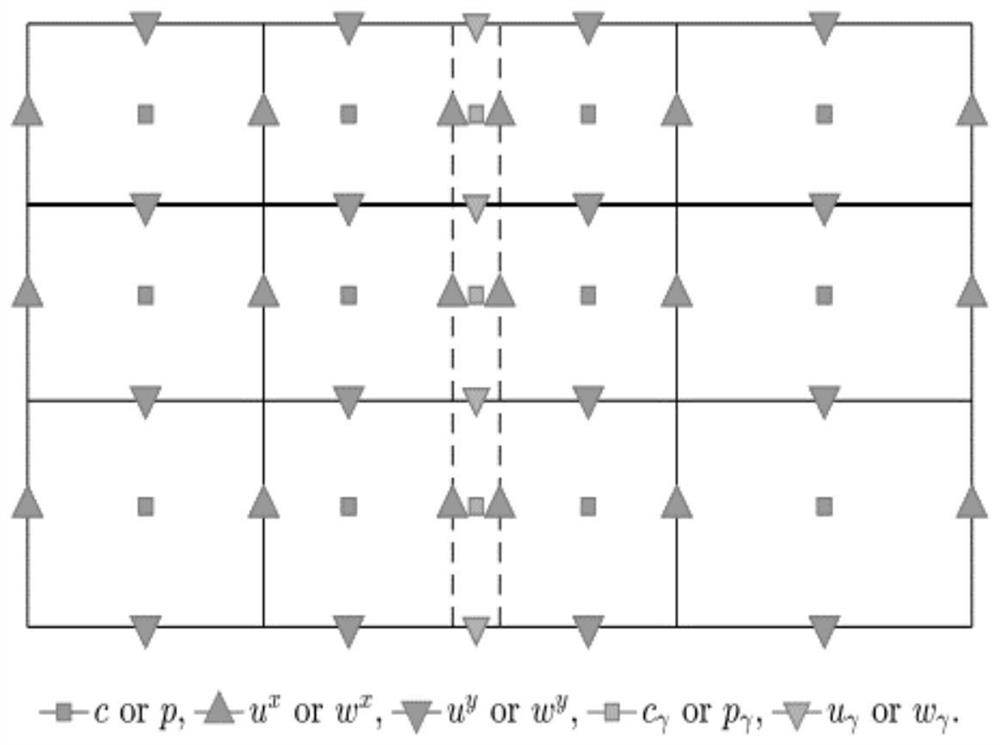

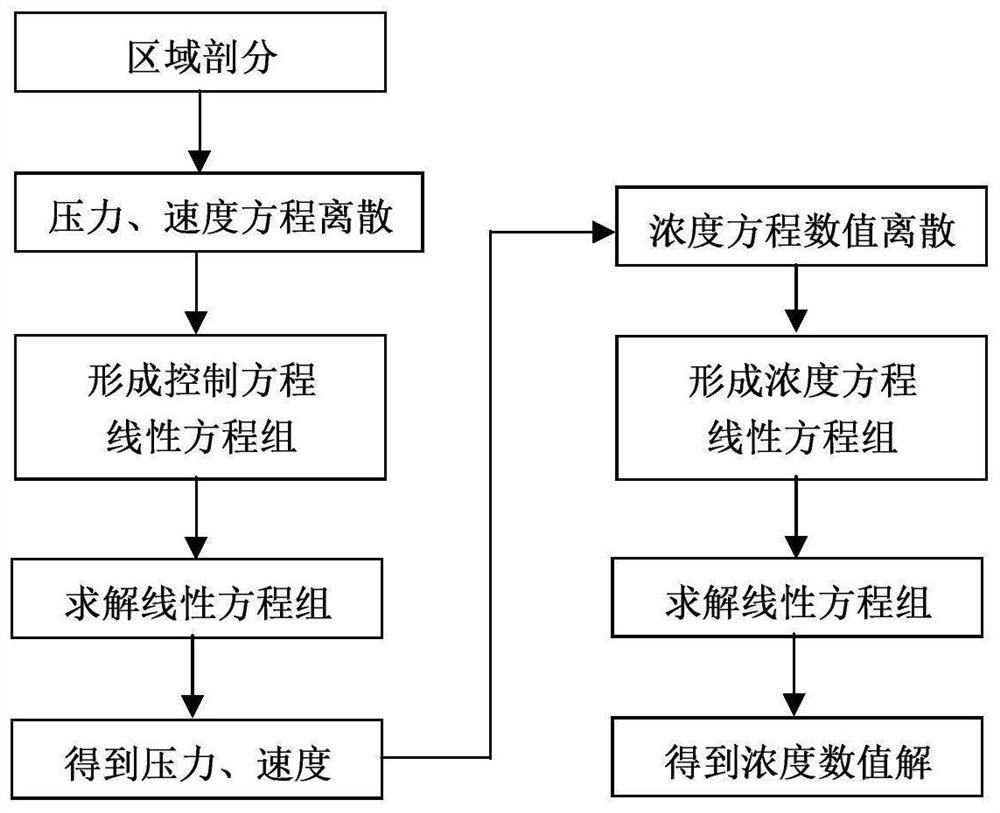

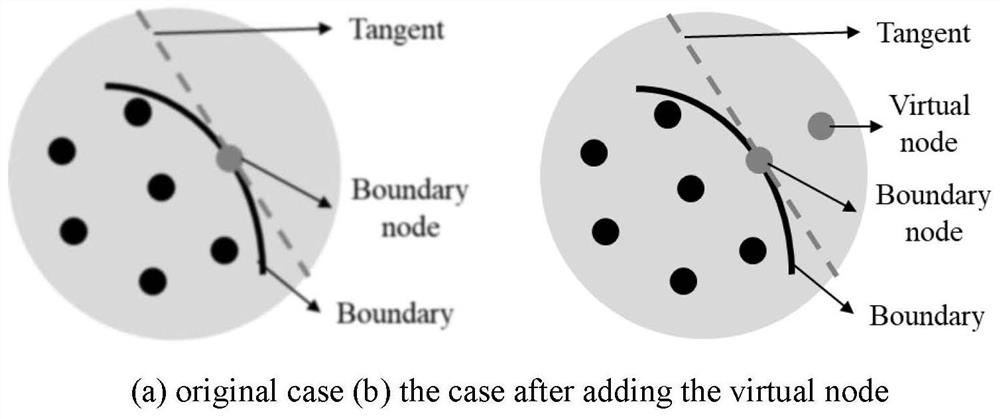

Method and device for achieving underground fluid flow numerical simulation based on fractured porous medium fluid mathematical model and storage medium

ActiveCN113033057AAccurate descriptionMitigate the risk of bad numerical simulationsDesign optimisation/simulationCAD numerical modellingMathematical modelClassical mechanics

Owner:SHANDONG UNIV

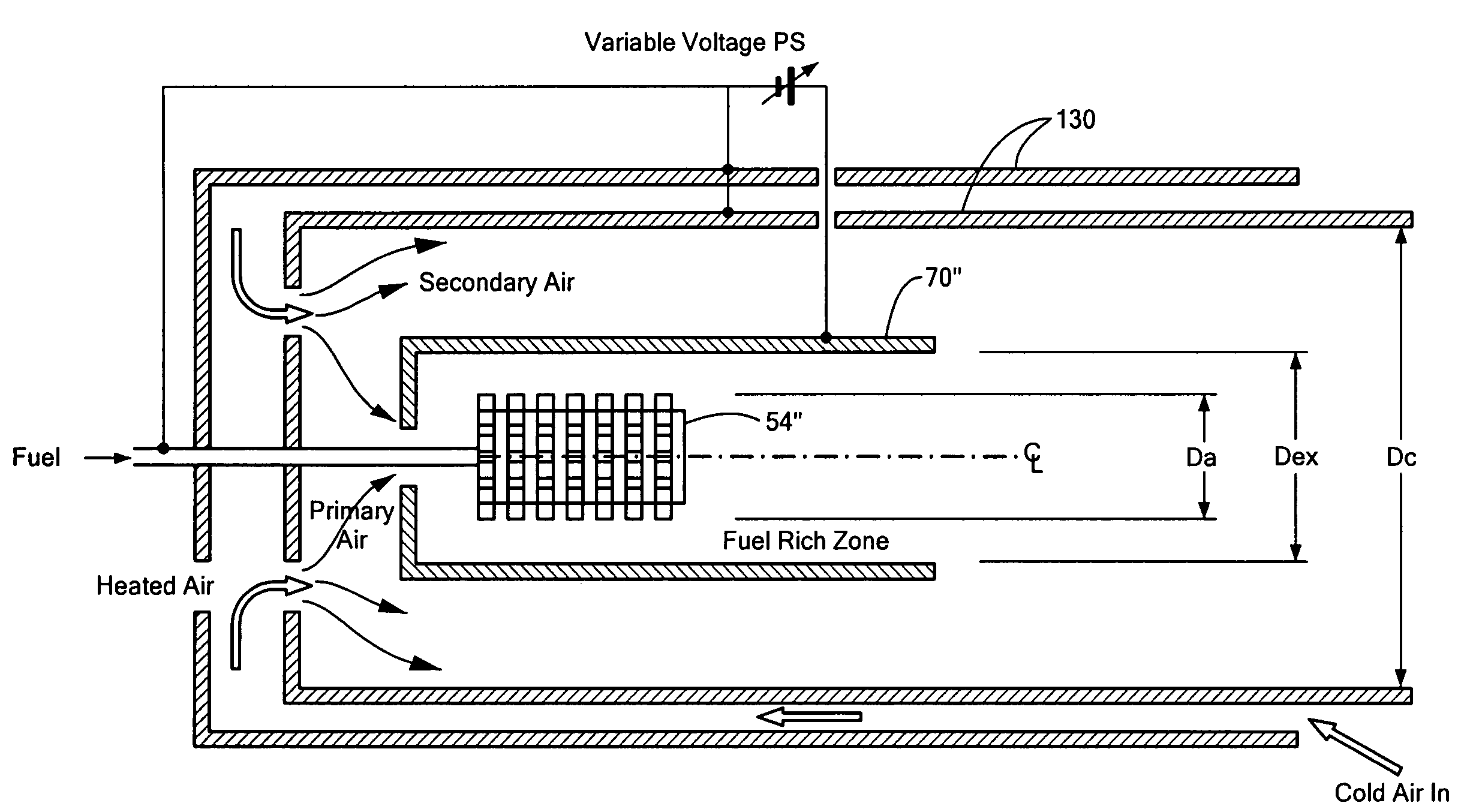

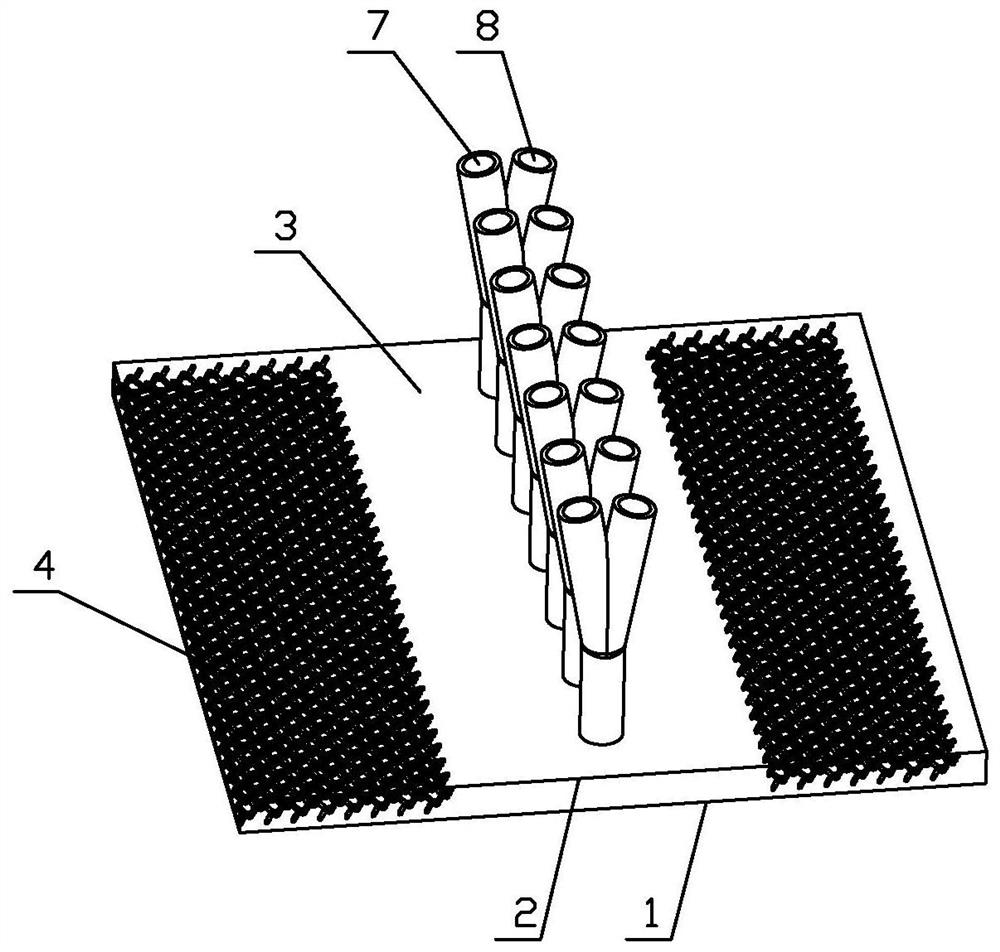

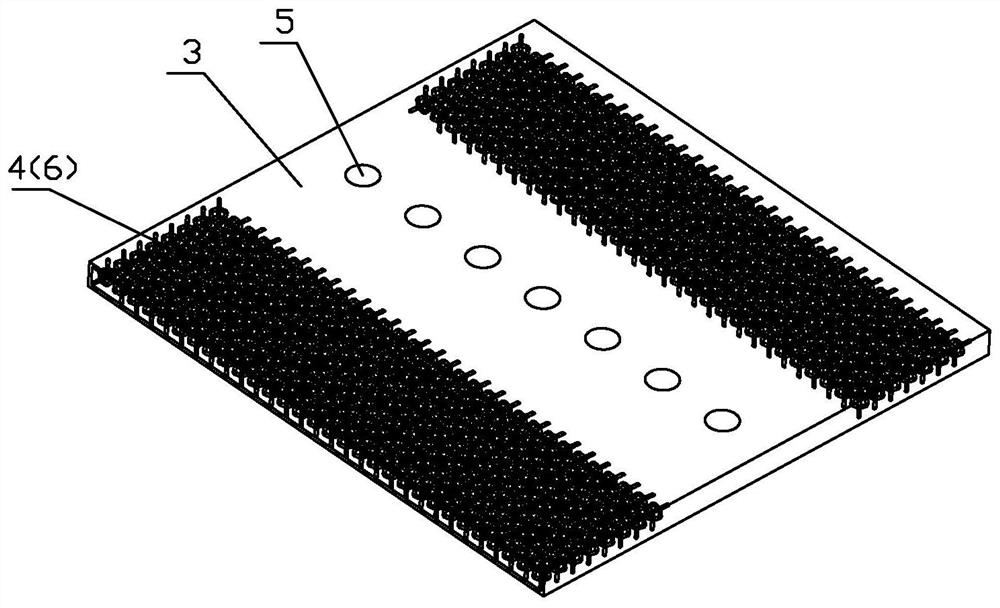

Porous medium turbulent flow jet cooling device

PendingCN112788918AExtended stayIncrease the heat exchange areaCooling/ventilation/heating modificationsCold plateMechanics

The invention provides a porous medium turbulent flow jet flow cooling device which comprises a first cold plate and a second cold plate. The first cold plate is tightly attached to a heating element, a jet flow cavity is formed between the first cold plate and the second cold plate, the second cold plate is provided with jet flow holes, jet flow enters the jet flow cavity through the jet flow holes and impacts the first cold plate. The impacted surface of the first cold plate is a smooth surface; a turbulent flow cavity is further formed between the first cold plate and the second cold plate, the turbulent flow cavity is communicated with the jet flow cavity, and a porous medium is arranged in the turbulent flow cavity. The fluid passes through the jet flow inlet and impacts the inner surface of the first cold plate, the flow path is short, and a flow boundary layer on the impacted surface is thin, so that the area which is directly impacted generates a very strong heat exchange effect. And after the heat exchanger passes through the turbulent flow porous medium, the porous medium destroys a flow boundary layer formed in the flow channel and increases turbulent flow in the flow, so that the heat exchange effect is further enhanced.

Owner:CRRC DALIAN INST CO LTD

Formulation and method of use for exploitation of heavy and extra heavy oil wells

InactiveUS9109443B2High trafficDecrease productivityFluid removalDrilling compositionFuel oilCarrier fluid

A combined injection and production method includes establishing a production well and an injection well into a hydrocarbon-bearing formation; introducing a mixture of a surfactant, a co-surfactant and a carrier fluid into each of the production well and the injection well so that the mixture flows into porous media surrounding the production well and the injection well; holding the mixture in the porous media surrounding the production well in the presence of water for a period of time sufficient to form a water film on surfaces of the porous media surrounding the production well; and injecting an injection fluid into the injection well while producing from the production well, whereby hydrocarbons flow from the porous media around the injection well toward the production well.

Owner:INTREVEP SA

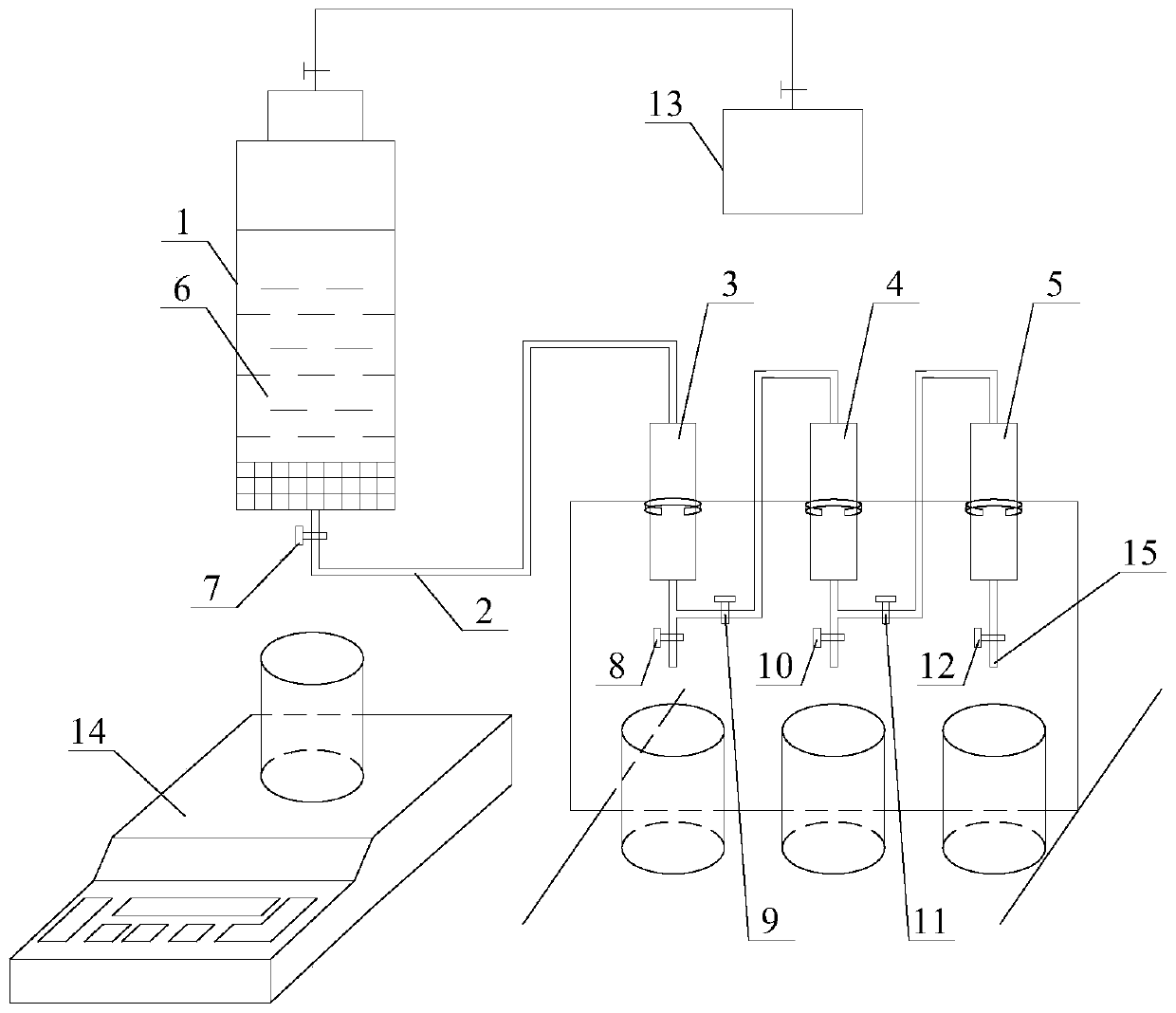

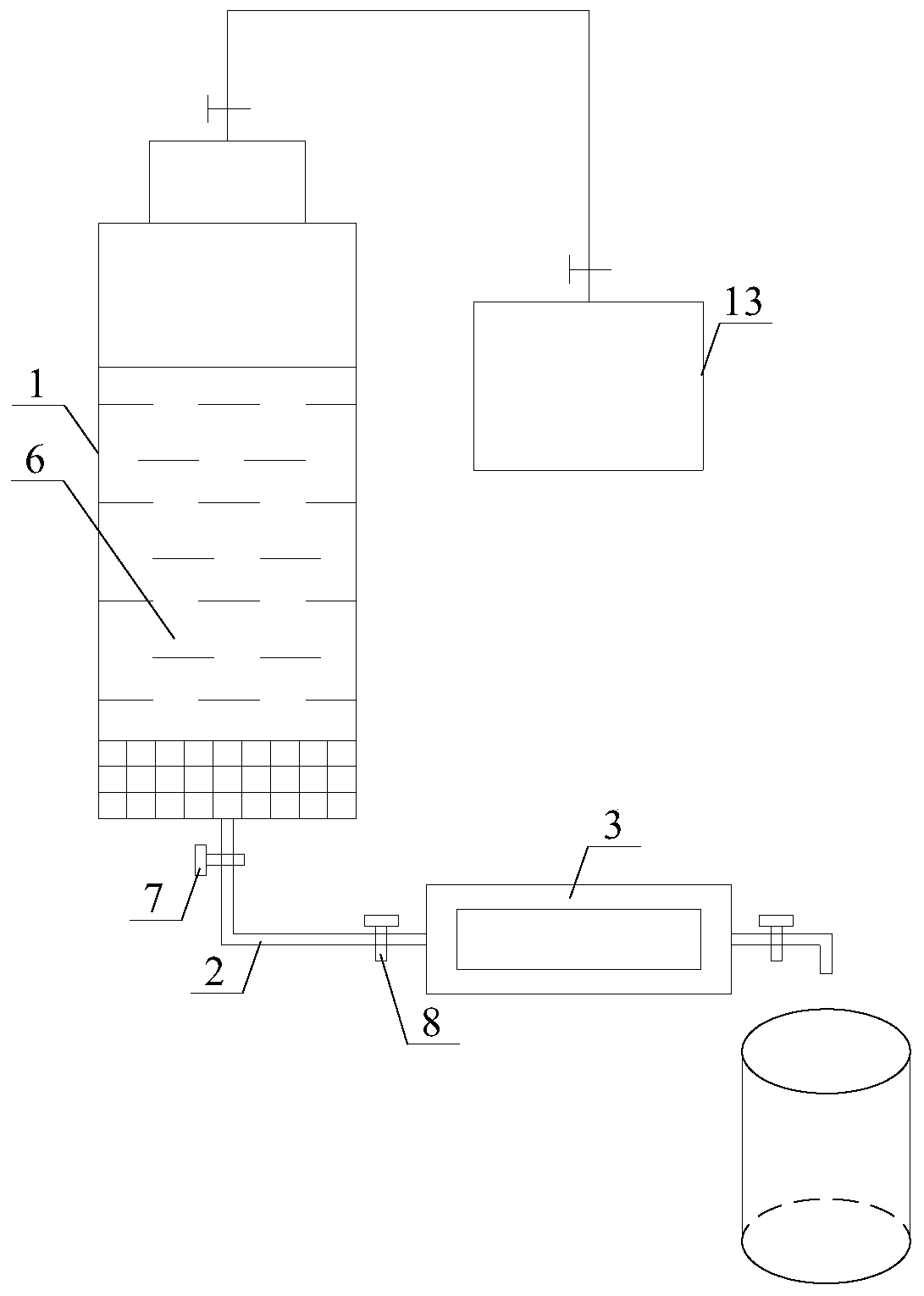

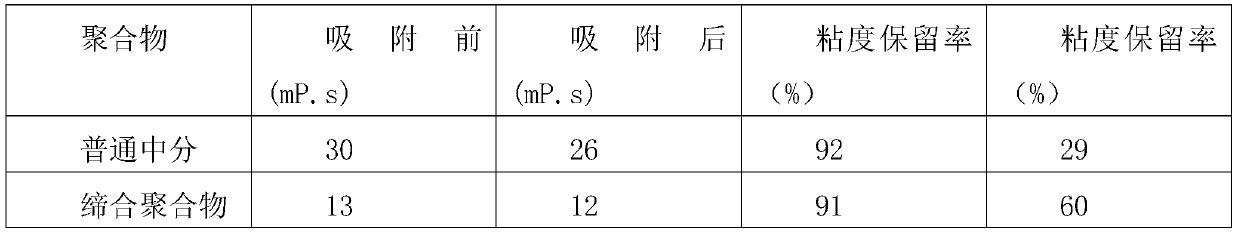

Method and device for evaluating adsorbability of polymer solution in porous medium

The invention discloses a method and a device for evaluating the adsorbability of a polymer solution in a porous medium. The method comprises the following steps of loading a polymer solution with known performance parameters into a filtration factor device capable of presetting driving pressure, sequentially driving the polymer solution into multiple sequentially serially connected porous mediummodels through the filtration factor device, then using a detecting instrument for detecting performance parameters of the polymer solution flowing through the various porous medium models, and meanwhile, detecting the changes of the performance parameters of the polymer solution before and after the driving process. The method and the device for evaluating the adsorbability of the polymer solution in the porous medium provided by the invention are suitable for screening samples in multiple quantity, and are capable of simply, conveniently, quickly and effectively evaluating the influence on performances of the solution due to the flowing of porous media, and beneficial to comparing multiple sample performance advantages and disadvantages; the detection through multiple methods can be realized; and the device is simple in structure and convenient to operate.

Owner:王雷 +2

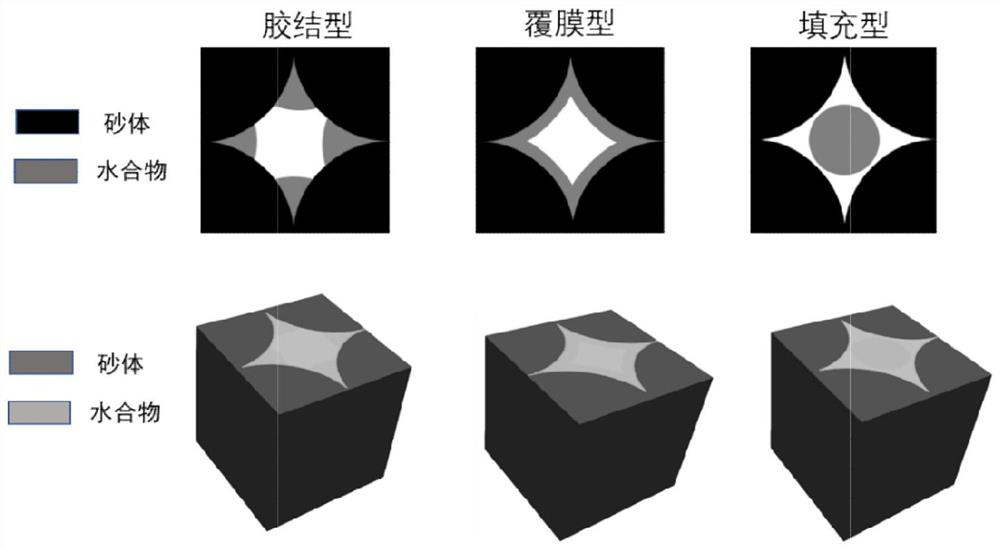

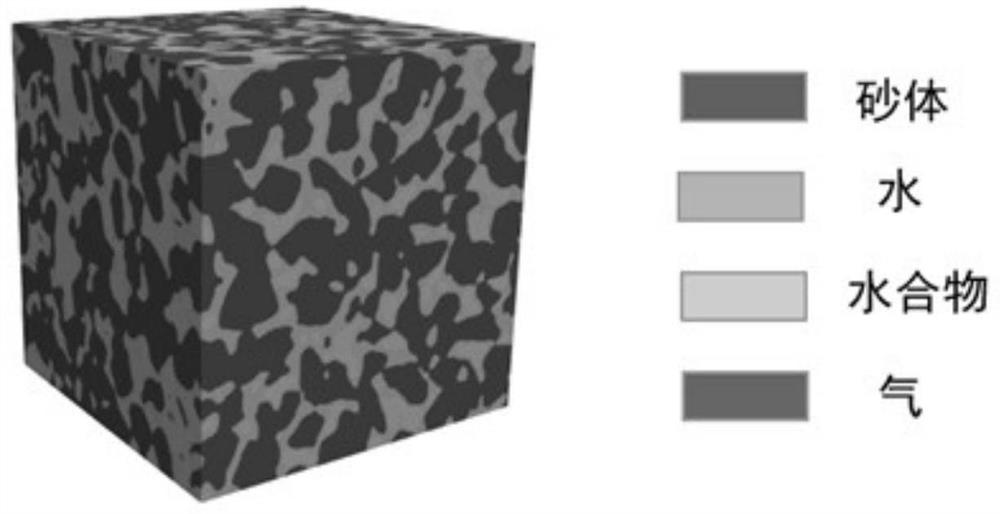

Hydrate occurrence form division method based on pore network model

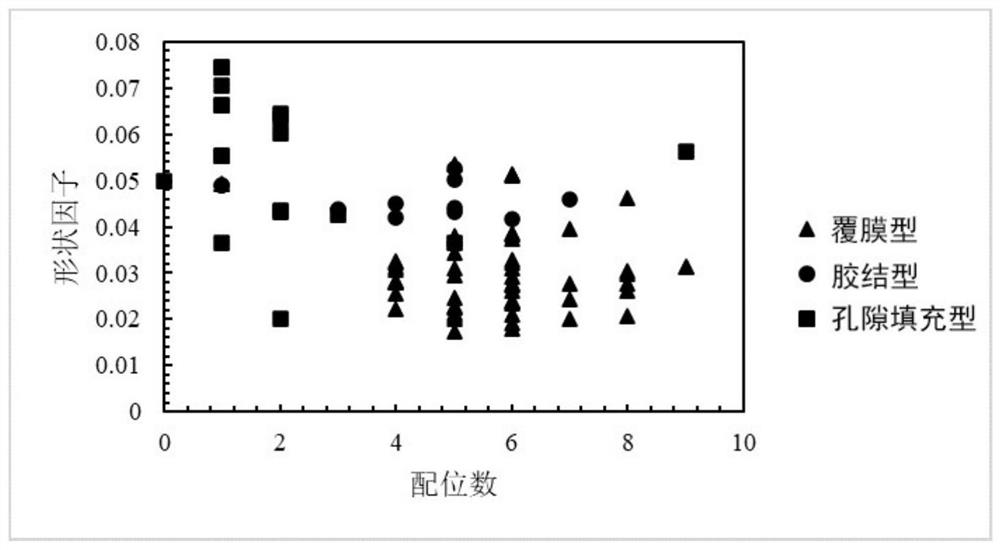

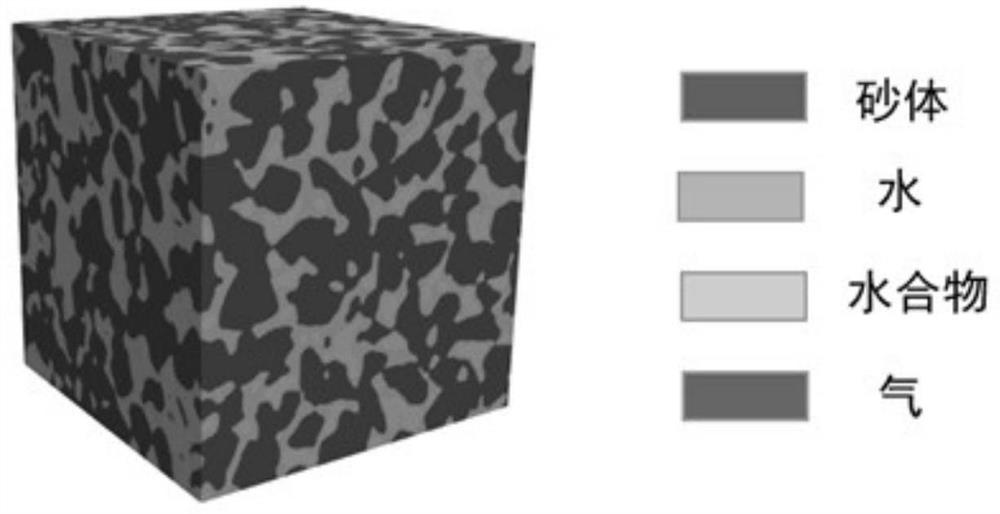

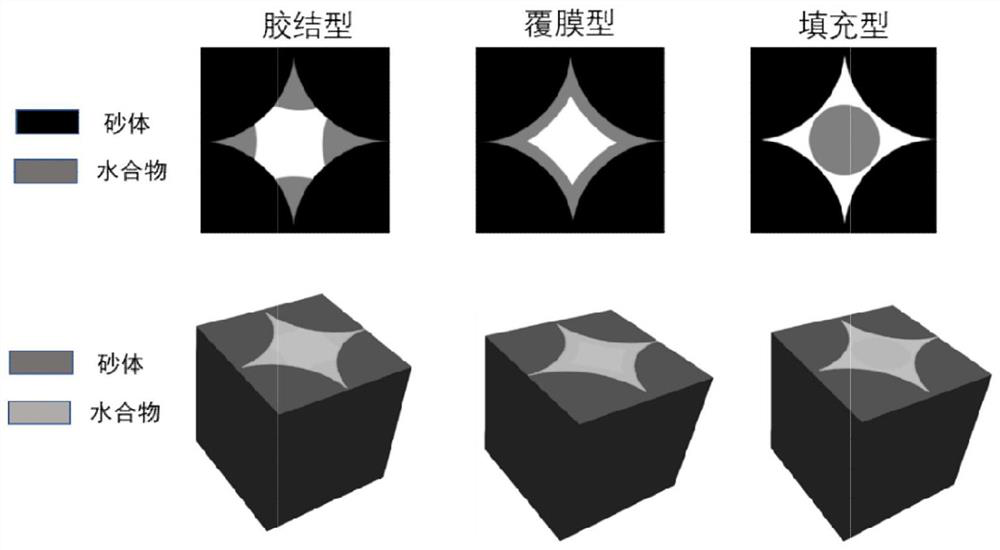

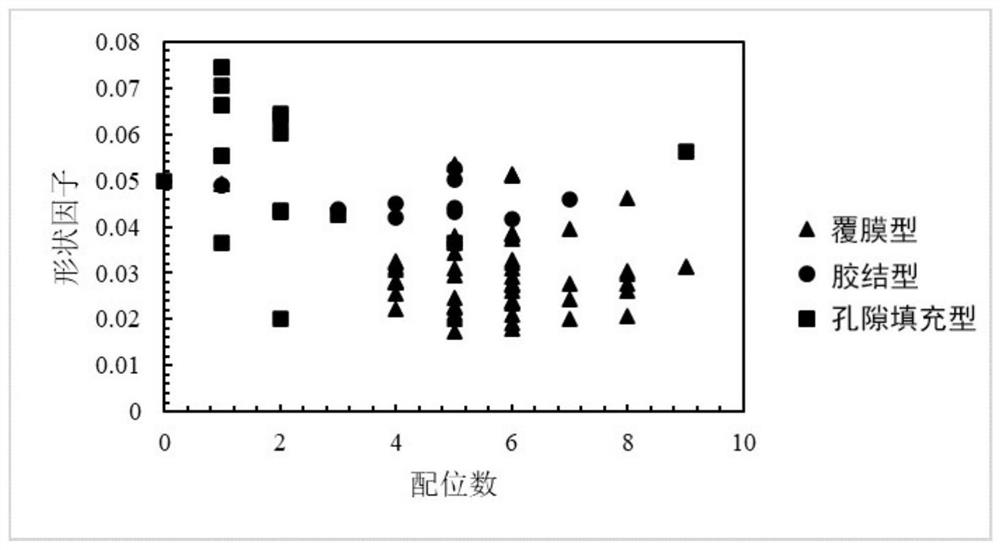

ActiveCN112151125AAccurate divisionConvenient researchChemical property predictionRock coreNetwork model

The invention relates to the field of hydrate form division, in particular to a hydrate occurrence form division method based on a pore network model. According to the method, hydrate shape factors ofthree hydrate occurrence forms and coordination numbers are counted, a hydrate occurrence form division standard is made, a hydrate-containing rock core needing to be divided is subjected to CT scanning, then a hydrate-containing digital rock core is established, and after the relation between the hydrate and rock core pores is judged, Shape factors and coordination numbers of the corresponding hydrates are extracted from the digital rock cores containing the hydrates and are compared by using a hydrate occurrence form division standard, so that the occurrence form of the hydrates is determined. According to the method, the division standard of the hydrate is specifically in a numerical value form, compared with an existing method, judgment and division of the occurrence form of the hydrate are more accurate and specific, and subsequent research on the influence of the hydrate on the flow characteristics of the porous medium is facilitated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A Method for Classifying Hydrate Occurrence Forms Based on Pore Network Model

The invention relates to the field of hydrate form division, in particular to a hydrate occurrence form division method based on a pore network model. In the present invention, the hydrate occurrence form classification standard is made by counting the hydrate shape factors and coordination numbers of the three occurrence forms of hydrate, and the hydrate-containing cores that need to be divided are scanned by CT to establish the hydrate-containing classification standard. Digital cores, after judging the relationship between hydrates and core pores, extract the shape factors and coordination numbers of the corresponding hydrates from the digital cores containing hydrates and compare them with the hydrate occurrence form classification standard to determine the occurrence of hydrates. form. In the present invention, the classification standard of hydrate is specified in the form of numerical value. Compared with the existing method, the judgment and classification of the occurrence form of hydrate is more accurate and specific, which facilitates the subsequent research on the influence of hydrate on the flow characteristics of porous media. .

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

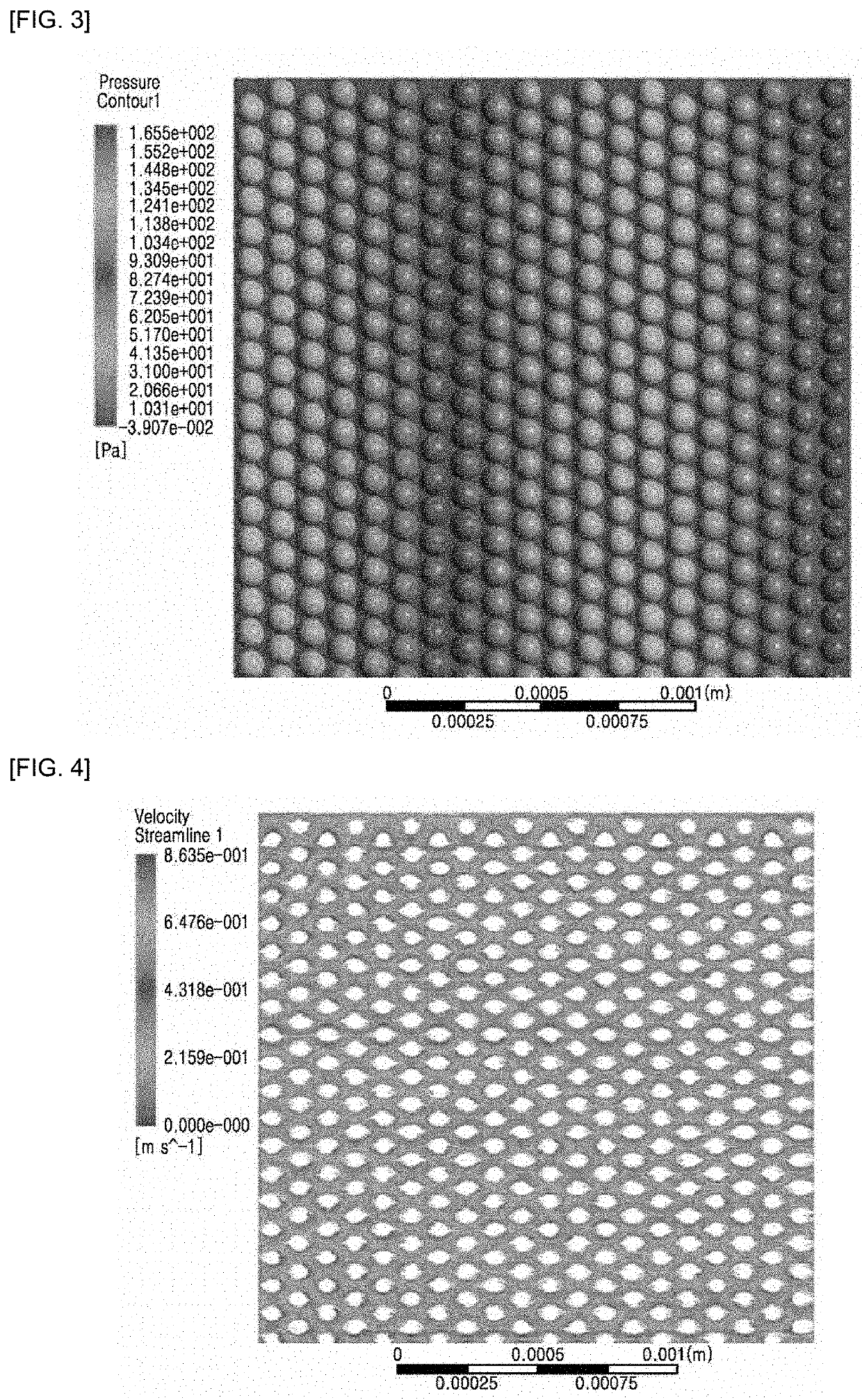

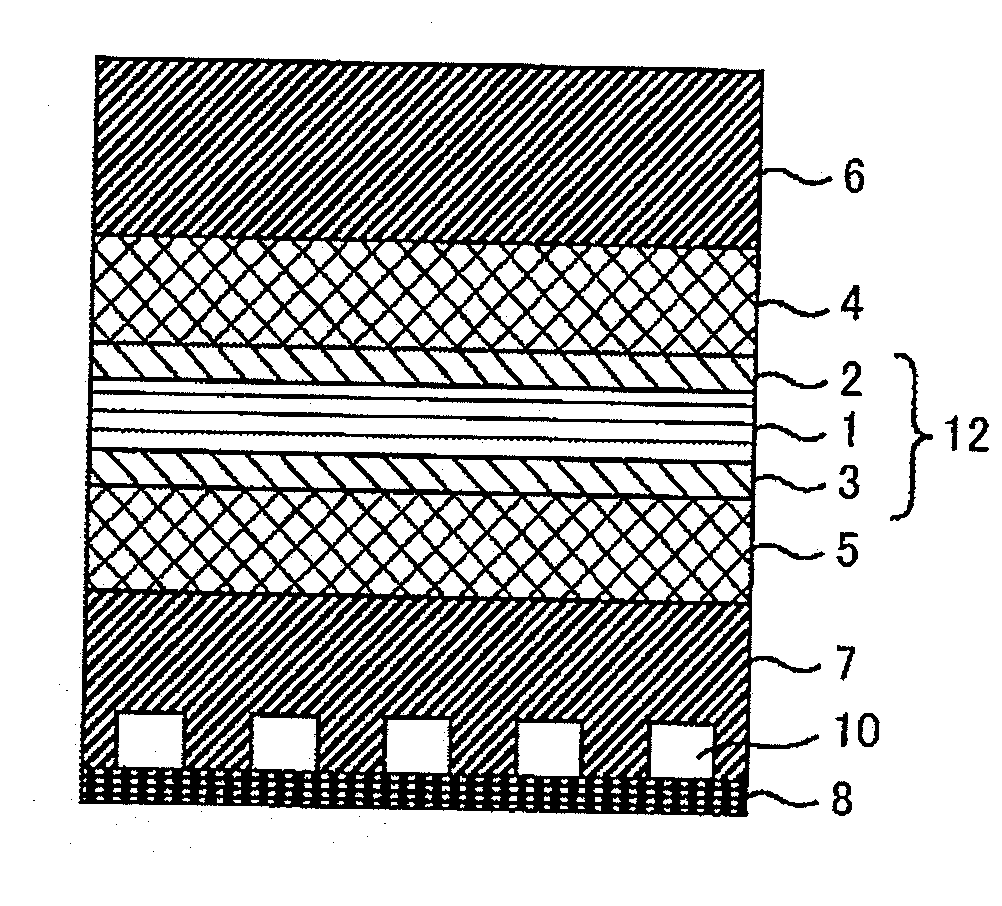

A Spherical Fuel Element Simulator for Measuring Wall Temperature and Its Assembly Process

ActiveCN102881339BEasy to measureAccurate measurementFuel elementsNuclear energy generationEngineeringSoldering

The invention discloses a spherical fuel element simulator being convenient for wall temperature measurement and assembly technology for the spherical fuel element simulator being convenient for the wall temperature measurement. The spherical fuel element simulator provided by the invention comprises a rodlike electrical heating element; two ends of the electrical heating element are respectively connected with an upper current-conducting plate and a lower current-conducting plate; an internally-concaved blind hole is arranged at one end of the electrical heating element; a round hole communicated with the bottom of the blind hole is arranged on the side wall of the electric heating element; a sheathed thermocouple is installed in the blind hole; an insulating bush is arranged between the sheathed thermocouple and the electric heating element; and the round hole is filled and soldered with silver soldering. With the adoption of the spherical fuel element simulator provided by the invention, the sheathed thermocouple in each electric heating element can be installed, and any depth in any electric heating element can be measured; and the spherical fuel element stimulator is applicable to an irrigation work feature test; geometry size and arrangement size of the electrical heating element are figured out by taking the spherical fuel element stimulator as a standard and according to porous media fluid dynamics and heat transfer theory; and with the adoption of the spherical fuel element simulator, thermotechnical irrigation work features of the spherical fuel element can be effectively stimulated.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Formulation and method of use for exploitation of heavy and extra heavy oil wells

InactiveUS20120247759A1Improve well productivityHigh trafficFluid removalDrilling compositionFuel oilCarrier fluid

A combined injection and production method includes the steps of: establishing a production well and an injection well into a hydrocarbon-bearing formation; introducing a mixture of a surfactant, a co-surfactant and a carrier fluid into each of the production well and the injection well so that the mixture flows into porous media surrounding the production well and the injection well; holding the mixture in the porous media surrounding the production well in the presence of water for a period of time sufficient to form a water film on surfaces of the porous media surrounding the production well; and injecting an injection fluid into the injection well while producing from the production well, whereby hydrocarbons flow from the porous media around the injection well toward the production well.

Owner:INTREVEP SA

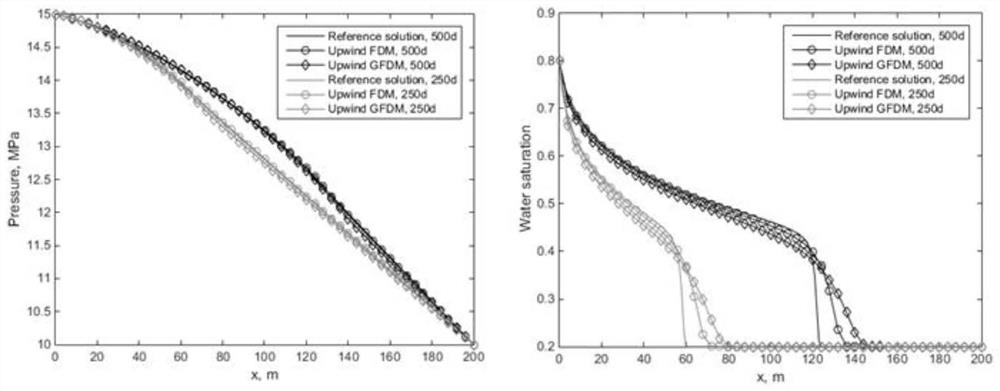

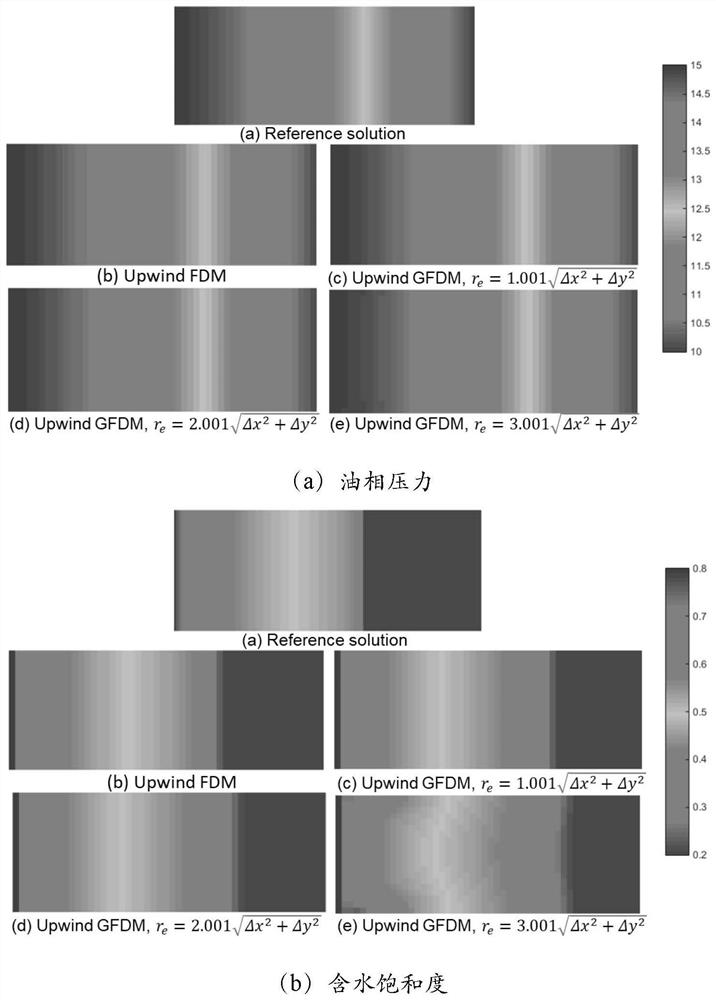

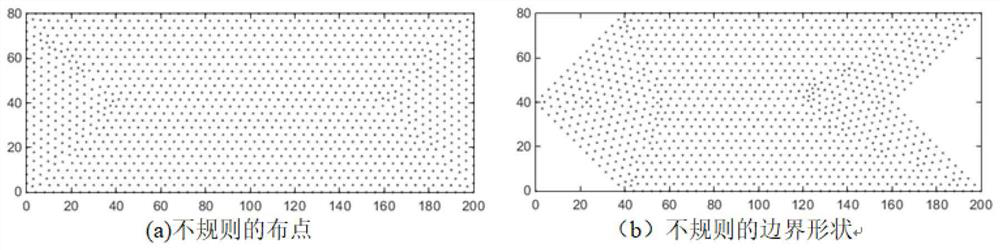

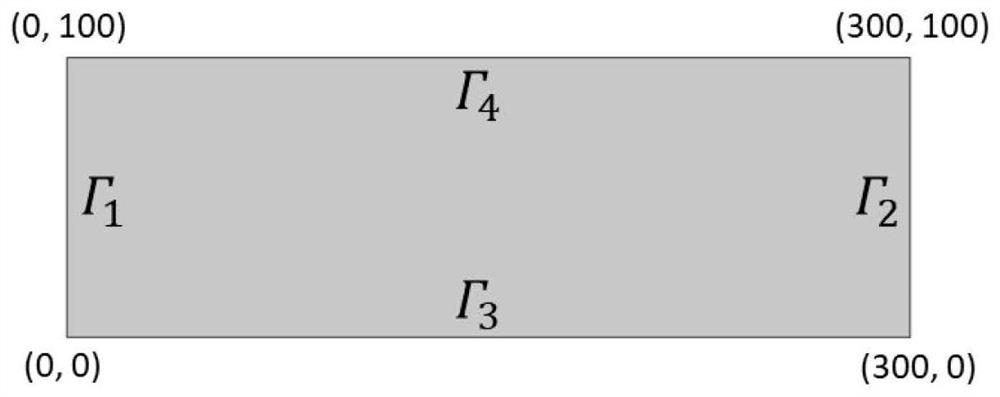

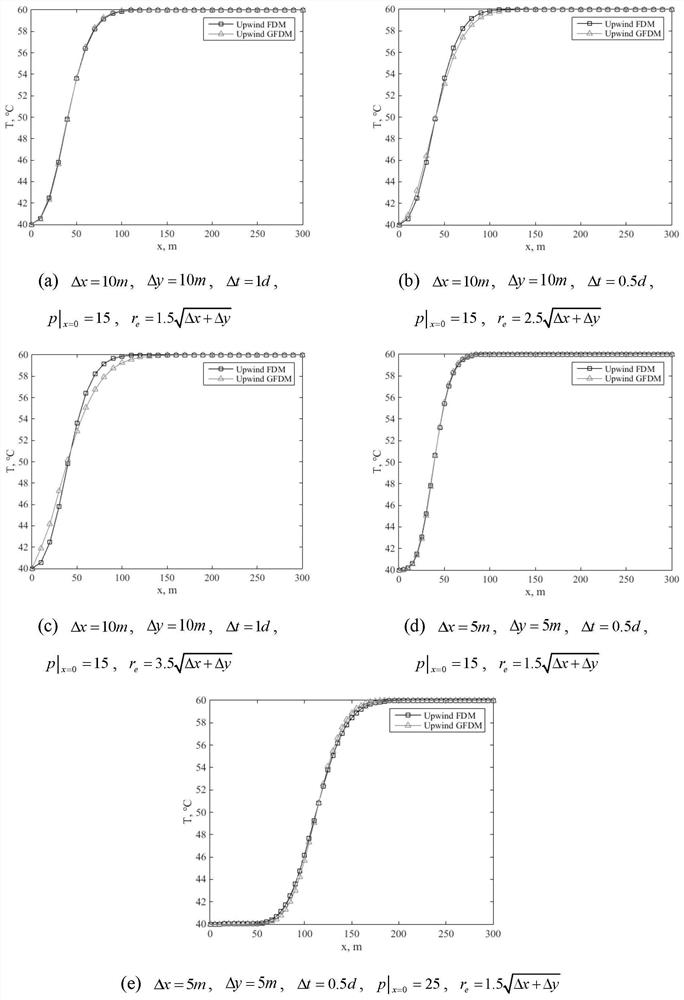

Method for calculating porous medium oil-water two-phase flow based on windward GFDM

Owner:YANGTZE UNIVERSITY

Test system and method of fluid non-linear percolation characteristics in low-permeability porous media

ActiveCN102297830BEasy to measureLittle changePermeability/surface area analysisEngineeringDisplacement pressure

The invention provides a test system and method of fluid non-linear percolation characteristics in a low-permeability porous media. The test system comprises a plurality of test branches, wherein, each test branch comprises a displacement pressure output unit for providing different pressures to transfer displacing fluid to a test core, a pressure measuring unit for the pressure of the displacingfluid output by the displacement pressure output unit, a flowing unit for accommodating the test core and providing ring crush to the test core, a flow measuring unit for measuring the flow of the displacing fluid flowing through the test core, and a thermostatically control unit for providing a constant ambient temperature for the flowing unit and the flow measuring unit. By adopting the thermostatically control unit, the influence of variation in temperature to the test results is eliminated, so that the test results are accurate.

Owner:PETROCHINA CO LTD

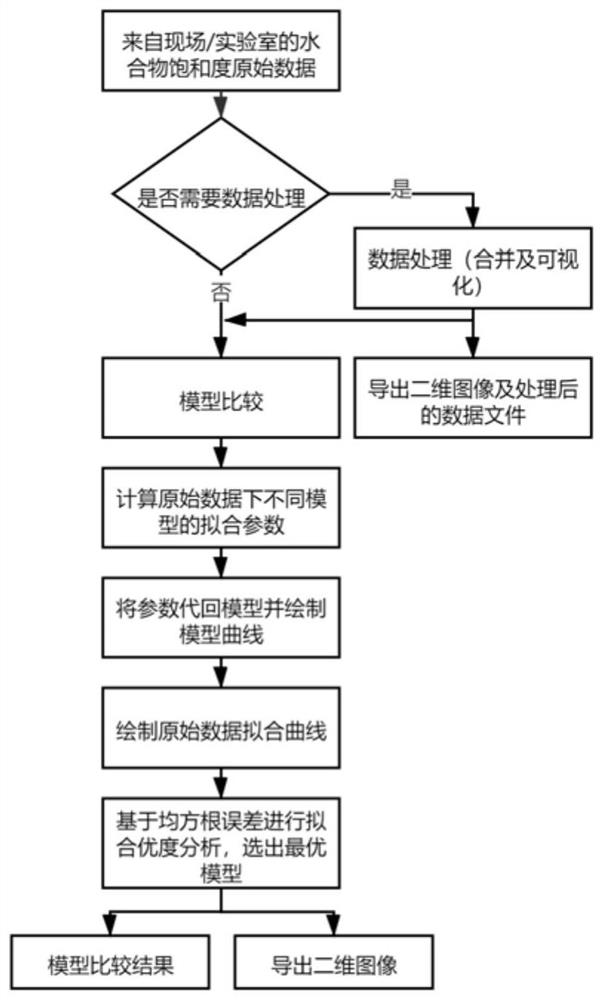

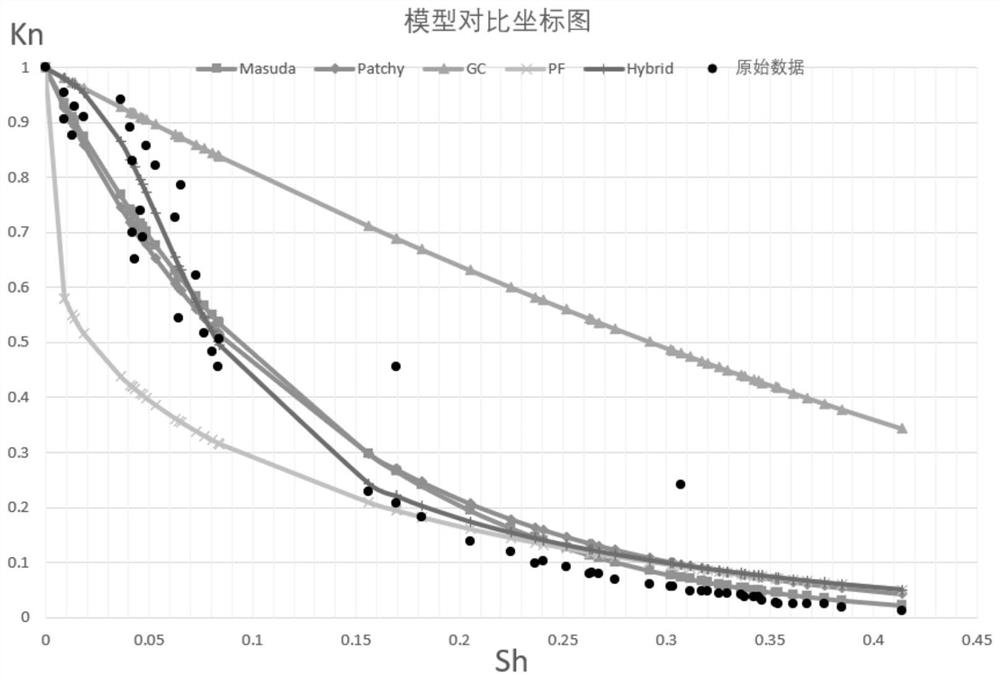

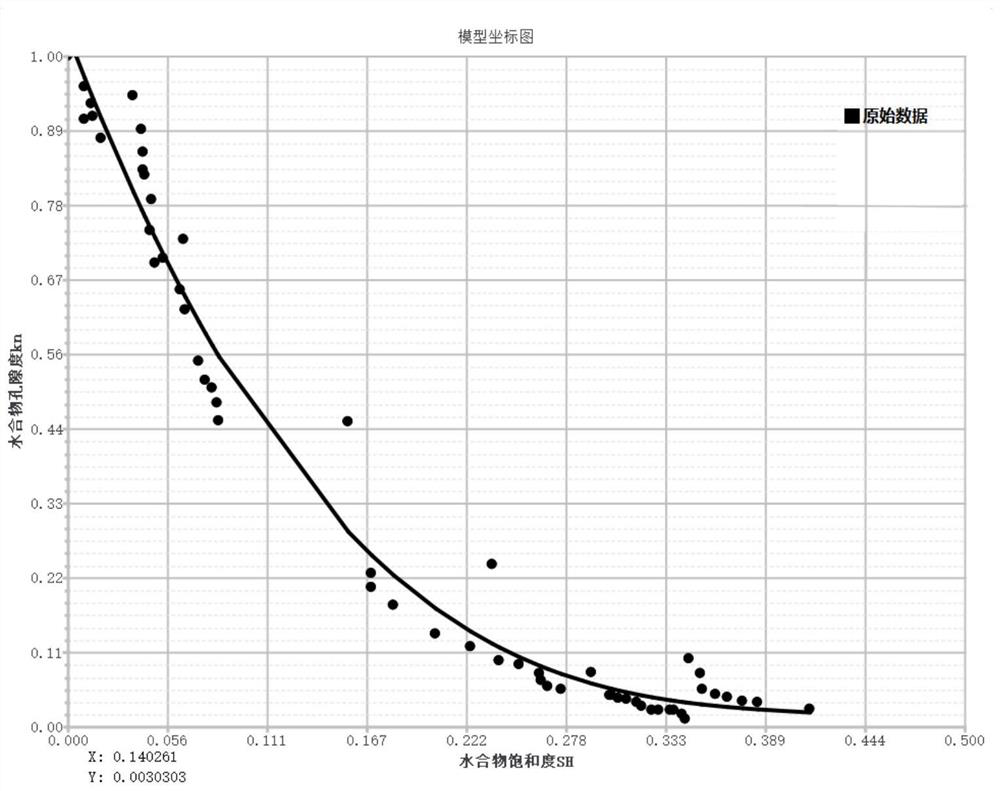

Real-time visualization method for hydrate permeability correlation analysis and model prediction

PendingCN113836747AFast visualizationReduce computing workDrawing from basic elementsVisual data miningOptimality modelOriginal data

The invention discloses a real-time visualization method for hydrate permeability correlation analysis and model prediction, and belongs to the field of energy and the related fields of underground fluid flow and porous medium flow. The method has two main functions of original data processing and model comparative analysis. The method can meet various scientific research requirements of hydrate detection and collection sites, laboratories and the like. According to the method, optimal fitting calculation of a hydrate sediment permeability model is completed based on hydrate original saturation and permeability data imported from the outside, a visual permeability model fitting curve, a permeability fitting result and a root-mean-square error calculation result are obtained, and an optimal model is optimized according to the error result. The combination and display of multiple groups of original data are supported. According to the method, quick visualization processing can be carried out on shipborne field data and laboratory measurement data, calculation of optimal model fitting parameters and screening of optimal models are supported, and the method has the advantages of being simple and easy to use, high in automation degree, low in software and hardware dependency and the like.

Owner:DALIAN UNIV OF TECH

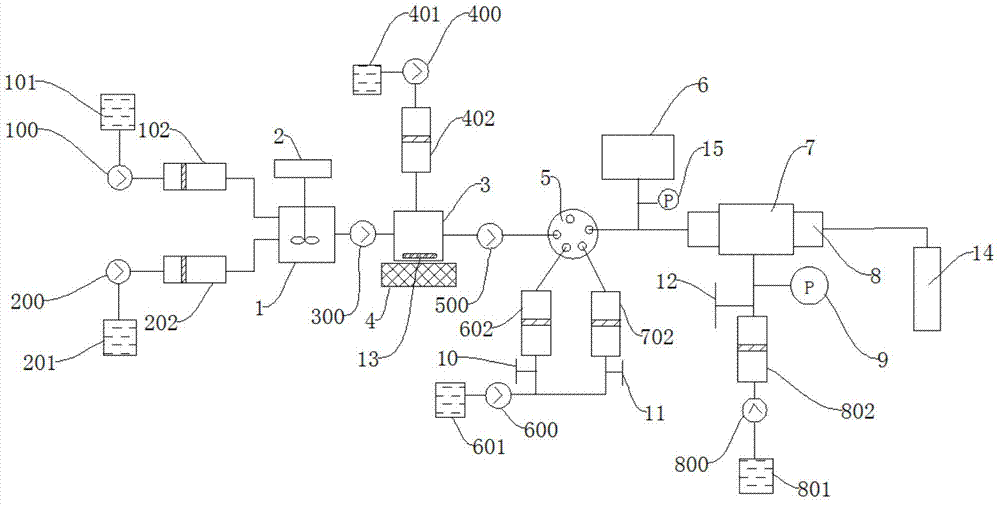

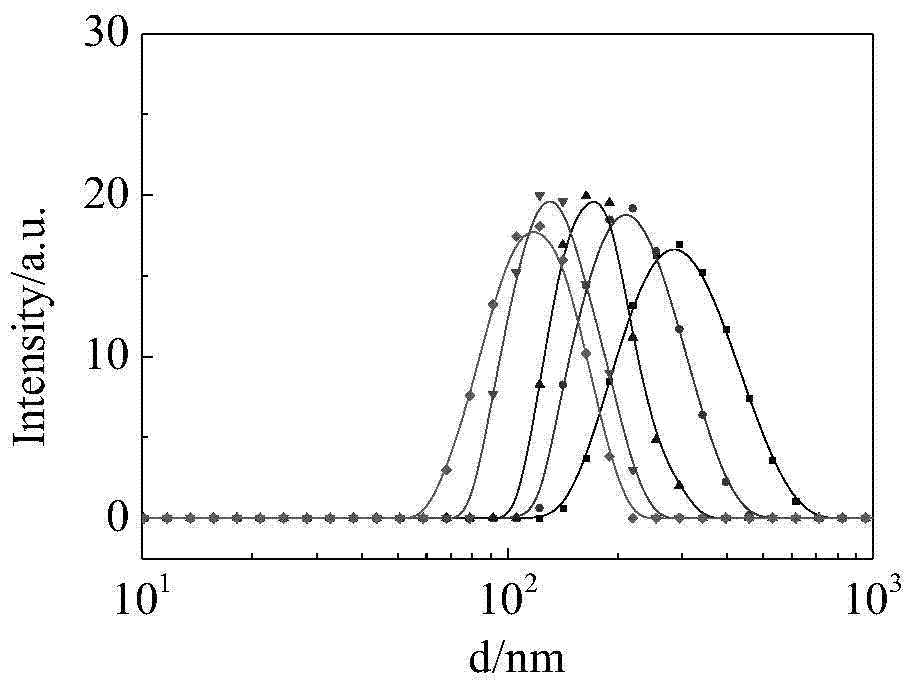

A porous medium flow measurement device and measurement method for nanoemulsion

InactiveCN105203431BReduce particle size changeAvoid interferenceFlow propertiesPreparing sample for investigationMeasurement deviceEngineering

The invention discloses a porous medium flow measurement device for nanoemulsions, which includes a sample preparation system, a sample introduction system and a measurement system; the sample preparation system includes a first sampling pump, a first water storage, a second sampling pump, a Two water reservoirs, the first intermediate container, the second intermediate container, the first mixing chamber, the second mixing chamber, the third sampling pump, the fourth sampling pump, the fourth water storage, the fourth intermediate container, and a mechanical mixer , electromagnetic heating stirrer and magnet; the sampling system includes the sixth sampling pump, the sixth water storage, the sixth intermediate container, the seventh intermediate container, valve one, valve two, fifth sampling pump and multi-way valve The measurement system includes a core holder, a core, a pressure acquisition system, a pressure gauge, an eighth sampling pump, an eighth water storage, a pressure gauge two, a valve three and a metering container. The present invention also provides a measurement method for the porous medium flow of the nanoemulsion by using the above-mentioned device. The invention improves the reproducibility, accuracy and usability of flow experiment data.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Reservoir porous medium flow temperature coupling model calculation method based on windward GFDM

ActiveCN114048651ADesign optimisation/simulationSpecial data processing applicationsDiscretizationMechanics

The invention discloses a reservoir porous medium flow temperature coupling model calculation method based on windward GFDM. The method comprises the following steps: S1, establishing a porous medium flow temperature coupling model of a reservoir; and S2, discretizing the porous medium flow temperature coupling model based on windward GFDM to obtain a discretization format of the porous medium flow temperature coupling model, and constructing a GFDM windward format for treating a heat convection term without transforming an influence domain. The invention provides the reservoir porous medium flow temperature coupling model calculation method based on windward GFDM. GFDM is applied to numerical modeling of a flow temperature coupling problem.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com