Shining thermal barrier coating system of rare earth niobate based on defective fluorite structure and preparation method of shining thermal barrier coating system

A technology of fluorite structure and thermal barrier coating, which is applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of low thermal conductivity and high thermal stability, and achieve low thermal conductivity and chaos The effect of high and excellent oxygen barrier capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

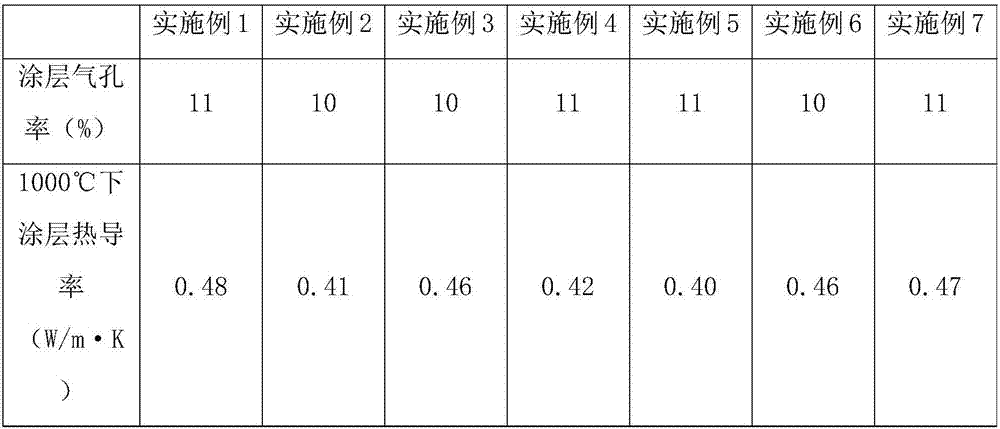

Examples

Embodiment 1

[0027] (1) Calcinate Y2O3 and Nb2O3 powders at 1000°C for 1 hour, mix them according to the stoichiometric ratio, use absolute ethanol as a mixed graft, and use zirconia as the ball milling medium for ball milling, wherein the total volume of balls is 45-45% of the volume of the ball mill tank 55% at a rotational speed of 300r / min to obtain a mixed slurry, which was subjected to rotary evaporation and dried in a drying oven at 120°C for 12 hours, and passed through a 400-mesh sieve to obtain a pre-sintered powder.

[0028] (2) The pre-sintered powder is held at 20MPa for 5 minutes, and dry-pressed into a disc with a diameter of 15mm and a thickness of 2mm. The formed green body is placed in a dry box for 24 hours after being held at 220MPa for 2 minutes to release the static pressure generated during the process. The internal stress is obtained green body.

[0029] (3) The green body is sintered in air without pressure, the sintering temperature parameter is from room temperat...

Embodiment 2

[0032] (1) Calcinate Yb2O3 and Nb2O3 powders at 1000°C for 1 hour, mix them according to the stoichiometric ratio, use absolute ethanol as a mixed graft, and use zirconia as a ball milling medium for ball milling mixture, wherein the total volume of balls is 45-45% of the volume of the ball mill tank 55% at a rotational speed of 300r / min to obtain a mixed slurry, which was subjected to rotary evaporation and dried in a drying oven at 120°C for 12 hours, and passed through a 400-mesh sieve to obtain a pre-sintered powder.

[0033] (2) The pre-sintered powder is held at 20MPa for 5 minutes, and dry-pressed into a disc with a diameter of 15mm and a thickness of 2mm. The formed green body is placed in a dry box for 24 hours after being held at 220MPa for 2 minutes to release the static pressure generated during the process. The internal stress is obtained green body.

[0034] (3) The green body is sintered in air without pressure, the sintering temperature parameter is from room t...

Embodiment 3

[0037] (1) Calcinate Gd2O3 and Nb2O3 powders at 1000°C for 1 hour, mix them according to the stoichiometric ratio, use absolute ethanol as a mixed graft, and use zirconia as the ball milling medium for ball milling, wherein the total volume of balls is 45-45% of the volume of the ball mill tank 55% at a rotational speed of 300r / min to obtain a mixed slurry, which was subjected to rotary evaporation and dried in a drying oven at 120°C for 12 hours, and passed through a 400-mesh sieve to obtain a pre-sintered powder.

[0038] (2) The pre-sintered powder is held at 20MPa for 5 minutes, and dry-pressed into a disc with a diameter of 15mm and a thickness of 2mm. The formed green body is placed in a dry box for 24 hours after being held at 220MPa for 2 minutes to release the static pressure generated during the process. The internal stress is obtained green body.

[0039] (3) The green body is sintered in air without pressure, the sintering temperature parameter is from room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com