Preparation method of CIST nano wire

A technology of tellurium nanowires and copper indium selenide, which is applied in the field of new-generation thin-film solar cell materials, can solve the problems of not being nanowires, and achieve the effect of simple operation process and cheap equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

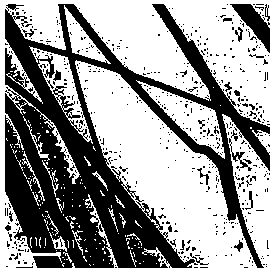

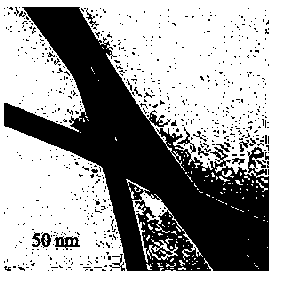

Image

Examples

Embodiment 1

[0034] 1. Preparation of catalyst - toluene solution of bismuth nanoparticles:

[0035]Mix 0.5 mL of 1 mol / L bis(trimethylsilyl)amide bismuth solution in tetrahydrofuran with 2 mL of bis(trimethylsilyl)amide bismuth content of 1 mol / L The tetrahydrofuran solution of sodium bis(trimethylsilyl)amide of L was mixed to form a mixed solution containing bismuth precursor, which was placed in a syringe.

[0036] Another 5 g of polyvinylpyrrolidone-hexadecane block copolymer and 15 g of diphenyl ether were magnetically stirred and heated to 180° C. under nitrogen protection to form a reaction system.

[0037] The mixed solution containing bismuth precursor was injected into the reaction system, and the solution changed color rapidly to black. After reacting for 30 minutes, remove the heat source, cool to room temperature, then add 30mL of methanol and centrifuge, use a mixed solvent of toluene and methanol to repeatedly disperse and centrifuge for 3 to 4 times, and centrifuge the pha...

Embodiment 2

[0049] 1. Preparation of catalyst - toluene solution of bismuth nanoparticles:

[0050] Mix 0.5 mL of 1 mol / L bis(trimethylsilyl)aminobismuth tetrahydrofuran solution with a content of bis(trimethylsilyl)amide bismuth and 2 mL of bis(trimethylsilyl)amide with a content of 1 mol / L The tetrahydrofuran solution of sodium bis(trimethylsilyl)amide of L was mixed to form a mixed solution containing bismuth precursor, which was placed in a syringe.

[0051] Another 5 g of polyvinylpyrrolidone-hexadecane block copolymer and 15 g of diphenyl ether were magnetically stirred and heated to 180° C. under the protection of nitrogen to form a reaction system.

[0052] The mixed solution containing bismuth precursor was injected into the reaction system, and the solution changed color rapidly to black. After reacting for 30 minutes, remove the heat source, cool to room temperature, then add 30mL of methanol and centrifuge, use a mixed solvent of toluene and methanol to repeatedly disperse an...

Embodiment 3

[0064] 1. Preparation of catalyst - toluene solution of bismuth nanoparticles:

[0065] Mix 0.5 mL of 1 mol / L bis(trimethylsilyl)aminobismuth tetrahydrofuran solution with a content of bis(trimethylsilyl)amide bismuth and 2 mL of bis(trimethylsilyl)amide with a content of 1 mol / L The tetrahydrofuran solution of sodium bis(trimethylsilyl)amide of L was mixed to form a mixed solution containing bismuth precursor, which was placed in a syringe.

[0066] Another 5 g of polyvinylpyrrolidone-hexadecane block copolymer and 15 g of diphenyl ether were magnetically stirred and heated to 180° C. under the protection of nitrogen to form a reaction system.

[0067] The mixed solution containing bismuth precursor was injected into the reaction system, and the solution changed color rapidly to black. After reacting for 30 minutes, remove the heat source, cool to room temperature, then add 30mL of methanol and centrifuge, use a mixed solvent of toluene and methanol to repeatedly disperse an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com