Method for rapidly preparing single-phase Bi2S3 thermoelectric compound

A compound, single-phase technology, applied in bismuth compounds, chemical instruments and methods, thermoelectric device junction lead-out materials, etc., can solve the problems of serious S volatilization, the influence of sample performance repeatability, etc., and achieve fast reaction speed and low cost. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Rapid preparation of single-phase Bi 2 S 3 A method for thermoelectric compounds comprising the steps of:

[0027] 1) Prepare Bi powder and S powder as raw materials according to the stoichiometric ratio Bi:S=2:3.06 (relative to the compound Bi 2 S 3 For the stoichiometric ratio, the raw material sulfur powder is in excess of 2%), and then they are ground and mixed uniformly to obtain the reactant, which is pressed into a 10mm cylindrical block with a total mass of 4.3g;

[0028] 2 Put the block reactant in step 1) in a glass tube to heat the end of the block in an air atmosphere, and perform local detonation to initiate a self-propagating reaction. After the reaction is completed, it is naturally cooled to obtain a single-phase Bi 2 S 3 thermoelectric compound.

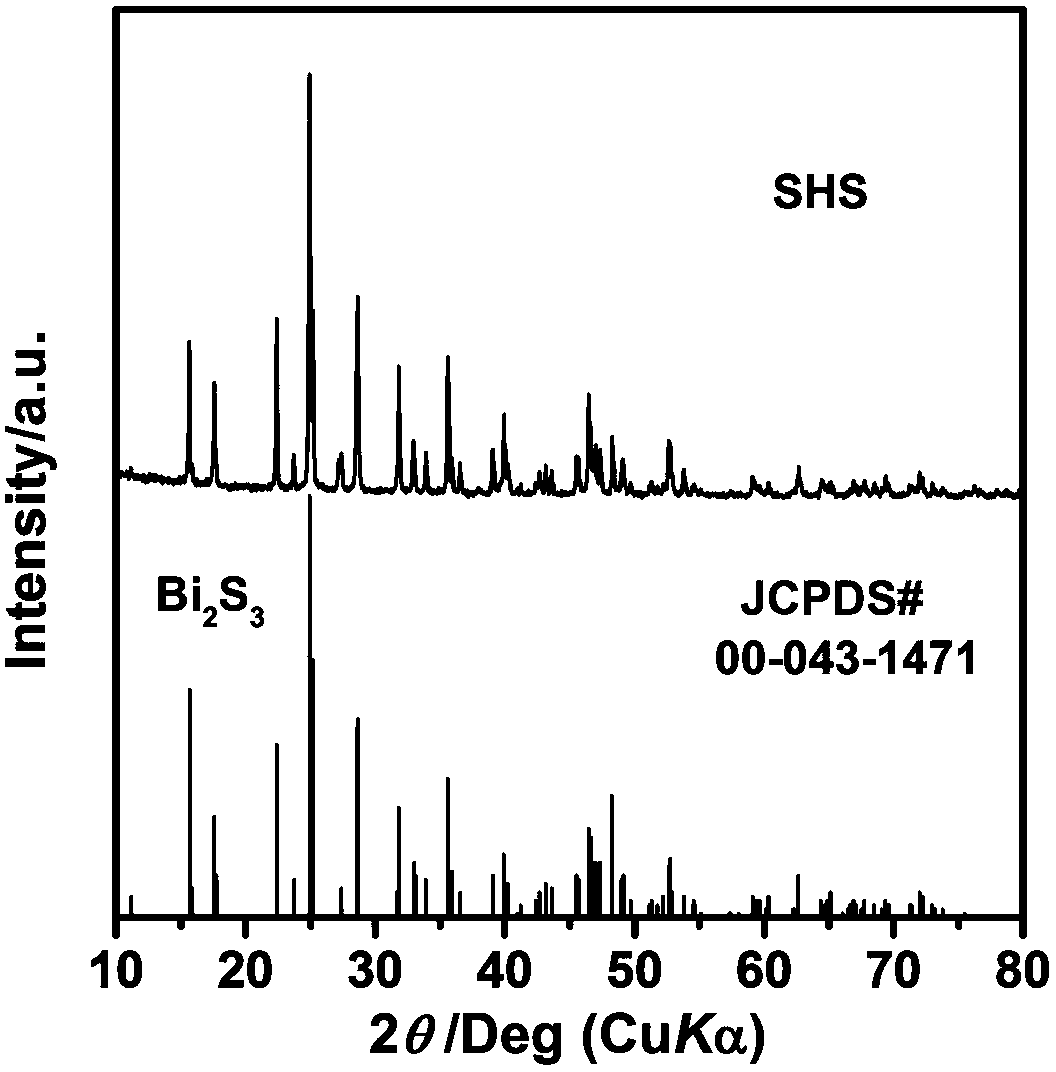

[0029] Figure 1 (a) and (b) are the XRD pattern and SEM pattern of the self-propagating reaction powder obtained in step 3) in Example 1, respectively (magnified by 5.00 k times and 10.00 k times from lef...

Embodiment 2

[0031] Rapid preparation of single-phase Bi 2 S 3 A method for thermoelectric compounds comprising the steps of:

[0032] 1) Prepare Bi powder and S powder as raw materials according to the stoichiometric ratio Bi:S=2:3.06, then grind and mix them evenly to obtain reactants, and press them into 10mm cylindrical blocks with a total mass of 4.3g;

[0033] 2. Vacuum-seal the block reactant in step 1) in a glass tube, and place it in a constant temperature furnace for overall heating to promote a thermal explosion reaction. The furnace temperature and reaction time are respectively: 500°C, 2min, and naturally cool after the reaction is completed. get single-phase Bi 2 S 3 thermoelectric compound.

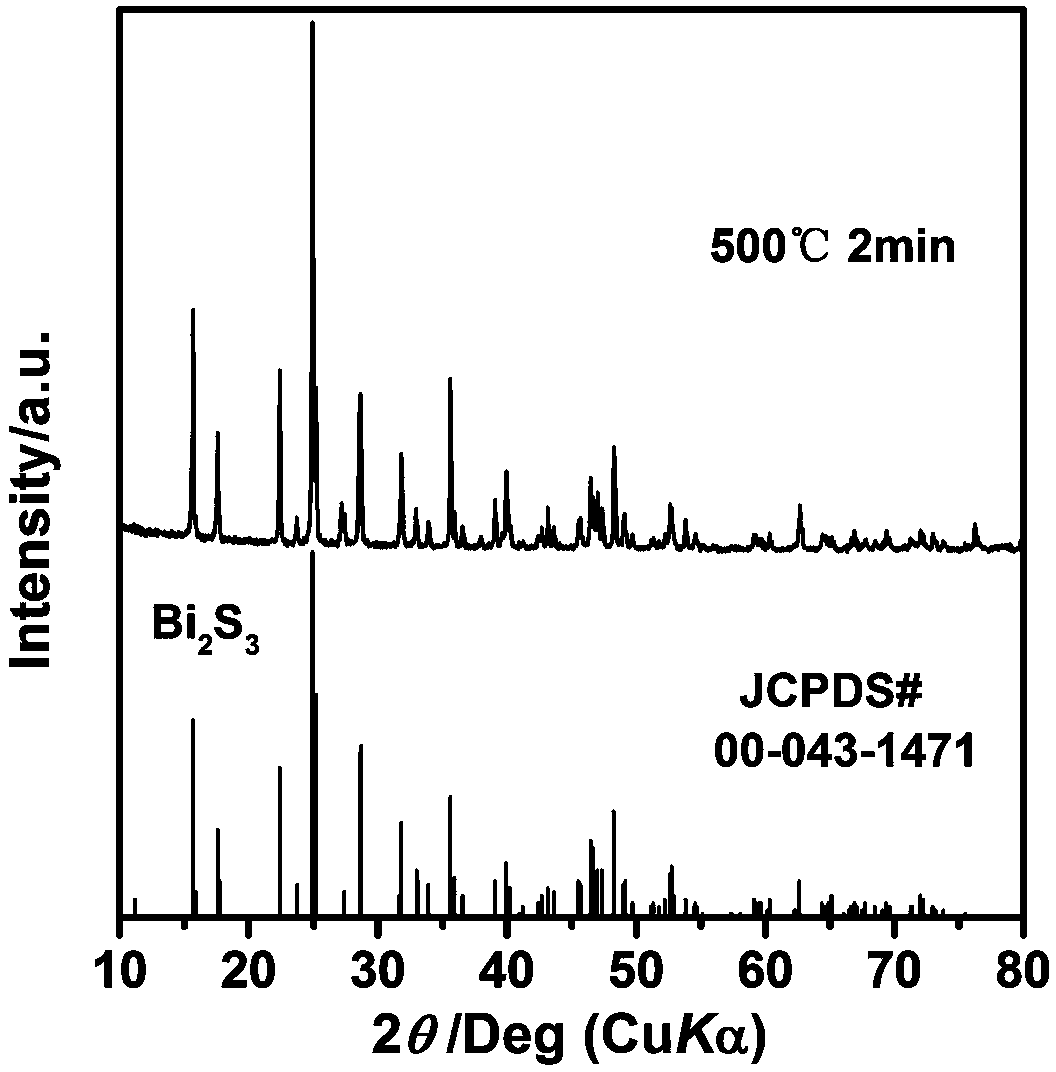

[0034] Figure 2 (a) and (b) are the XRD pattern and SEM pattern of the powder after thermal explosion reaction obtained in step 3) in Example 2, respectively (magnified by 5.00 k times and 10.00 k times from left to right, respectively). It can be seen from Figure 2 that the obtain...

Embodiment 3

[0036] Rapid preparation of single-phase Bi 2 S 3 A method for thermoelectric compounds comprising the steps of:

[0037] 1) Prepare Bi powder and S powder as raw materials according to the stoichiometric ratio Bi:S=2:3.06, then grind and mix them evenly to obtain reactants, and press them into 10mm cylindrical blocks with a total mass of 4.3g;

[0038] 2. Vacuum-seal the block reactant in step 1) in a glass tube, and place it in a constant temperature furnace for overall heating to promote a thermal explosion reaction. The furnace temperature and reaction time are respectively: 500°C, 3min, and naturally cool after the reaction is completed. get single-phase Bi 2 S 3 thermoelectric compound.

[0039] Figure 3(a) and (b) are the XRD pattern and SEM pattern of the powder after the thermal explosion reaction obtained in step 3) of Example 3, respectively (magnified by 5.00 k times and 10.00 k times from left to right, respectively). It can be seen from Figure 3 that the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com