High entropy Half-Heusler thermoelectric material with low lattice thermal conductivity and preparation method thereof

A technology of thermoelectric materials and thermal conductivity, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, metal processing equipment, etc., and can solve the problems of inability to effectively adjust ZT value, low lattice, high thermal conductivity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

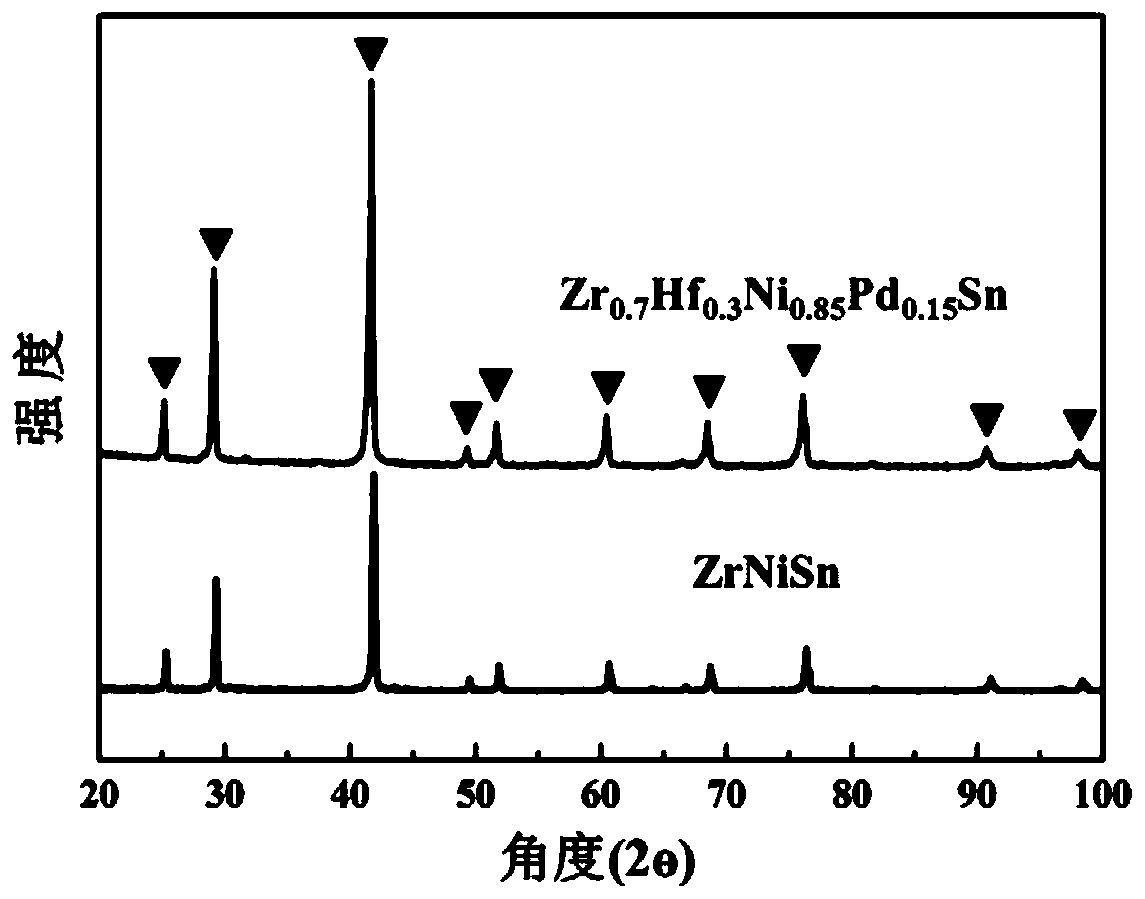

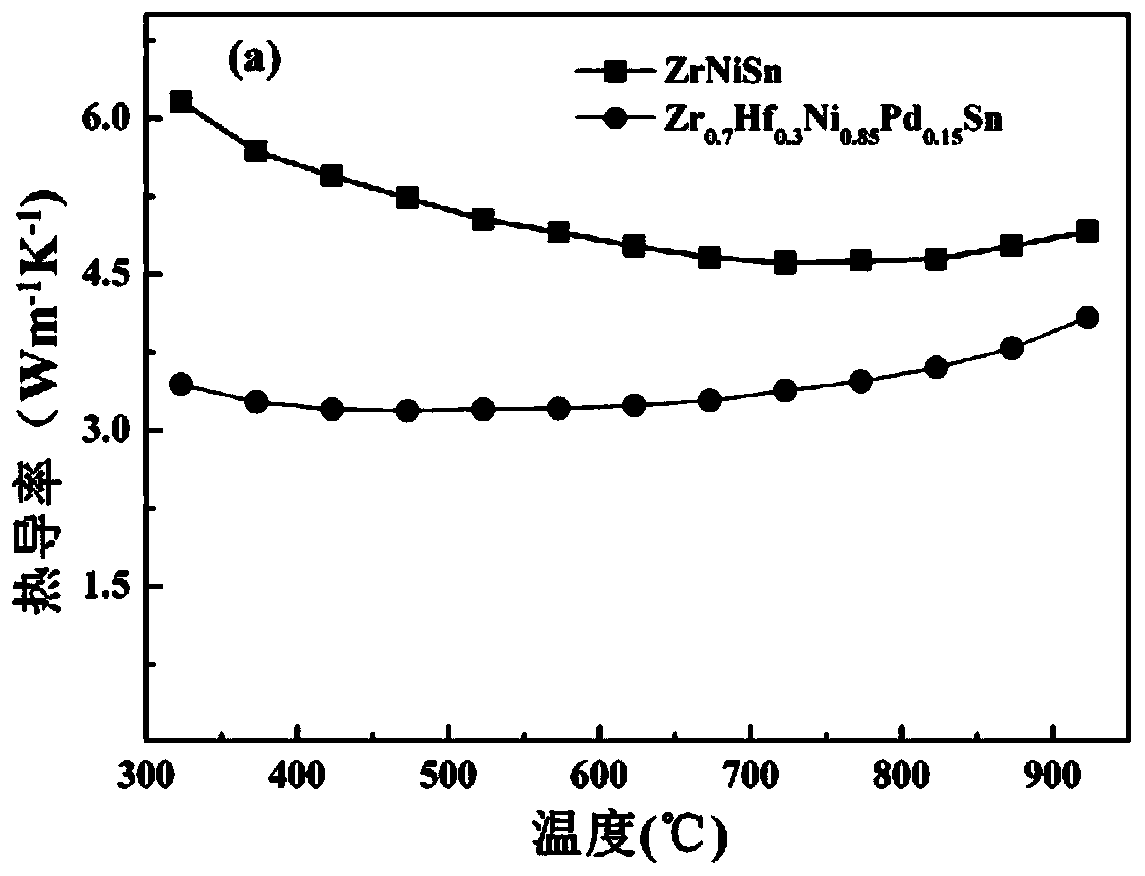

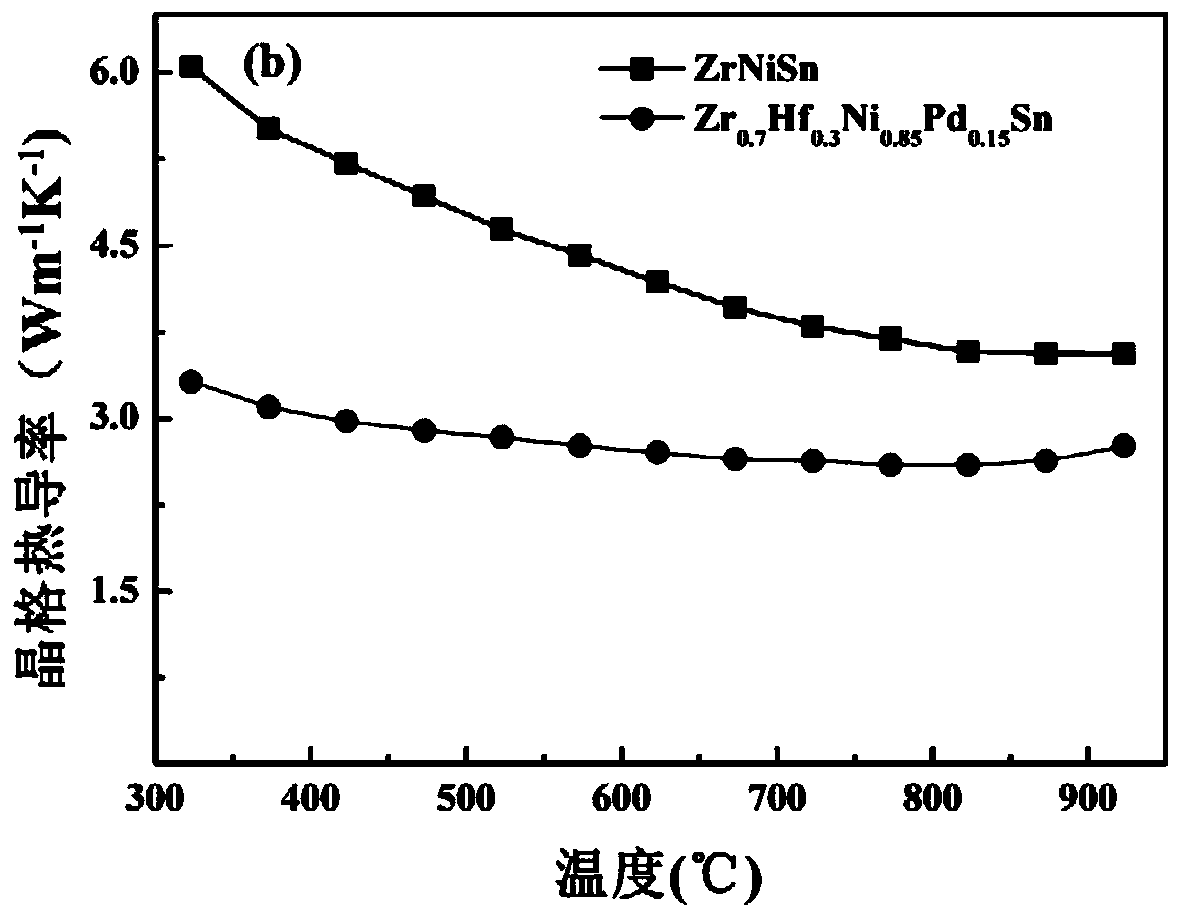

[0025] This embodiment discloses a low-lattice thermal conductivity high-entropy Heusler thermoelectric material, according to the master alloy Zr 0.7 f 0.3 Ni 0.85 PD 0.15 The nominal composition of Sn is batched and smelted, and the atomic percentage of each element is: Zr: 23.3%; Hf: 10%; Ni: 28.3%; Pd: 5%; Sn: 33.3%.

[0026] A further improvement of the present invention is:

[0027] The grain size of the Half-Heusler thermoelectric material with low lattice thermal conductivity obtained after ball milling is 0.5-2 μm.

[0028] A processing method of a low-lattice thermal conductivity high-entropy Heusler alloy, comprising the following steps:

[0029] (1) In the glove box according to the master alloy Zr 0.7 f 0.3 Ni 0.85 PD 0.15 Nominal compositional batching of Sn.

[0030] (2) Melting: Using a magnetic levitation melting furnace, under an argon protective atmosphere (10 4 -10 5 Pa), heat up to 1600-1800°C and keep warm for 3 minutes. In order to ensure the ...

Embodiment 2

[0040] A further improvement of the present invention is:

[0041] A processing method of a low-lattice thermal conductivity high-entropy Heusler alloy, comprising the following steps:

[0042] (1) In the glove box according to the master alloy Zr 0.6 f 0.4 Ni 0.8 PD 0.2 Nominal compositional batching of Sn.

[0043] (2) Melting: Using a magnetic levitation melting furnace, under an argon protective atmosphere (10 4 -10 5 Pa), heat up to 1600-1800°C and keep warm for 4 minutes. In order to ensure the uniformity of the structure after smelting, repeat smelting 5 times.

[0044] (3) Ball milling: firstly, use a mortar to roughly grind the ingot into a powder with a particle size of 0.1-1 mm. Then wet ball milling was performed under an argon atmosphere. The ball milling medium is absolute ethanol, the ball-to-material ratio is 20:1, the rotational speed is 600r / min, and the ball milling time is 8h.

[0045] (4) Drying treatment: the powder after suction filtration was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com