Weather-resistant silver mirror and preparation method thereof

A silver mirror and weather-resistant technology, which is applied in mirrors, optics, instruments, etc., can solve the problems of multi-element multi-layer coating that cannot adapt to weather-resistant silver mirrors, and achieve the effect of improving reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

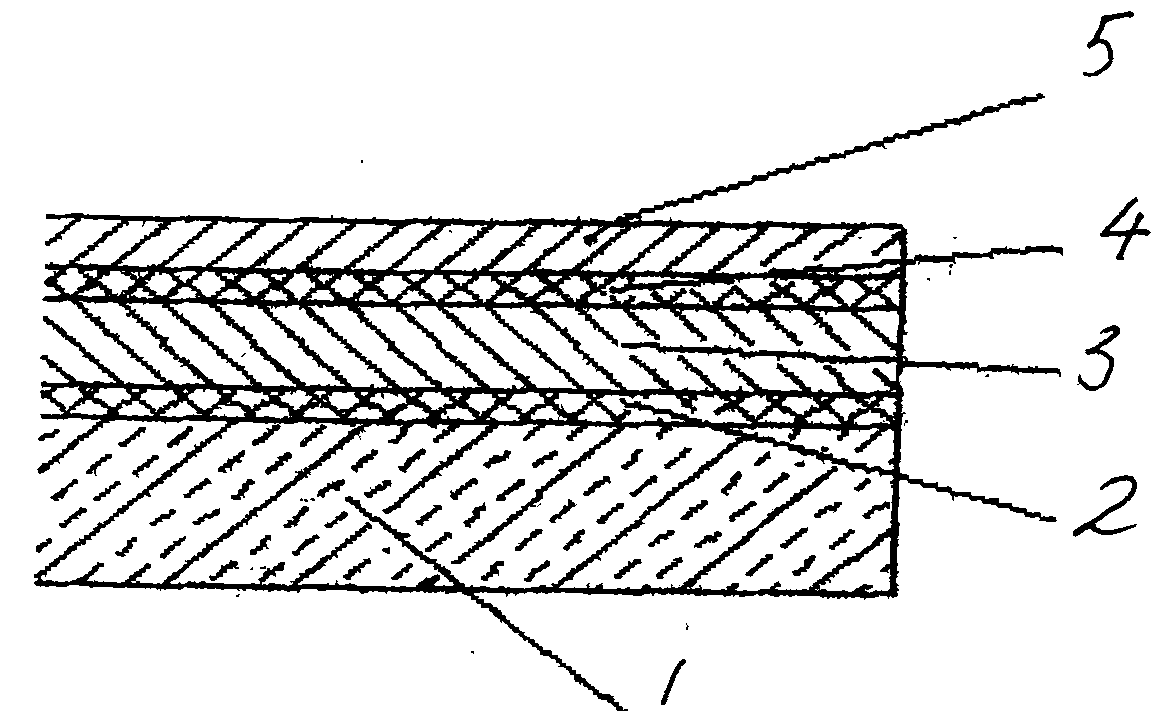

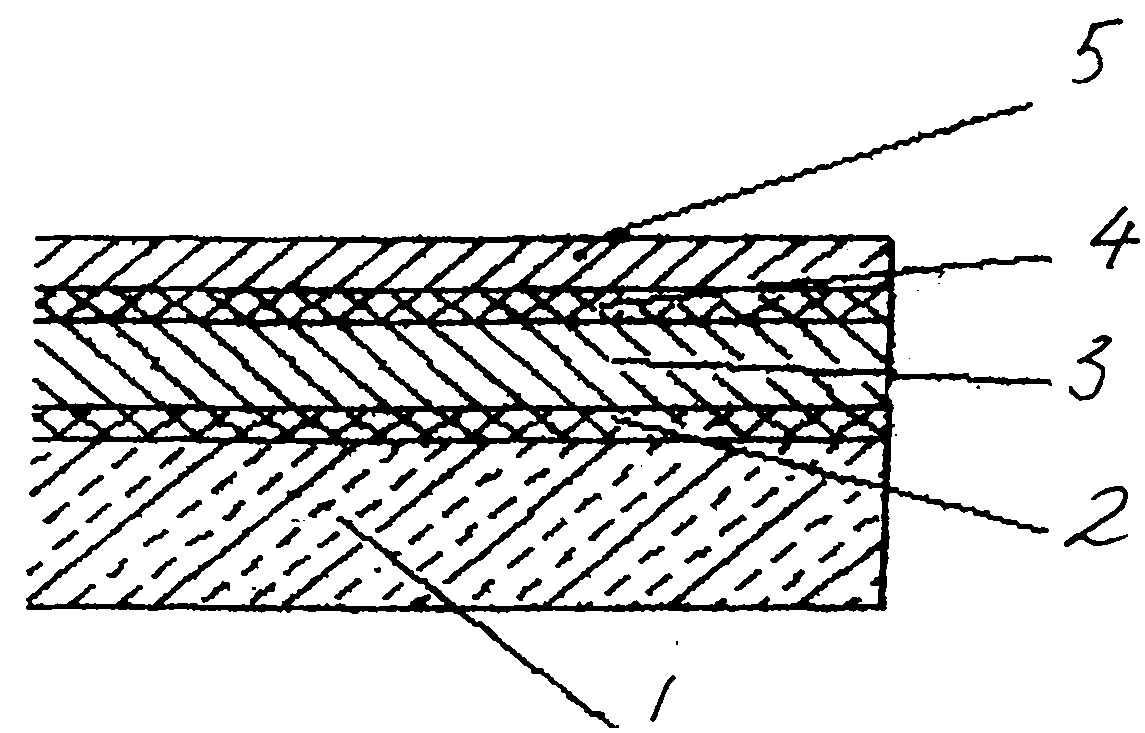

[0033] One of the embodiments, as attached figure 1 Shown:

[0034] A weather-resistant silver mirror especially suitable for trough solar thermal power generation technology and equipment, comprising a transparent substrate 1, and a first Al plated on one side of the transparent substrate 1 2 O 3 Adhesive layer 2, plated on the first Al 2 O 3 The Ag reflective layer 3 on the surface of the adhesive layer 2, and the second Al plated on the surface of the Ag reflective layer 3 2 O 3 Adhesive protective layer 4, second Al 2 O 3 The surface of the adhesive protection layer 4 is coated with a SiOx protection layer 5. On the surface of the SiOx layer 5, at least two waterproof protective polymer paint layers 6 are also coated. The SiOx protective layer 5 is SiO 2 The protective layer. When the polymer paint layer 6 is two layers, the inner polymer paint layer 6-1 is a two-component epoxy quick-drying silver mirror protective paint UE307 layer, and the outer polymer paint layer 6-2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com