N-type Mg3Sb2 alloy thermoelectric material and preparation method thereof

A technology of trimagnesium antimony and thermoelectric materials, which is applied in the field of N-type trimagnesium antimony alloy thermoelectric materials and its preparation, can solve problems such as interface phase defects and affecting material transport performance, and achieve simple dopant, Conducive to the effect of material stability and simple engineering method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also proposes a method for preparing the above-mentioned N-type antimony trimagnesium alloy thermoelectric material with high carrier concentration and high mobility, comprising the following steps:

[0060] (1) Vacuum packaging:

[0061] Weigh the elemental raw materials Mg, Bi, Sb and Y according to the stoichiometric ratio, use a tantalum tube with an outer diameter of 12 mm and a wall thickness of 0.5 mm with an elemental purity ≥ 99.95% and a length of about 5 cm, and use arc melting to seal the tantalum tube in an argon atmosphere At one end, put the elements required for sample preparation into the sealed tantalum tube at one end according to the ratio, and then use arc melting to seal the other end of the tantalum tube in an argon environment, and put the sealed tantalum tube into a quartz tube with an inner diameter of 15mm. Vacuum packaging in tube;

[0062] (2) Melt quenching:

[0063] Heating the quartz tube of the tantalum tube conta...

Embodiment 1

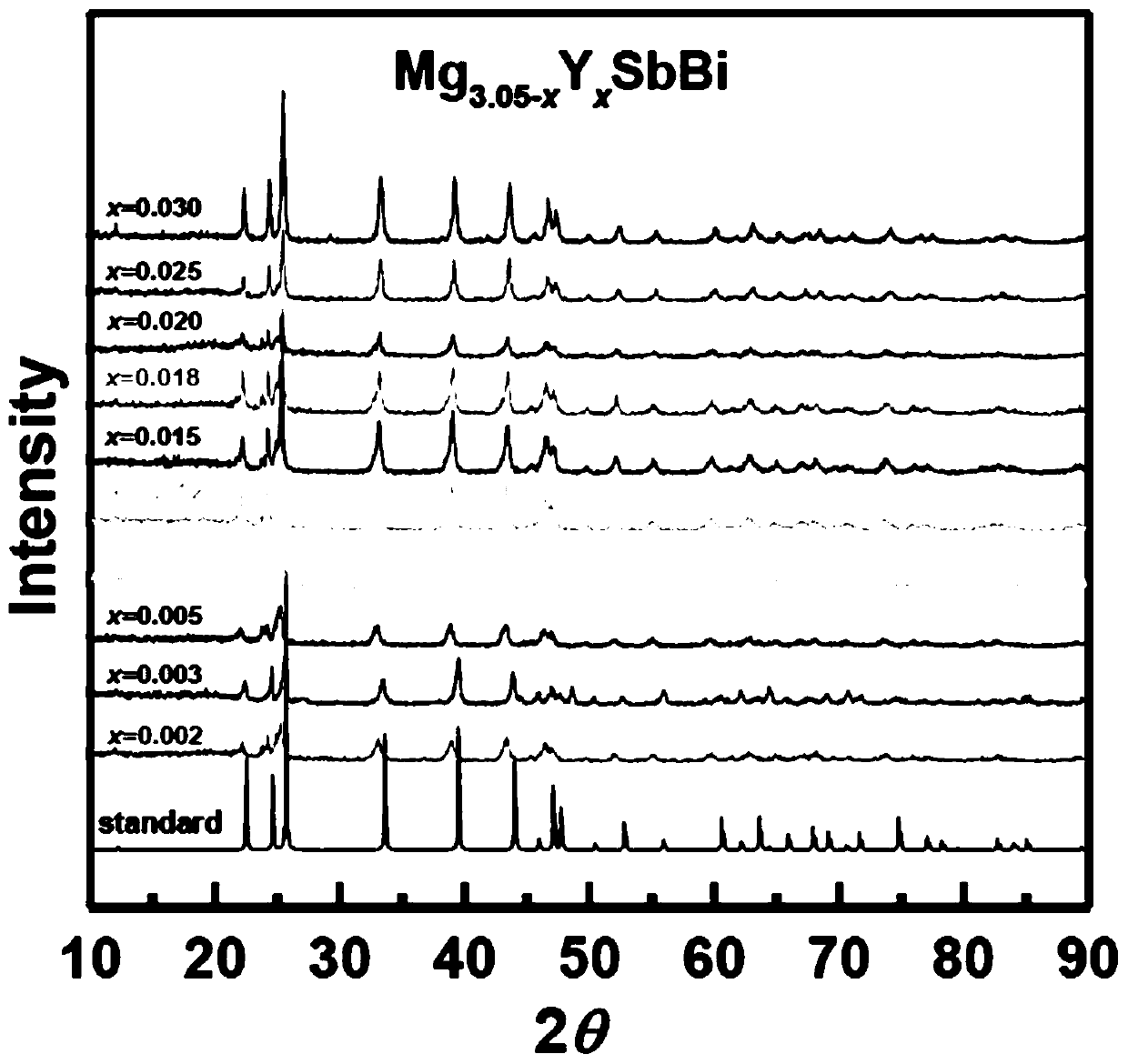

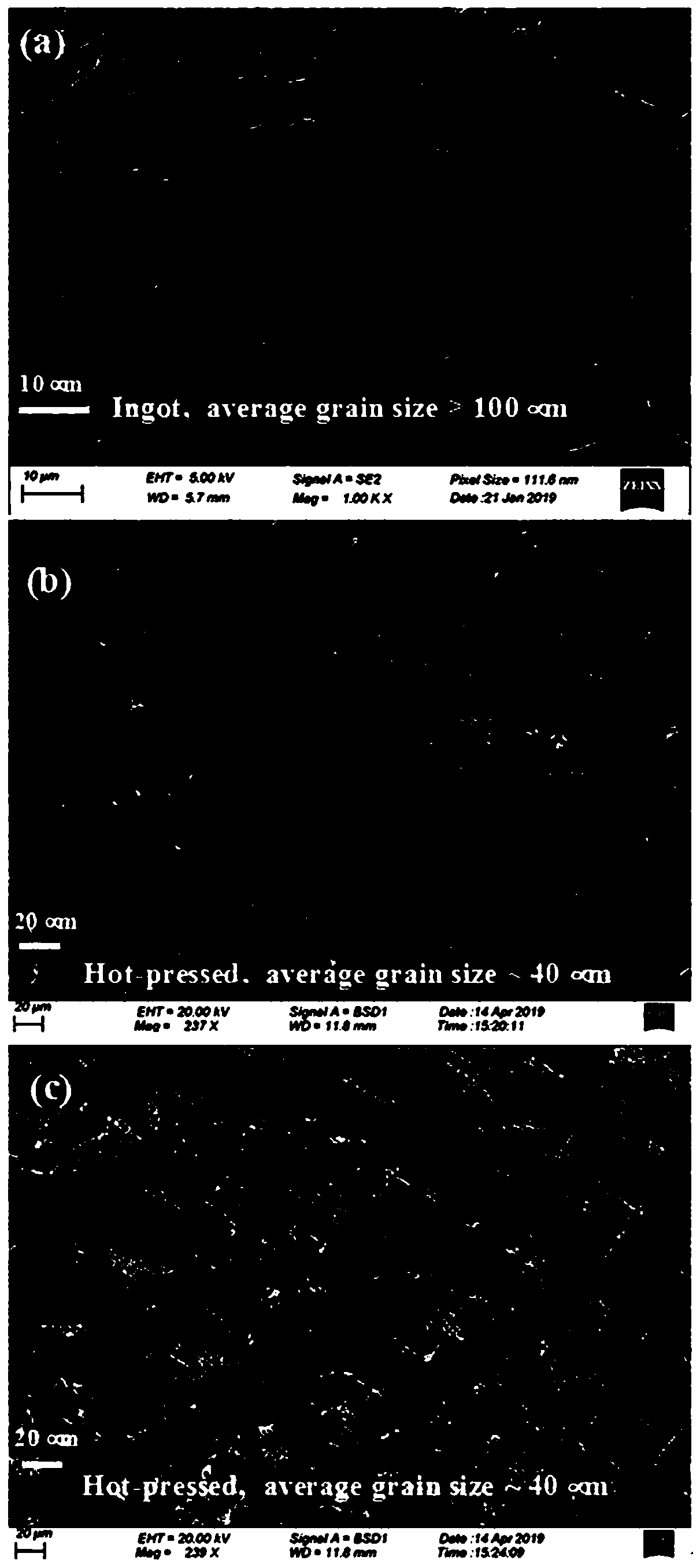

[0074] see Figure 4 As shown, a three-magnesium antimony alloy thermoelectric material, its chemical formula is Y x Mg 3.05-x SbBi, wherein, 0.002≤x≤0.03, in this embodiment, by taking x=0.002, 0.003, 0.005, 0.009, 0.012, 0.015, 0.018, 0.02, 0.025 and 0.03, that is, by changing different concentrations of Y to optimize the carrier Concentration and mobility, according to the following preparation method, Y with high carrier concentration x Mg 3.05-x SbBi bulk material:

[0075] (1) According to different x values, according to the chemical formula, it is Y x Mg 3.05-x The stoichiometric ratio of SbBi (0.002≤x≤0.03) Weigh the elemental raw materials Mg, Bi, Sb and Y with a purity greater than 99.99%, put them into tantalum tubes and vacuum seal them by arc melting, and then put the sealed tantalum tubes into quartz tube and vacuum packaged.

[0076](2) Hang the quartz tube containing the raw materials in a high-temperature well-type furnace, slowly raise the temperature...

Embodiment 2

[0100] Compared with Example 1, most of them are the same, except in this example:

[0101] In step (2), the temperature is slowly raised to 1000° C. at a rate of 150° C. per hour, kept at a temperature of 8 hours, and then rapidly quenched and cooled to obtain the first ingot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com