Locking structure for impeller of high-speed magnetic-levitation fan

A fan impeller and locking structure technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as increased unbalance of the rotor system, poor centering accuracy, and reduced ability of the impeller to resist centrifugal load , to achieve the effect of less material loss, reliable locking and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

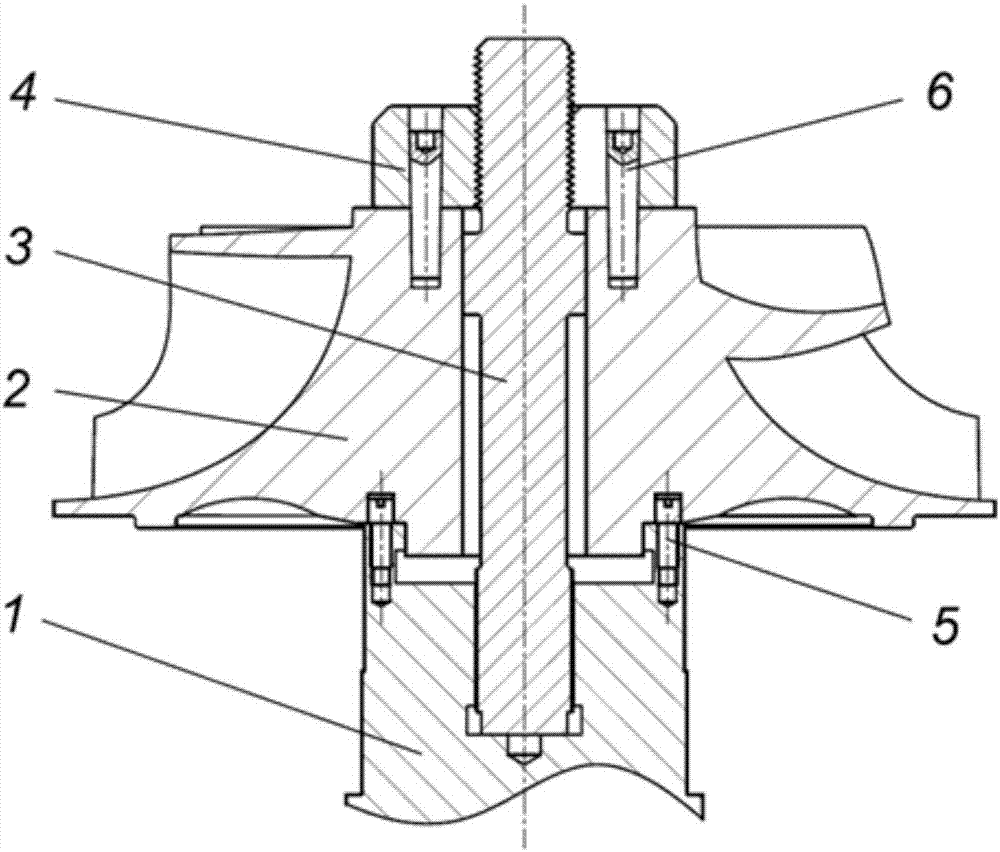

[0017] Such as figure 1 As shown, the high-speed maglev fan impeller locking structure of the present invention includes a rotor shaft 1 , an impeller 2 , a tie rod 3 , a nut 4 , a pin 5 , and a conical pin 6 . When installing, put the tie rod 3 into the screw hole at the end of the rotor shaft 1 until the bottom of the tie rod 3 touches the rotor shaft 1, install the pin 5 on the end of the rotor shaft 1, then install the impeller 2, and stretch the tie rod through the tensioner 3. After tightening the nut 4, use a drill bit to drill a hole on the impeller 2 through the hole reserved by the nut 4, and place the conical pin 6 with interference. When dismantling, firstly remove the conical pin 6 by a pin puller, then use a stretcher to elongate the pull rod 3 and then unscrew the nut 4, and finally remove the impeller 2, pull rod 3, and pin 5 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com