Preparation method of alternately growing ferroelectric film

A ferroelectric thin film and alternate growth technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of poor ferroelectricity and durability, and achieve low error rate, low experimental hardware conditions and low cost requirements , The effect of chemical composition is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

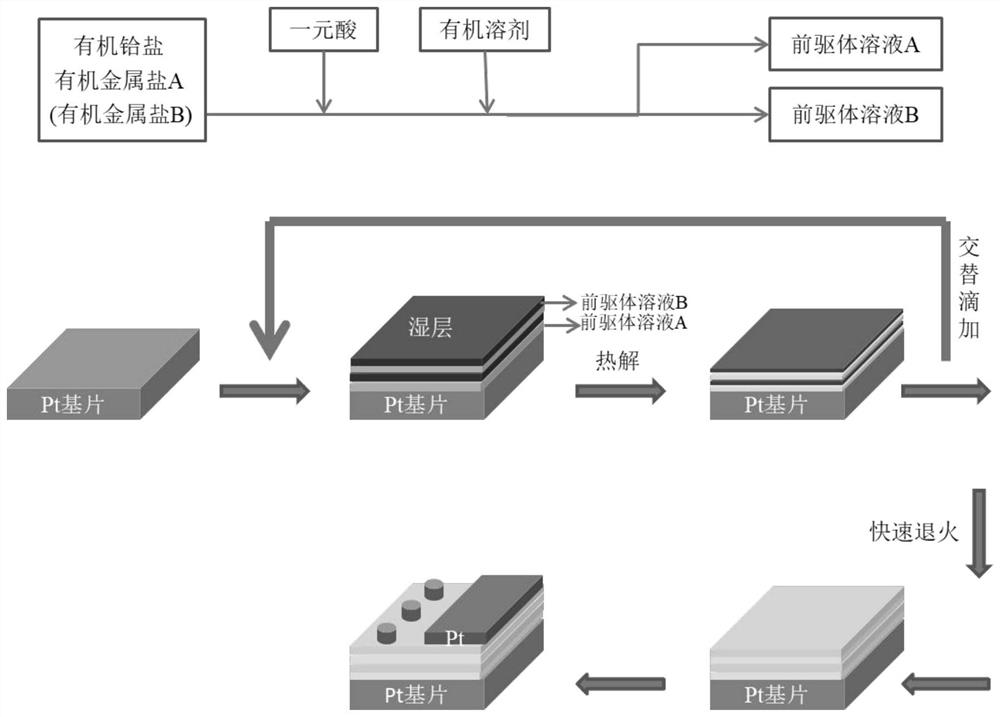

[0043] The invention provides a method for preparing an alternately grown ferroelectric thin film, comprising the following steps:

[0044] 1) Coating the precursor solution A on the platinum substrate and then annealing to obtain the annealed A film sample;

[0045] 2) coating the precursor solution B on the annealed A film sample, and obtaining the annealed AB film sample after annealing;

[0046] The precursor solution A and the precursor solution B independently contain organic hafnium salts, organic metal salts of multi-doping elements, monobasic acids and organic solvents;

[0047] The organometallic salts of multiple doping elements in the precursor solution A and the precursor solution B are different;

[0048] 3) Taking step 1) and step 2) as a unit, repeat n-1 times to obtain (AB) n Thin film samples, for containing (AB) n The sample of the thin film is annealed to obtain an alternately grown ferroelectric thin film;

[0049] Said n≥2.

[0050] In the present inve...

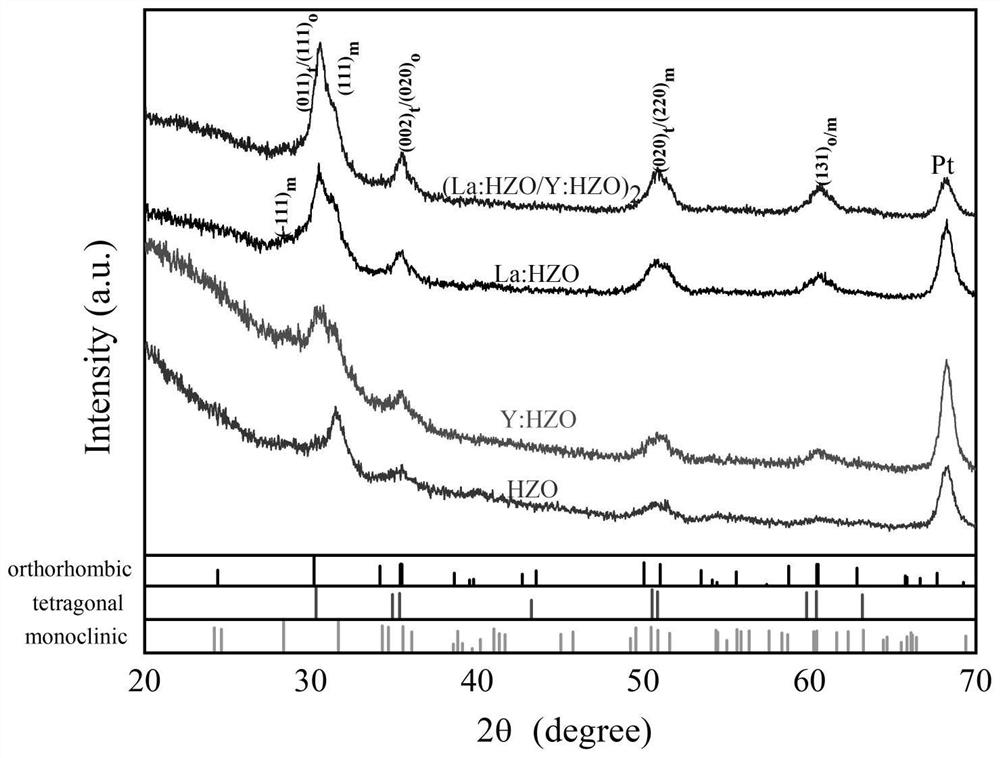

Embodiment 1

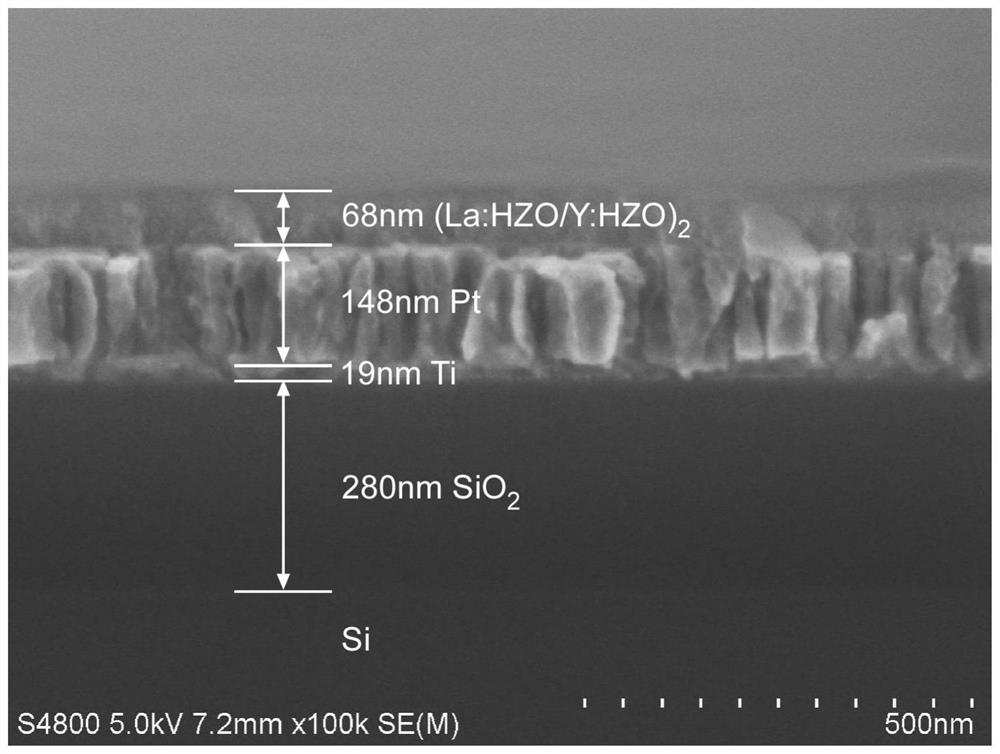

[0077] Step S1: Beaker A: Use an analytical balance to weigh 0.1416g hafnium acetylacetonate, 0.1201g zirconium acetylacetonate and 0.0032g hydrate of lanthanum acetylacetonate into the beaker, then add 3ml acetic acid and 2ml acetylacetone in sequence; beaker B: use the analytical Weigh 0.1416g hafnium acetylacetonate, 0.1201g zirconium acetylacetonate and 0.0029g yttrium acetylacetonate hydrate into a beaker, then add 3ml acetic acid and 2ml acetylacetone in sequence.

[0078] Step S2: Seal the two beakers and place them in a constant temperature magnetic stirring water bath for stirring. Set the stirring temperature to 55°C respectively. Stir for 35 minutes until the solution is clear. Take out the two beakers and place them on a common magnetic stirring device for stirring for more than 2 hours. Set to room temperature to obtain precursor solution A (lanthanum acetylacetonate) and precursor solution B (yttrium acetylacetonate).

[0079] Step S3: use a 1ml dropper to drop t...

Embodiment 2

[0095] Step S1: Beaker A: Use an analytical balance to weigh 0.1416g hafnium acetylacetonate, 0.1201g zirconium acetylacetonate and 0.0032g hydrate of lanthanum acetylacetonate into the beaker, then add 3ml acetic acid and 2ml acetylacetone in sequence; beaker B: use the analytical Weigh 0.1416g hafnium acetylacetonate, 0.1201g zirconium acetylacetonate and 0.0029g strontium acetylacetonate hydrate into a beaker, then add 3ml acetic acid and 2ml acetylacetone in sequence.

[0096] Step S2 to step S9 are the same as embodiment 1;

[0097] Step S10: the obtained step S9 containing (AB) 2 The thin film samples were placed in a rapid annealing furnace and annealed for 290 seconds at a time in an oxygen environment at a temperature of 350°C.

[0098] Step S11: Put the thin film sample obtained in step S10 into a rapid annealing furnace, anneal for 250 seconds in an oxygen environment at a temperature of 600° C., and then cool with the furnace to obtain a molar doping ratio of La:(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com