Preparation method of egg yolk‑eggshell structure nitrogen-doped carbon-coated ferric oxide@tin dioxide magnetic nanobox

A technology of carbon-coated ferroferric oxide and magnetic nanometers, which is applied in nanotechnology, nanotechnology, structural parts, etc., can solve problems such as poor rate characteristics and cycle performance, limited commercial applications, and large volume effects, and achieves Good shape control, excellent cycle stability, and the effect of mitigating volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

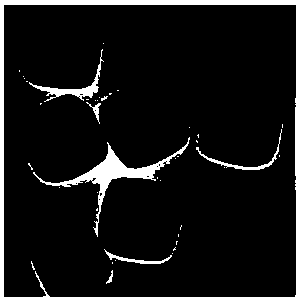

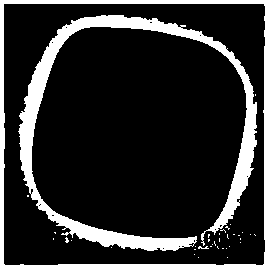

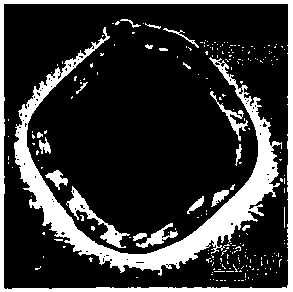

Image

Examples

Embodiment 1

[0027] 1. Preparation of Fe2O3 nanocubes:

[0028] Dissolve 80mg of ferric chloride hexahydrate and 40mg of solid sodium hydroxide in 90mL of deionized water, mix well at 25°C and transfer to a 150 mL polytetrafluoroethylene-lined hydrothermal reactor at 100°C Reaction 24h. After the reaction was over, the reaction kettle was taken out, the red product was centrifuged and washed three times with deionized water and absolute ethanol, and finally dried in a vacuum oven for 12 h. The resulting product is ferric oxide nanocubes.

[0029] 2. Preparation of core-shell structure ferric oxide@silica nanocubes:

[0030] Ultrasonic disperse 100 mg of the above-mentioned iron sesquioxide nano-cubic in 70 mL of absolute ethanol. After the dispersion is uniform, add 6.5 mL of deionized water, 15 mg of ammonia water and 30 mg of tetraethyl orthosilicate (TEOS), in a water bath at 30 °C Under the reaction 2h. After the reaction, the product was centrifuged and washed three times with dei...

Embodiment 2

[0036] 1. Preparation of Fe2O3 nanocubes:

[0037] Dissolve 80mg of ferric chloride hexahydrate and 80mg of solid sodium hydroxide in 90mL of deionized water, mix well at 25°C and transfer to a 150 mL polytetrafluoroethylene-lined hydrothermal reactor at 150°C React for 36 h. After the reaction was over, the reaction kettle was taken out, the red product was centrifuged and washed three times with deionized water and absolute ethanol, and finally dried in a vacuum oven for 12 h. The resulting product is ferric oxide nanocubes.

[0038] 2. Preparation of core-shell structure ferric oxide@silica nanocubes:

[0039] Ultrasonic disperse 100 mg of the above ferric oxide nanocubes in 70 mL of absolute ethanol, and after the dispersion is uniform, add 6.5 mL of deionized water, 18 mg of ammonia water and 50 mg of tetraethyl orthosilicate (TEOS), in a water bath at 50 °C Under the reaction 6h. After the reaction, the product was centrifuged and washed three times with deionized wate...

Embodiment 3

[0045] 1. Preparation of Fe2O3 nanocubes:

[0046] Dissolve 80mg of ferric chloride hexahydrate and 160mg of solid sodium hydroxide in 90mL of deionized water, mix well at 25°C and transfer to a 150 mL polytetrafluoroethylene-lined hydrothermal reaction kettle at 180°C Reaction 48h. After the reaction was over, the reaction kettle was taken out, the red product was centrifuged and washed three times with deionized water and absolute ethanol, and finally dried in a vacuum oven for 12 h. The resulting product is ferric oxide nanocubes.

[0047] 2. Preparation of core-shell structure ferric oxide@silica nanocubes:

[0048] Ultrasonic disperse 100 mg of the above-mentioned ferric oxide nanocubes in 70 mL of absolute ethanol, and after the dispersion is uniform, add 6.5 mL of deionized water, 80 mg of ammonia water and 200 mg of tetraethyl orthosilicate (TEOS), in a water bath at 80 °C Under reaction for 12 h. After the reaction, the product was centrifuged and washed three tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com