Single-phase samarium titanate nano-powder prepared by using solution method, and method for preparing single-phase samarium titanate nano-powder

A nano-powder, samarium titanate technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve samarium nitrate and tetrabutyl titanate in 10 ml of acetic acid at a molar ratio of 1:1.2, and stir magnetically in a water bath to form a transparent solution; adjust the temperature of the water bath to 10°C, and slowly add ammonia water to the transparent In the solution, produce milky white product in the solution, continue to add ammoniacal liquor until the pH value of whole system is neutral, completes reaction. Subsequently, the reacted solution was subjected to solid-liquid separation with a centrifuge at a centrifugation rate of 8000 rpm to obtain a white powder. The white powder was dried at 80°C for 2 hours, then transferred to a muffle furnace, and calcined at 800°C for 1 hour to obtain a light yellow Sm 2 Ti 2 o 7 Nano powder.

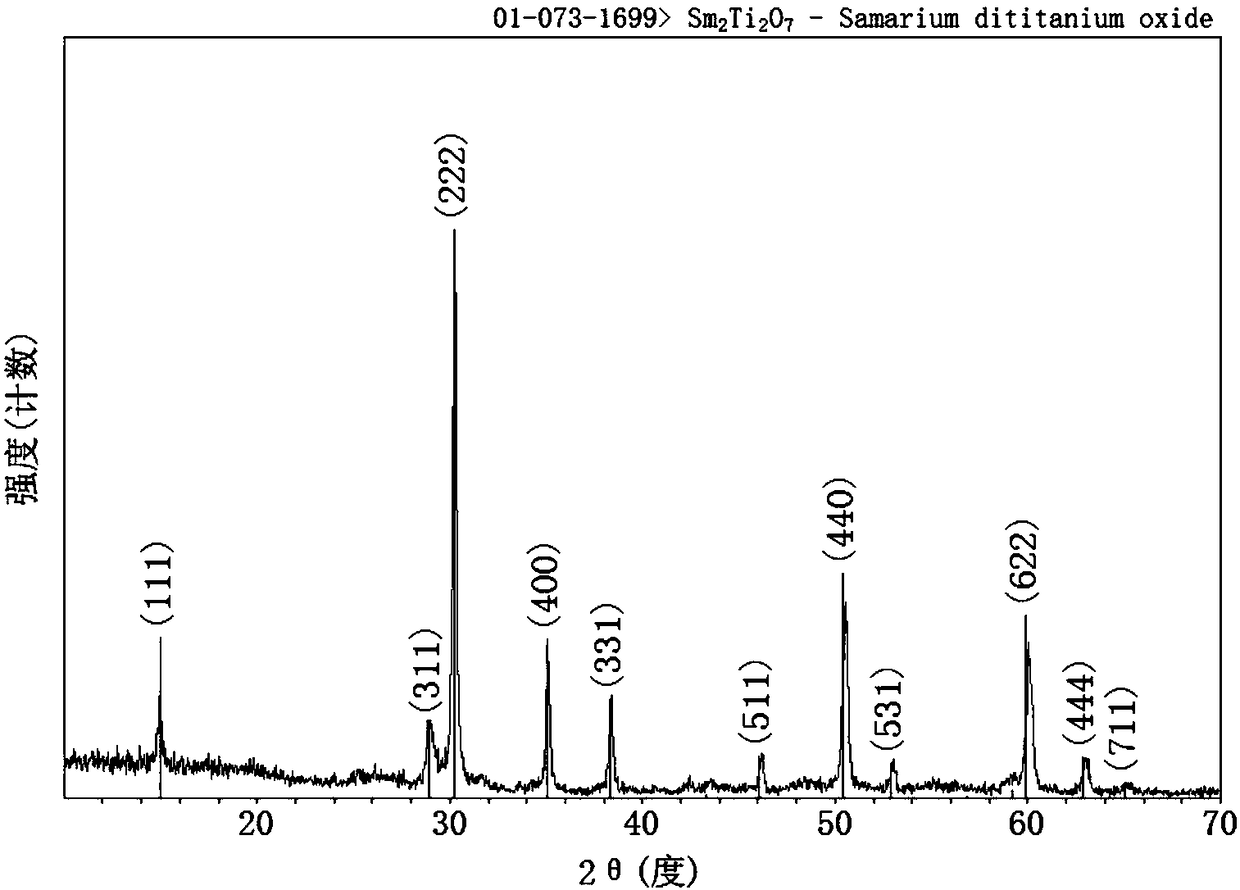

[0035] Such as figure 1 As shown, the obtained powder is scanned between 10-70 degrees by X-ray diffractometer, and the powder sample shows polycrystalline diffraction characteristics, and all diffraction peaks and Sm ...

Embodiment 2

[0037] Dissolve samarium nitrate and tetrabutyl titanate in 10 ml of acetic acid at a molar ratio of 1:1.1, and stir magnetically in a water bath to form a transparent solution; adjust the temperature of the water bath to 4°C, and slowly add ammonia water to the transparent In the solution, produce milky white product in the solution, continue to add ammoniacal liquor until the pH value of whole system is neutral, completes reaction. Subsequently, the reacted solution was subjected to solid-liquid separation with a centrifuge at a centrifugation rate of 10,000 rpm to obtain a white powder. The white powder was dried at 80°C for 2 hours, then transferred to a muffle furnace, and calcined at 750°C for 2 hours to obtain light yellow Sm 2 Ti 2 o 7 Nano powder. The grain size obtained by calculating the half width of the diffraction peak is 35 nm.

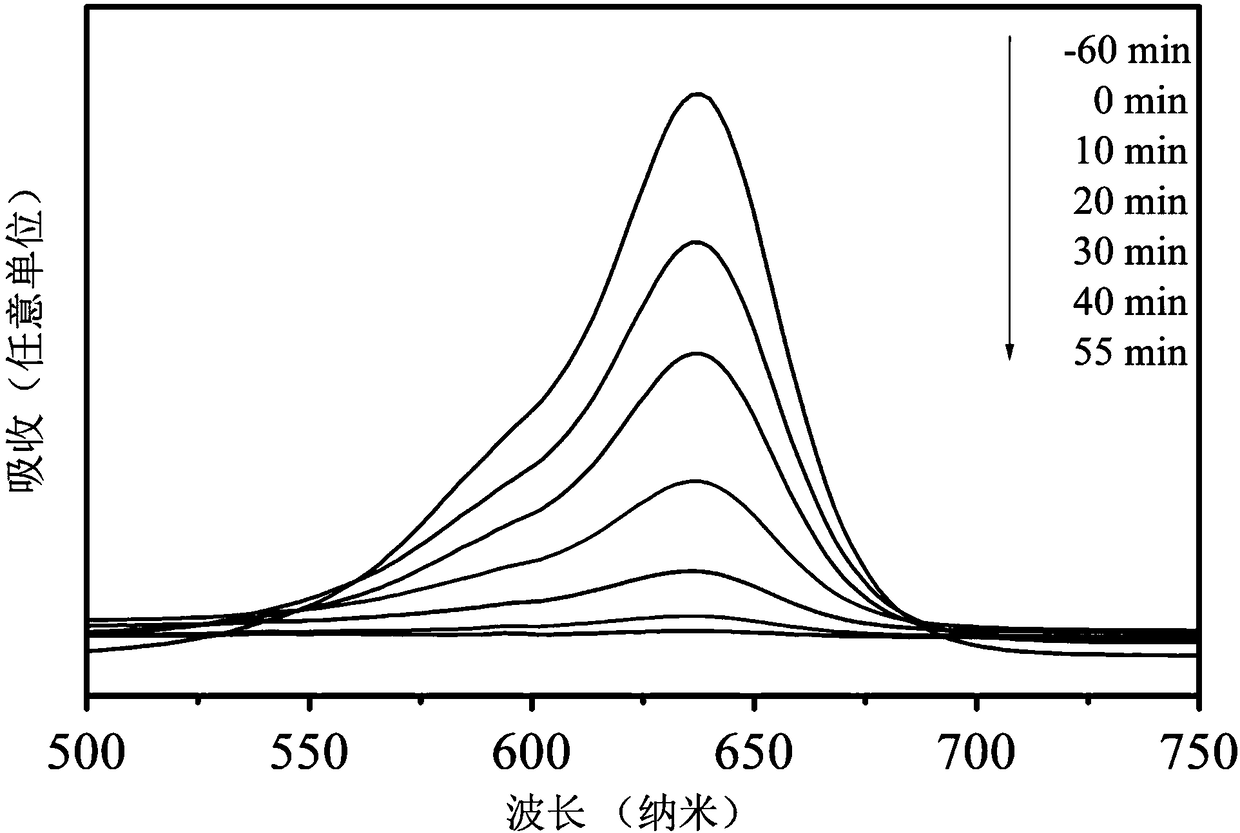

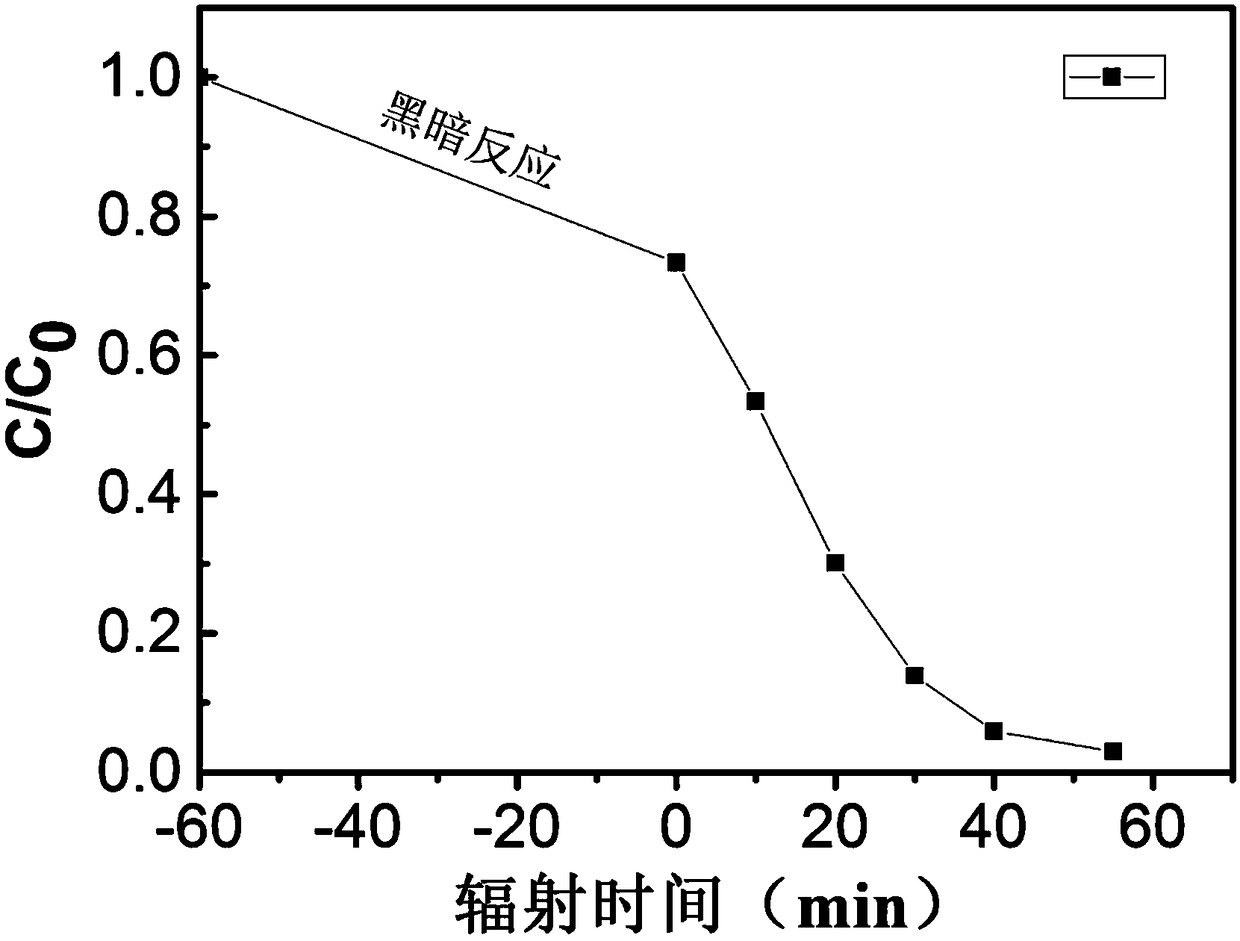

[0038] figure 2 Given the obtained Sm 2 Ti 2 o 7 The absorption spectra of nanopowders for organic dye rhodamine after differ...

Embodiment 3

[0040] Dissolve samarium nitrate and tetrabutyl titanate in 10 ml of acetic acid at a molar ratio of 1:1.3, and stir magnetically in a water bath to form a transparent solution; adjust the temperature of the water bath to 25°C, and slowly add ammonia water to the transparent In the solution, produce milky white product in the solution, continue to add ammoniacal liquor until the pH value of whole system is neutral, completes reaction. Subsequently, the reacted solution was subjected to solid-liquid separation with a centrifuge at a centrifugation rate of 6000 rpm to obtain a white powder. The white powder was dried at 80°C for 2 hours, then transferred to a muffle furnace, and calcined at 850°C for 4 hours to obtain a light yellow Sm 2 Ti 2 o 7 Nano powder. The grain size obtained by calculating the half width of the diffraction peak is 45 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com