Preparation method of yttrium phosphate vanadate europium-doped or samarium-doped luminescent microspheres

A technology of luminescent microspheres and yttrium phosphovanadate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of uneven morphology of yttrium phosphovanadate-doped europium or samarium luminescent microspheres, affecting the intensity of luminescent powder, etc. Achieve the effect of being suitable for large-scale production, low equipment requirements, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

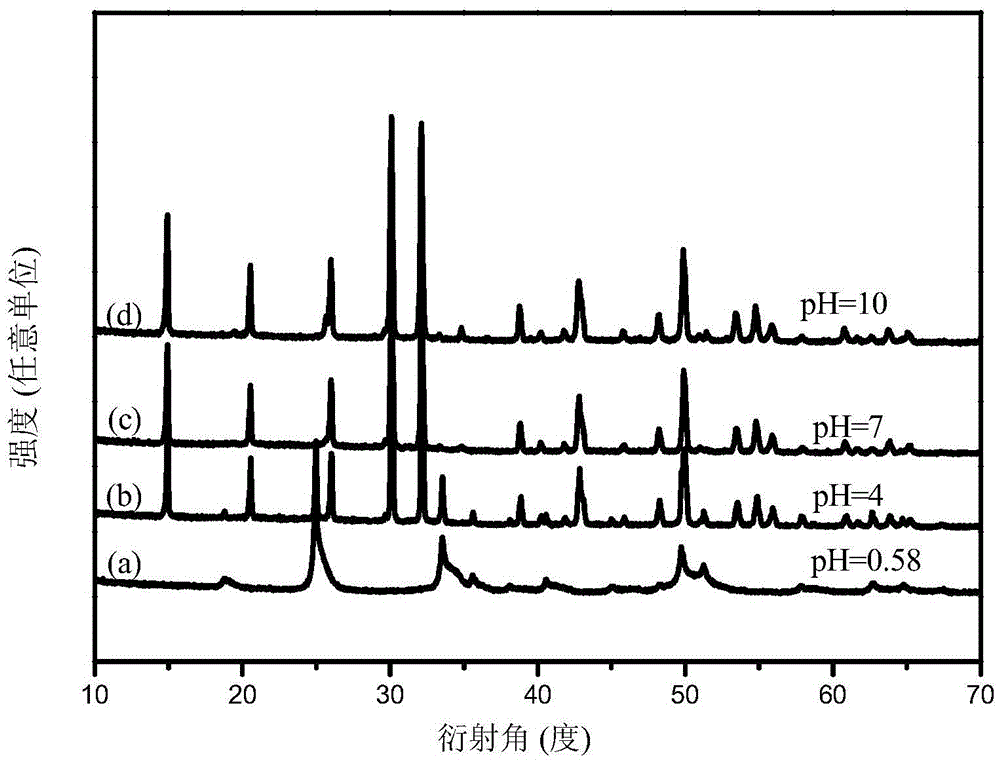

[0044] A red europium-doped yttrium phosphovanadate luminescent microsphere, its chemical formula is Y 0.95 Eu 0.05 P 0.3 V 0.7 o 4 .

[0045] The above-mentioned preparation method of red europium-doped yttrium phosphovanadate luminescent microspheres specifically comprises the following steps:

[0046] Adding yttrium oxide and europium oxide into the dilute nitric acid solution, stirring and dissolving under heating conditions, respectively preparing yttrium nitrate solution with a concentration of 0.4±0.01mol / L and europium nitrate solution with a concentration of 0.05±0.001mol / L;

[0047] Measure 4.75±0.01ml of yttrium nitrate and 2.00±0.01ml of europium nitrate solution in a beaker, stir and mix thoroughly to obtain a mixed solution;

[0048] Add 0mmol EDTA to the mixed solution obtained above, and stir for 1h;

[0049] Dissolve 1.4mmol ammonium metavanadate and 0.6mmol ammonium dihydrogen phosphate in nitric acid solution, stir to dissolve, add the mixed solution o...

Embodiment 2

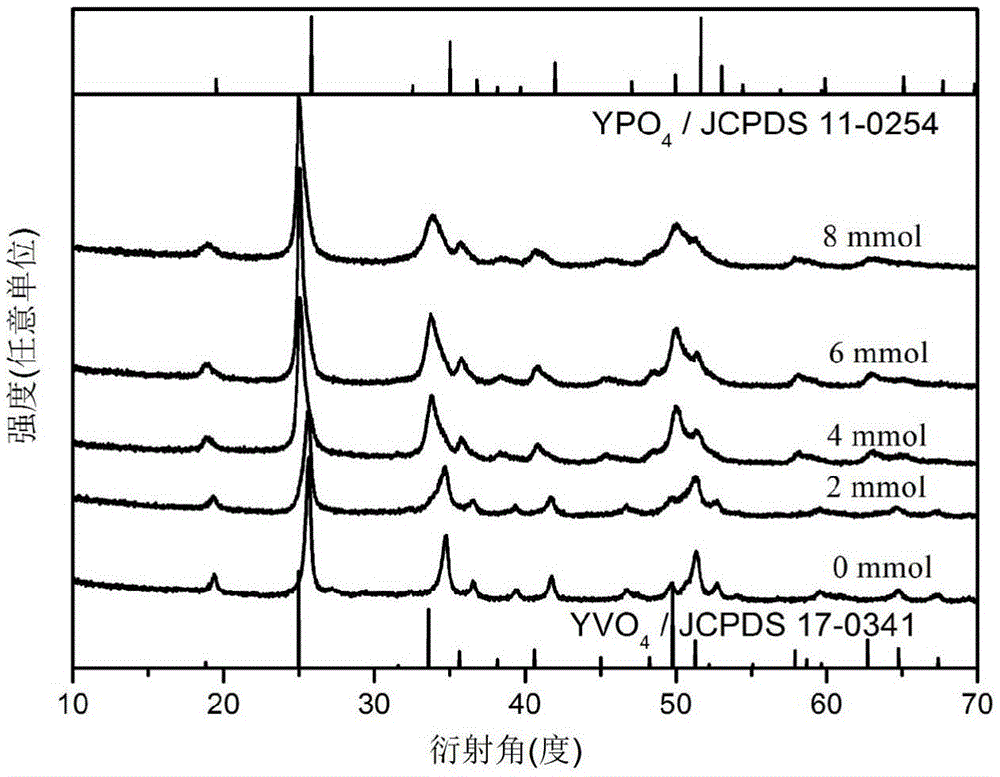

[0053] A red europium-doped yttrium phosphovanadate luminescent microsphere, its chemical formula is Y 0.95 Eu 0.05 P 0.3 V 0.7 o 4 .

[0054] The above-mentioned preparation method of red europium-doped yttrium phosphovanadate luminescent microspheres specifically comprises the following steps:

[0055] Adding yttrium oxide and europium oxide into the dilute nitric acid solution, stirring and dissolving under heating conditions, respectively preparing yttrium nitrate solution with a concentration of 0.4±0.01mol / L and europium nitrate solution with a concentration of 0.05±0.001mol / L;

[0056] Measure 4.75±0.01ml of yttrium nitrate and 2.00±0.01ml of europium nitrate solution in a beaker, stir and mix thoroughly to obtain a mixed solution;

[0057] Add 2±0.01mmol EDTA to the mixed solution obtained above, and stir for 1h;

[0058] Dissolve 1.4mmol ammonium metavanadate and 0.6mmol ammonium dihydrogen phosphate in nitric acid solution, stir to dissolve, add the mixed solut...

Embodiment 3

[0061] A red europium-doped yttrium phosphovanadate luminescent microsphere, its chemical formula is Y 0.95 Eu 0.05 P 0.3 V 0.7 o 4 .

[0062] The above-mentioned preparation method of red europium-doped yttrium phosphovanadate luminescent microspheres specifically comprises the following steps:

[0063] Adding yttrium oxide and europium oxide into the dilute nitric acid solution, stirring and dissolving under heating conditions, respectively preparing yttrium nitrate solution with a concentration of 0.4±0.01mol / L and europium nitrate solution with a concentration of 0.05±0.001mol / L;

[0064] Measure 4.75±0.01ml of yttrium nitrate and 2.00±0.01ml of europium nitrate solution in a beaker, stir and mix thoroughly to obtain a mixed solution;

[0065] Add 4±0.01mmol EDTA to the mixed solution obtained above, and stir for 1h;

[0066] Dissolve 1.4mmol ammonium metavanadate and 0.6mmol ammonium dihydrogen phosphate in nitric acid solution, stir to dissolve, add the mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com